Comprehensive treatment device for tail gas of heating furnace

A comprehensive treatment and heating furnace technology, applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve problems such as large floor space, affecting desulfurization efficiency, uneven mixing, etc., to reduce construction costs, improve desulfurization efficiency, good mix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

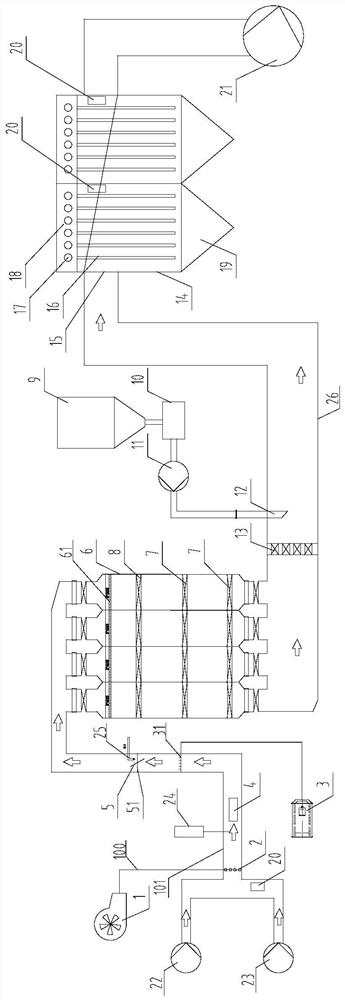

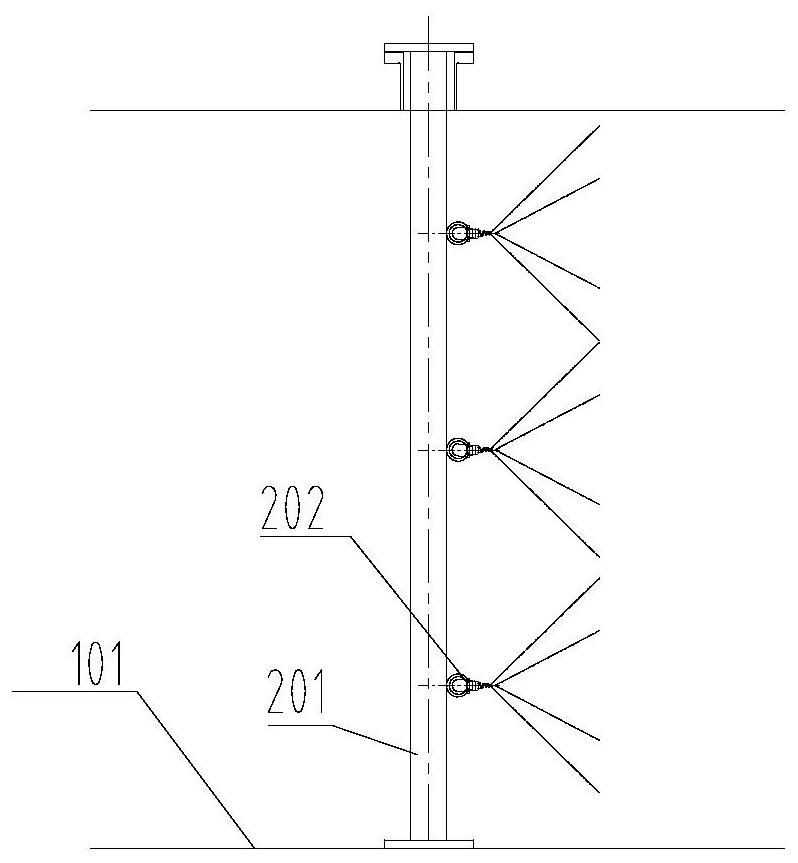

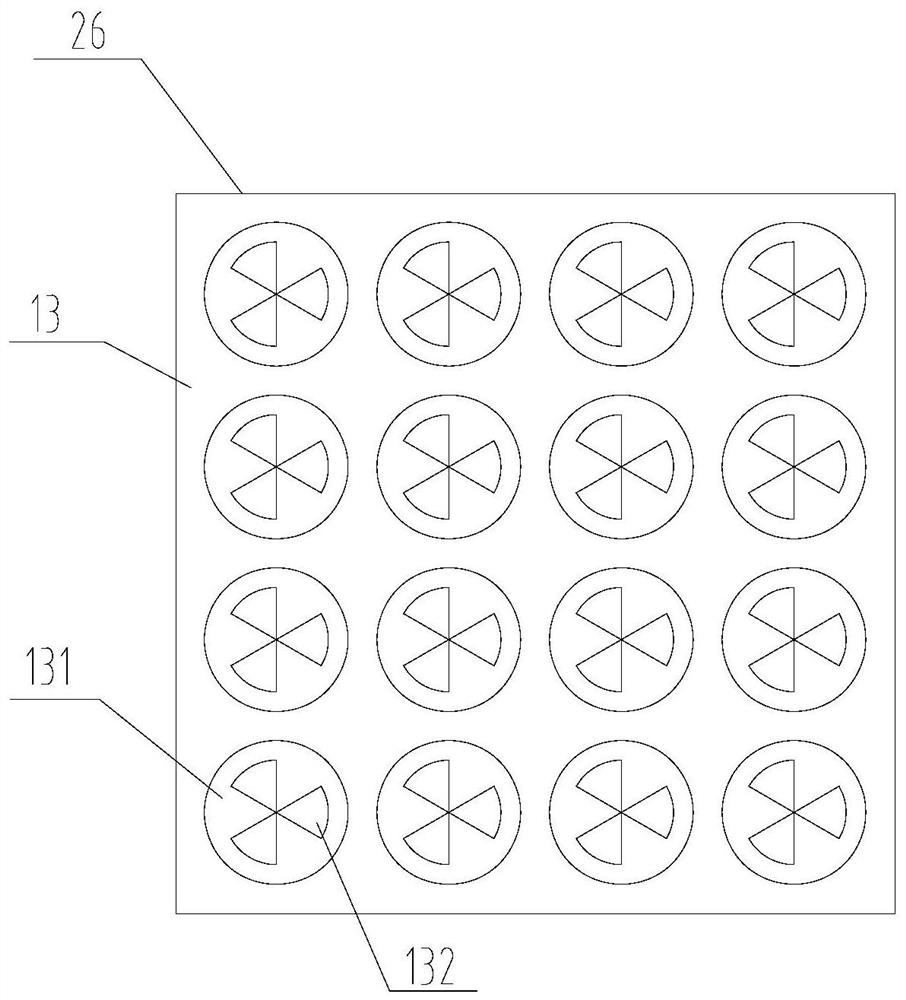

[0024] refer to Figure 1 to Figure 3 , a comprehensive treatment device for heating furnace tail gas in the present invention, comprising a mixing flue 101, a low-temperature SCR reactor 6, a desulfurization flue 26 and a bag filter 14 arranged in sequence along the flue gas conveying direction, the input of the mixing flue 101 The end has two flue branches, and the confluence point of the two flue branches is connected to the dilution fan 1. The mixing flue 101 is provided with a uniform device and an ammonia injection pipe 25, and the dilution fan 1 passes through the blowing pipe 100. Connected with the uniform device, the ammonia injection pipe 25 is arranged upstream of the uniform device, the ammonia injection pipe 25 is connected with the reducing agent injection system, and the mixing flue 101 is also connected with a tail gas heating device, the The output end of the mixing flue 101 is connected to the inlet of the low-temperature SCR reactor 6, and the outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com