Hydrogen energy automobile bipolar plate ultrahigh-speed precision welding process and welding clamp thereof

A technology of precision welding and welding fixtures, which is applied in welding equipment, manufacturing tools, laser welding equipment, etc., to achieve the effect of increasing the welding strength of the weld seam, stabilizing the welding process, and increasing the welding contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

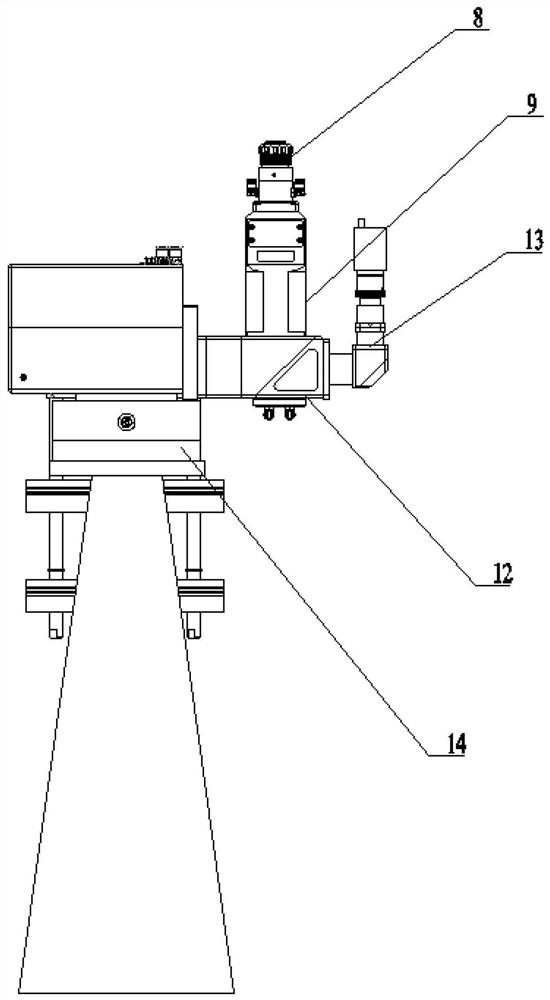

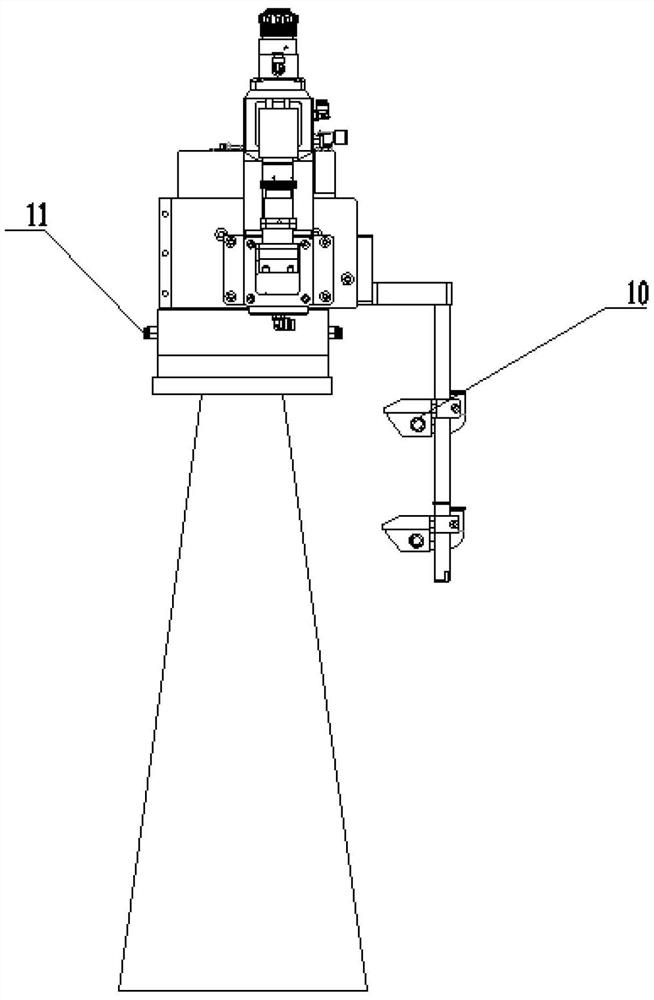

[0049] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

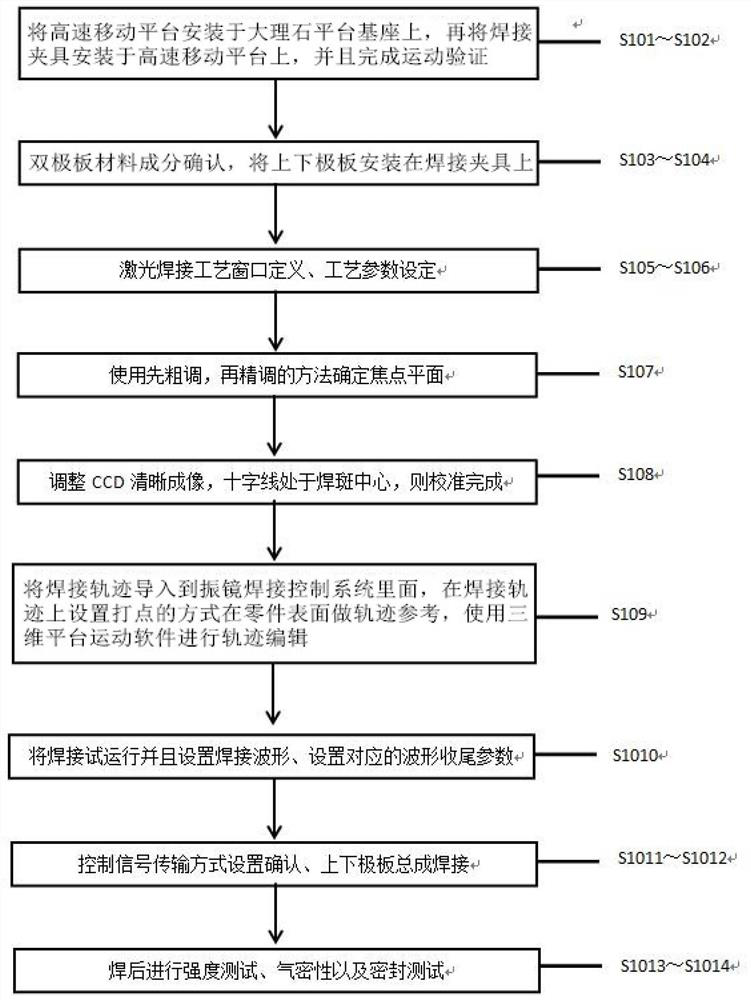

[0050] Such as Figure 1 to Figure 17 As shown, a hydrogen energy vehicle bipolar plate ultra-high-speed precision welding process, the steps include:

[0051] S101, high-speed mobile platform installation: install the high-speed mobile platform on the marble platform base;

[0052] S102, Welding fixture installation: install and fix the welded fixture after design and processing on the high-speed mobile platform of the marble platform base, and check whether the installation of each mechanism is completed and whether the movement is normal;

[0053] S103, material confirmation: confirm the material by using an alloy element analysis instrument. In this implementation case, titanium alloy is used for welding. The thickness of the upper plate is 0.1mm, and the thickness of the lower plate is 0.1mm, and the lower plate is required not to be welded through;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com