Calculation method and device for dynamic delay time of exhaust gas recirculation system

A recirculation system and dynamic delay technology, applied in electrical control, engine control, machine/engine, etc., can solve the problems of EGR rate calculation lag, difficulty in fully exerting EGR fuel-saving effect, and inaccurate calculation of engine EGR gas volume. Achieve the effect of improving performance and utilization, and improving the accuracy of calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

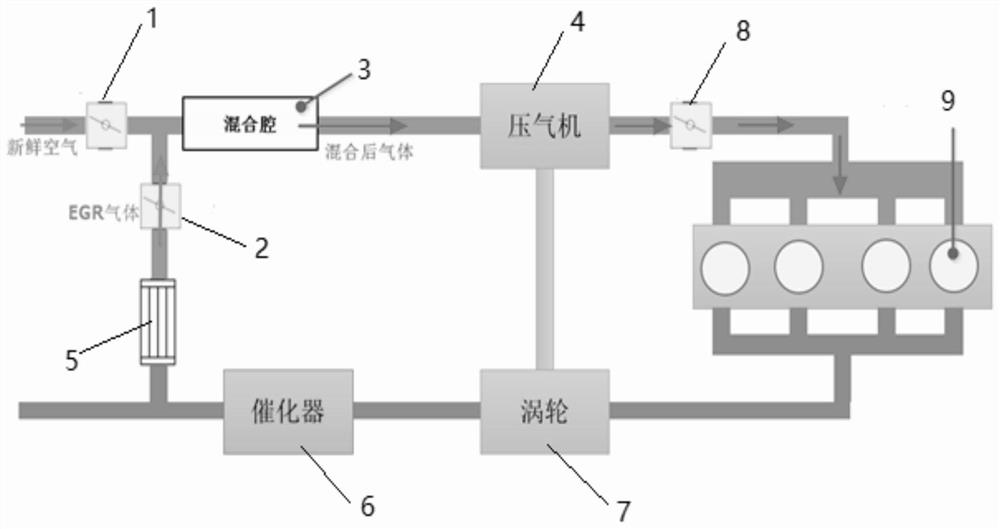

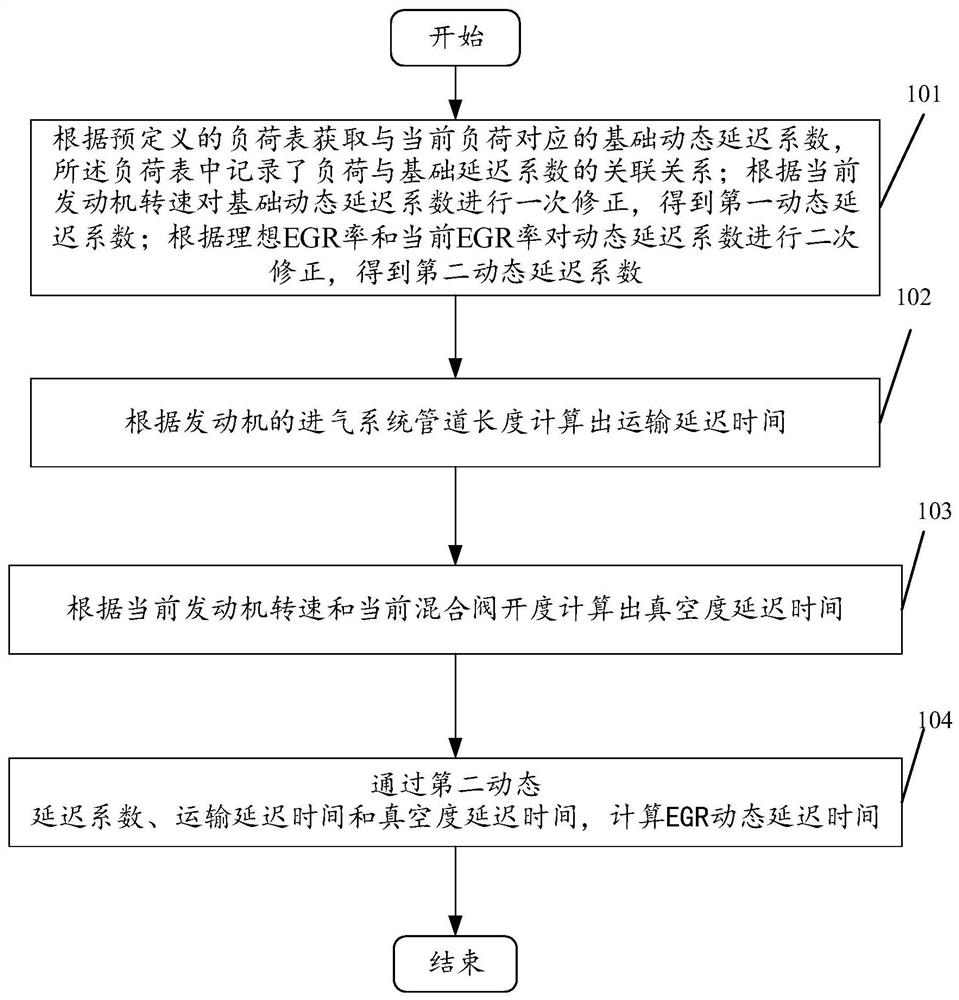

[0073] see image 3 , image 3 This is a schematic flowchart of a method for calculating a dynamic delay time of an exhaust gas recirculation system disclosed in an embodiment of the present invention. in, image 3 The described method can be applied to an exhaust gas recirculation system, the exhaust gas recirculation system includes a mixing valve, an EGR valve and a mixing chamber, and the fresh air output from the mixing valve and the EGR gas output from the EGR valve are mixed in the mixing chamber and then output to the mixing chamber. In the compressor, other structures or systems capable of mixing the fresh air output by the mixing valve with the EGR gas output by the EGR valve are not limited in the embodiments of the present invention. like image 3 As shown, the method for calculating the dynamic delay time of the exhaust gas recirculation system may include the following operations:

[0074] 101. Obtain the basic dynamic delay coefficient corresponding to the c...

Embodiment 2

