Production device for degradable polypropylene plastics and preparation method of degradable polypropylene plastics

A technology for polypropylene plastics and production equipment, which is applied in the field of plastics production, can solve problems such as inability to mix and stir, and is not conducive to improving the quality of degradable polypropylene plastics, so as to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

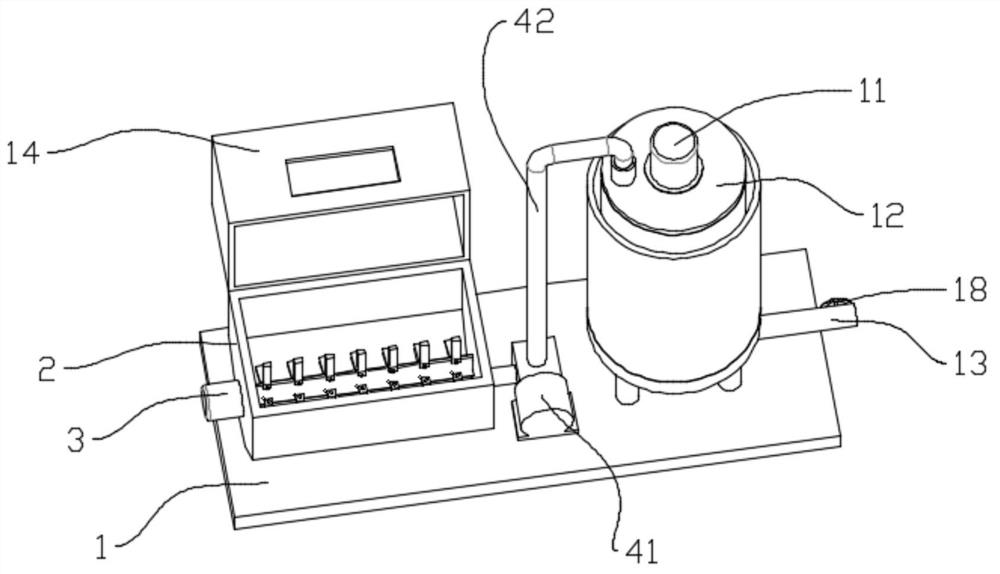

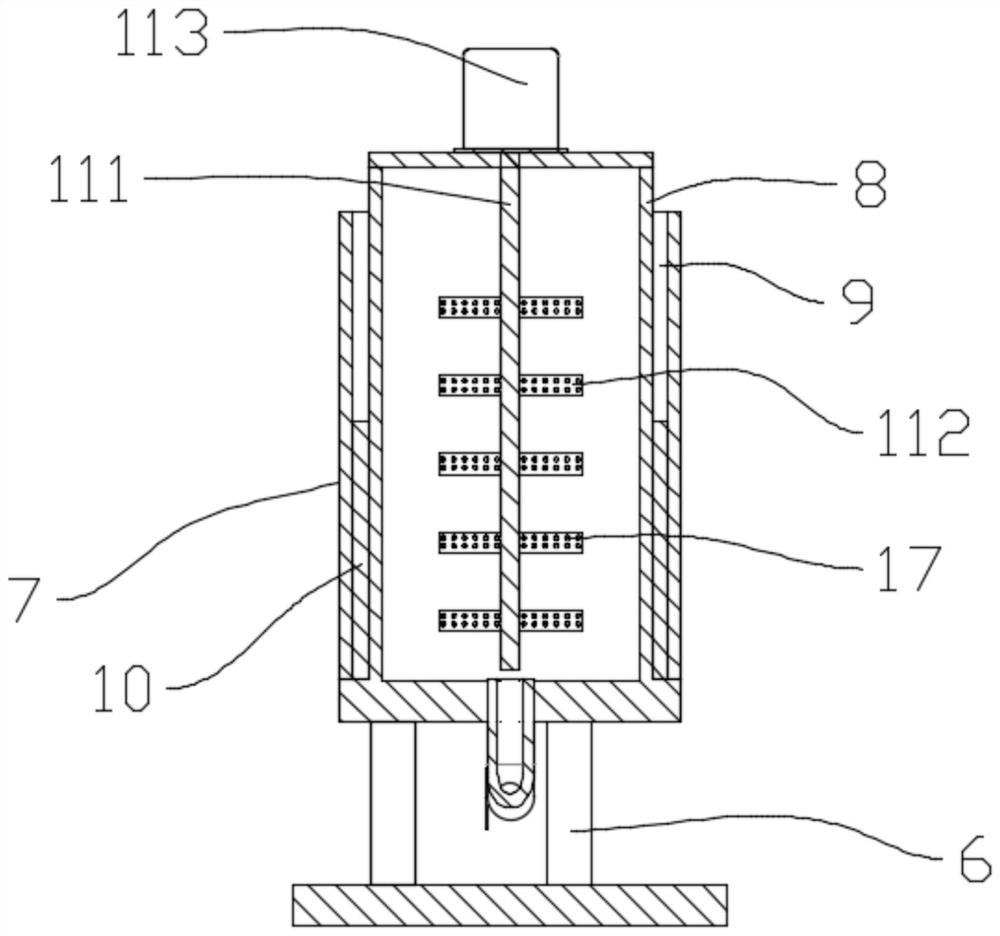

[0031] A production device for degradable polypropylene plastics, comprising a bottom plate 1, a mixing box 2 is fixedly installed on the upper surface of the bottom plate 1, a mixing mechanism 3 is arranged inside the mixing box 2, and the mixing mechanism 3 is installed on the surface of the mixing box 2 through a bearing On one side of the mixing box 2, there is a feeding mechanism 4, the feeding mechanism 4 is fixedly installed on the upper surface of the bottom plate 1, and the bottom of the mixing box 2 is fixedly installed with the first discharge pipe 5, the first discharge pipe 5 Connected with the feeding mechanism 4, one side of the feeding mechanism 4 is provided with a mounting frame 6, and a reaction kettle 7 is fixedly installed on the mounting frame 6, and a heating tank 8 is provided in the reaction kettle 7, and the inside of the reaction kettle 7 is connected to the reaction The outside of still 7 is provided with installation cavity 9, is provided with heate...

Embodiment 2

[0047] A preparation method of degradable polypropylene plastic, the preparation method of degradable polypropylene plastic specifically comprises the following steps:

[0048] Step 1. Prepare raw materials: take 52 parts of polypropylene, 22 parts of starch, 9 parts of lignin fiber, 3.5 parts of coupling agent, 6 parts of methyl silicone oil and 8 parts of talcum powder according to the parts by mass;

[0049] Step 2, primary material mixing: put polypropylene, starch, lignin fiber and talcum powder into the mixing box 2 for full mixing, and transport them to the reaction kettle 7 through the conveying mechanism 4;

[0050] Step 3, heating and stirring: heating to 85 degrees Celsius by the heater 10 to increase the temperature in the reactor 7, starting the stirring mechanism 11 to stir and heat for 15 minutes to obtain the mixture;

[0051] Step 4. Mixing of secondary materials: put coupling agent and methyl silicone oil into the reaction kettle 7 and mix with the mixture, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com