Cable production equipment

A technology for production equipment and cables, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of affecting the use effect of cable production equipment, poor applicability of cable production equipment, poor effect of adjusting cutting angle, etc., to achieve convenient multi-angle The effect of cutting, improving the range of use, and facilitating position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

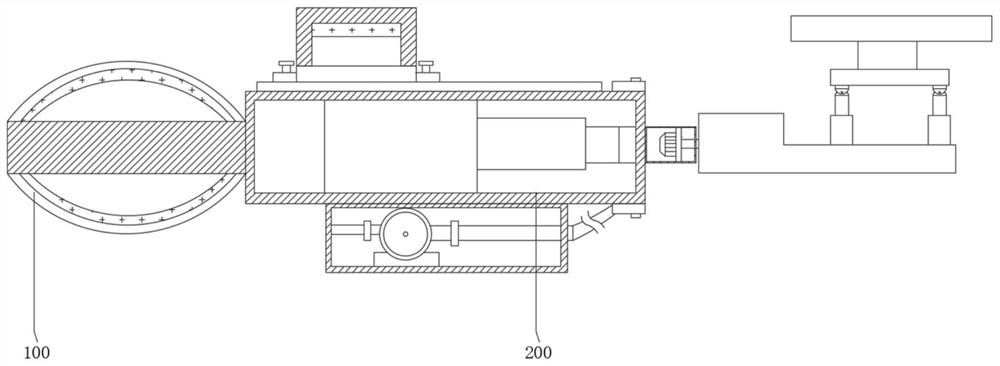

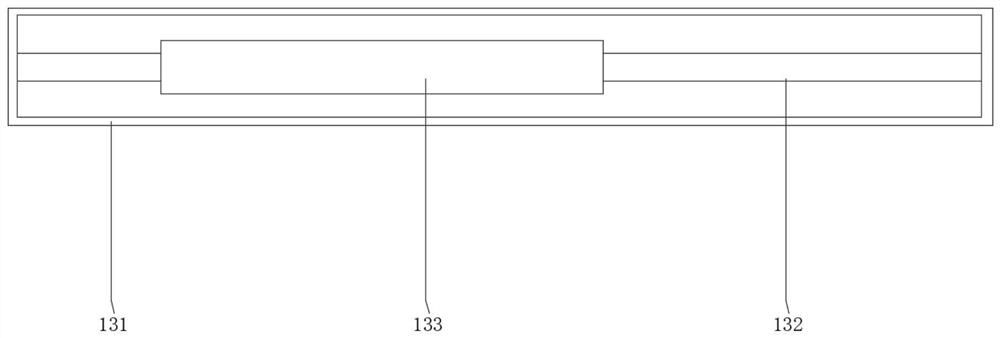

[0035] see Figure 1-4 , the present invention provides a technical solution: a cable production equipment includes a base 100 and a cutting assembly 200, the base 100 is used to support and fix the cutting assembly 200, which is convenient for the adjustment and use of the cutting assembly 200, and is convenient for multi-angle cutting of cables processing.

[0036] see Figure 1-Figure 3 , the base 100 includes a box body 110, a handle 120 and an armrest 140. The handle 120 is fixed on one side of the box body 110 for easy grasping. The armrest 140 is slidably connected to the top of the box body 110 for easy adjustment of the position of the armrest 140. The box body One side of 110 is provided with an opening, which is convenient for cleaning the inside of the box body 110. The handle 120 includes a handle 121 and a hand guard 122. One end of the handle 121 is fixed to the side of the box 110, and one end of the handle 121 is fixed to the box by welding. 110 side, the guar...

Embodiment 2

[0039] see Figure 1-4 , the present invention provides a technical solution: a cable production equipment includes a base 100 and a cutting assembly 200, the base 100 is used to support and fix the cutting assembly 200, which is convenient for the adjustment and use of the cutting assembly 200, and is convenient for multi-angle cutting of cables processing.

[0040] see Figure 1-Figure 3 , the base 100 includes a box body 110, a handle 120 and an armrest 140. The handle 120 is fixed on one side of the box body 110 for easy grasping. The armrest 140 is slidably connected to the top of the box body 110 for easy adjustment of the position of the armrest 140. The box body One side of 110 is provided with an opening, which is convenient for cleaning the inside of the box body 110. The handle 120 includes a handle 121 and a hand guard 122. One end of the handle 121 is fixed to the side of the box 110, and one end of the handle 121 is fixed to the box by welding. 110 side, the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com