[0130] see Figure 4 , Figure 4 The described method can be applied to an exhaust gas recirculation system, the exhaust gas recirculation system includes a mixing valve, an EGR valve and a mixing chamber, and the fresh air output from the mixing valve and the EGR gas output from the EGR valve are mixed in the mixing chamber and then output to the mixing chamber. The compressor, wherein other structures or systems capable of mixing the fresh air output by the mixing valve with the EGR gas output by the EGR valve are not limited in the embodiments of the present invention. like Figure 4 As shown, the method for calculating the dynamic delay time of the exhaust gas recirculation system may include the following operations:

[0131] 201. Obtain a basic dynamic delay coefficient corresponding to the current load according to a predefined load table, in which the load table records the relationship between the load and the basic delay coefficient; perform a correction on the bas...

Embodiment 3

[0193] see Figure 5 , Figure 5 A block diagram of a calculation flow of an EGR dynamic delay time disclosed in an embodiment of the present invention. in, Figure 5 The described method can be applied to an exhaust gas recirculation system, the exhaust gas recirculation system includes a mixing valve, an EGR valve and a mixing chamber, and the fresh air output from the mixing valve and the EGR gas output from the EGR valve are mixed in the mixing chamber and then output to the compressed air. The embodiment of the present invention is not limited to other structures or systems capable of mixing the fresh air output by the mixing valve with the EGR gas output by the EGR valve. As shown in the figure, the specific implementation is as follows:

[0194] Step (1): First, obtain the basic dynamic delay coefficient corresponding to the current load according to a predefined load table, in which the relationship between the load and the basic delay coefficient is recorded; the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com