Water-based alkyd acrylic hybrid resin and preparation method thereof

An alkyd acrylic and hybrid resin technology, applied in the direction of coating, can solve the problems of low performance such as water resistance, and achieve the effect of improving hardness and improving heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The invention provides a kind of preparation method of waterborne alkyd acrylic hybrid resin, comprises the following steps:

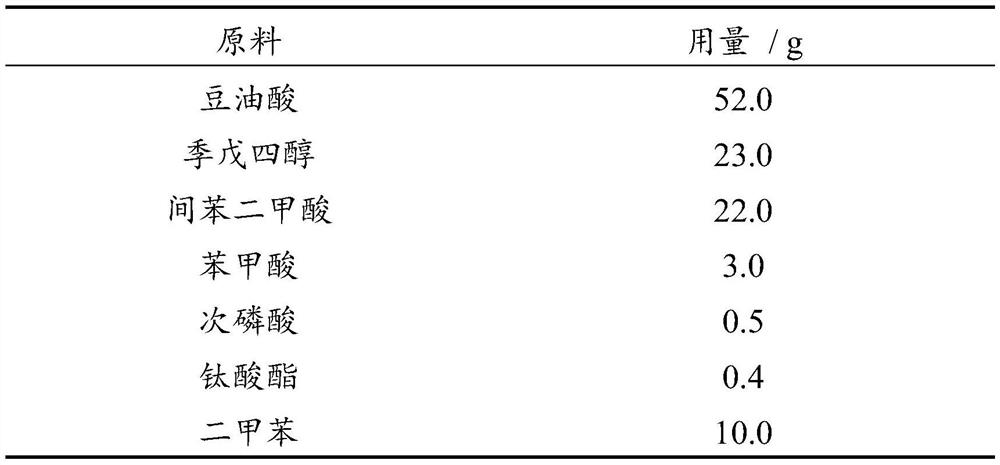

[0041] (1) Preparation of basic alkyd resin, its raw material composition and proportioning ratio are shown in Table 1.

[0042] The preparation method is as follows: add raw materials into a clean reaction kettle, raise the temperature to 180° C. under a nitrogen atmosphere, keep the temperature constant for 1 hour, and collect the condensed water azeotroped with xylene at the same time. Continue to raise the temperature to 225°C, keep the temperature constant until the raw material becomes transparent and clear, then continue to raise the temperature to 245°C until the acid value of the alkyd resin is reduced to less than 10mgKOH / g, then cool down, dilute and discharge to obtain the basic alkyd resin.

[0043] Table 1 Raw material composition and ratio of basic alkyd resin

[0044]

[0045] (2) Preparation of fatty acid modified acrylic ac...

Embodiment 2

[0055] The invention provides a kind of preparation method of waterborne alkyd acrylic hybrid resin, comprises the following steps:

[0056] (1) preparation of basic alkyd resin, its preparation method is the same as embodiment 1.

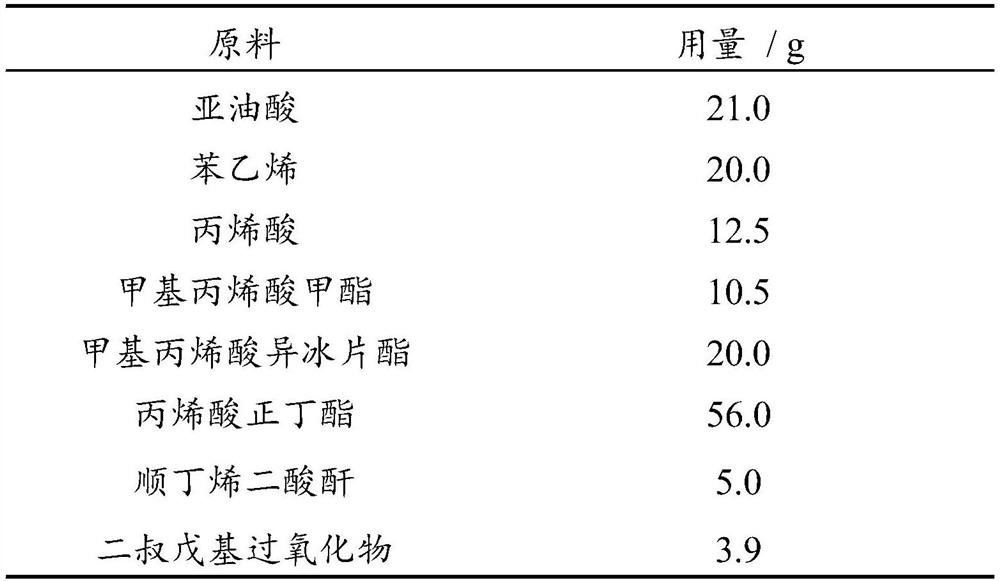

[0057] (2) Preparation of fatty acid modified acrylic acid prepolymer, its raw material composition and proportioning ratio are shown in Table 4.

[0058] The preparation method is as follows: xylene with a total mass of each raw material of 18wt% is used as a solvent at the bottom of the tank, after the raw materials are uniformly mixed, the mixture is added dropwise into the reaction kettle at 140° C., and the dropping time is 6 hours. After the dropwise addition, react at a constant temperature of 140° C. for 2 hours, cool down and discharge to obtain a fatty acid-modified acrylic acid prepolymer.

[0059] Table 4 Raw material composition and proportioning of fatty acid modified acrylic acid prepolymer

[0060]

[0061]

[0062] (3) Prep...

Embodiment 3

[0067] The invention provides a kind of preparation method of waterborne alkyd acrylic hybrid resin, comprises the following steps:

[0068] (1) Preparation of basic alkyd resin, its raw material composition and proportioning ratio are shown in Table 6.

[0069] The preparation method is as follows: add raw materials into a clean reaction kettle, raise the temperature to 180° C. under a nitrogen atmosphere, keep the temperature constant for 1 hour, and collect the condensed water azeotroped with xylene at the same time. Continue to raise the temperature to 225°C, keep the temperature constant until the raw material becomes transparent and clear, then continue to raise the temperature to 245°C until the acid value of the alkyd resin is reduced to less than 10mgKOH / g, then cool down, dilute and discharge to obtain the basic alkyd resin polymer.

[0070] Table 6 Raw material composition and ratio of basic alkyd resin

[0071]

[0072]

[0073] (2) Preparation of fatty acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com