Antistatic UV solvent-free optical cement, preparation method thereof and touch display screen

An antistatic agent and antistatic technology, applied in the field of optical glue, can solve the problems of electrostatic adsorption, dust collection, cremation discharge, touch failure, burning, etc., and achieve the effect of eliminating static electricity, less process and better economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

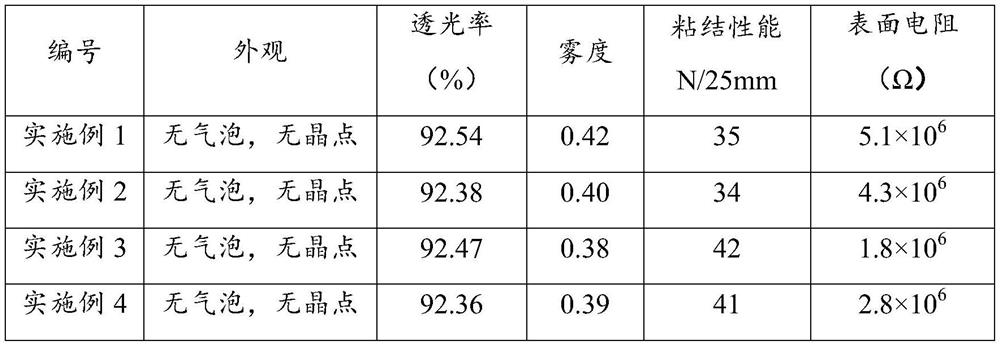

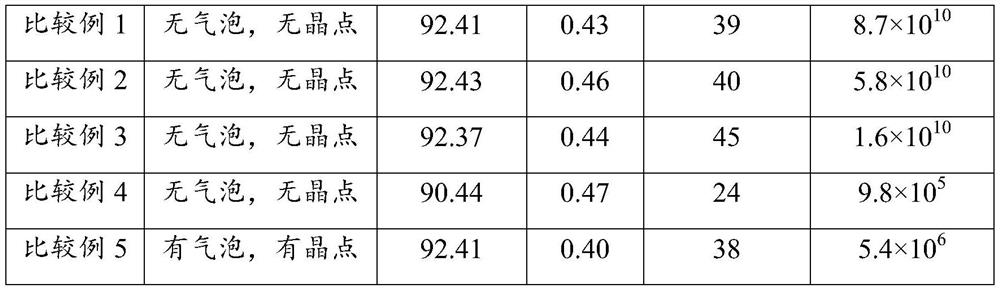

Examples

preparation example Construction

[0056] The present invention also provides a preparation method of the antistatic UV solvent-free optical glue, comprising the steps of:

[0057] After the mixture of each component is coated to form a film, UV curing is carried out.

[0058] In a specific embodiment of the present invention, the conditions of the ultraviolet curing include: the wavelength is 280-420nm, the energy is 500-5000mj / cm 2 .

[0059] In actual operation, the methods of coating and film formation include spray coating, blade coating, spin coating, etc., which can realize the uniform coating of the mixture of each component on the surface of the substrate. The substrate can be a conventional substrate, and the optical adhesive can be removed after curing.

[0060] The present invention also provides a touch display screen, including any one of the antistatic UV solvent-free optical glue.

Embodiment 1

[0062] The antistatic UV solvent-free optical adhesive of the present embodiment is mainly made of the following components in parts by weight:

[0063] 50 parts epoxy acrylate Miamer PS2500, 18 parts polyester acrylate Miamer SC6300, 30 parts tridecyl acrylate, 1.5 parts methyl benzoylformate, 0.3 parts vinyltriethoxysilane and 0.2 parts stearin Trimethyl quaternary ammonium hydrochloride.

[0064] The preparation method of described antistatic UV solvent-free optical glue, comprises the steps:

[0065] The above-mentioned components were mixed in proportion to prepare a mixed liquid, which was coated and cured by an ultraviolet lamp to obtain an optical adhesive (OCA) with a thickness of 50 μm. Among them, the conditions for UV curing include: using UV light with a wavelength of 280-420nm and an energy of 500mj / cm 2 .

Embodiment 2

[0067] The antistatic UV solvent-free optical adhesive of the present embodiment is mainly made of the following components in parts by weight:

[0068] 48 parts of epoxy acrylate Miamer PS4040, 20 parts of polyester acrylate Miamer PE110, 30 parts of caprolactone acrylate, 0.6 parts of 2-hydroxy-2-methylphenylpropan-1-one, 0.5 parts of dimethyl dimethyl oxysilane and 0.9 parts stearamidopropyl hydroxyethyl quaternary ammonium nitrate.

[0069] The preparation method of described antistatic UV solvent-free optical glue, comprises the steps:

[0070] The above-mentioned components were mixed in proportion to prepare a mixed solution, which was coated and cured by an ultraviolet lamp to obtain an optical adhesive (OCA) with a thickness of 75 μm. Among them, the conditions for UV curing include: using UV light with a wavelength of 280-420nm and an energy of 800mj / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com