A crystal processing device and method

A technology for processing devices and crystals, applied to fine working devices, working accessories, manufacturing tools, etc., can solve the problems of unusable cutting surfaces, low efficiency, waste of labor, etc., to improve cracking efficiency, reduce the number of collisions, and observe the results Accurate and objective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

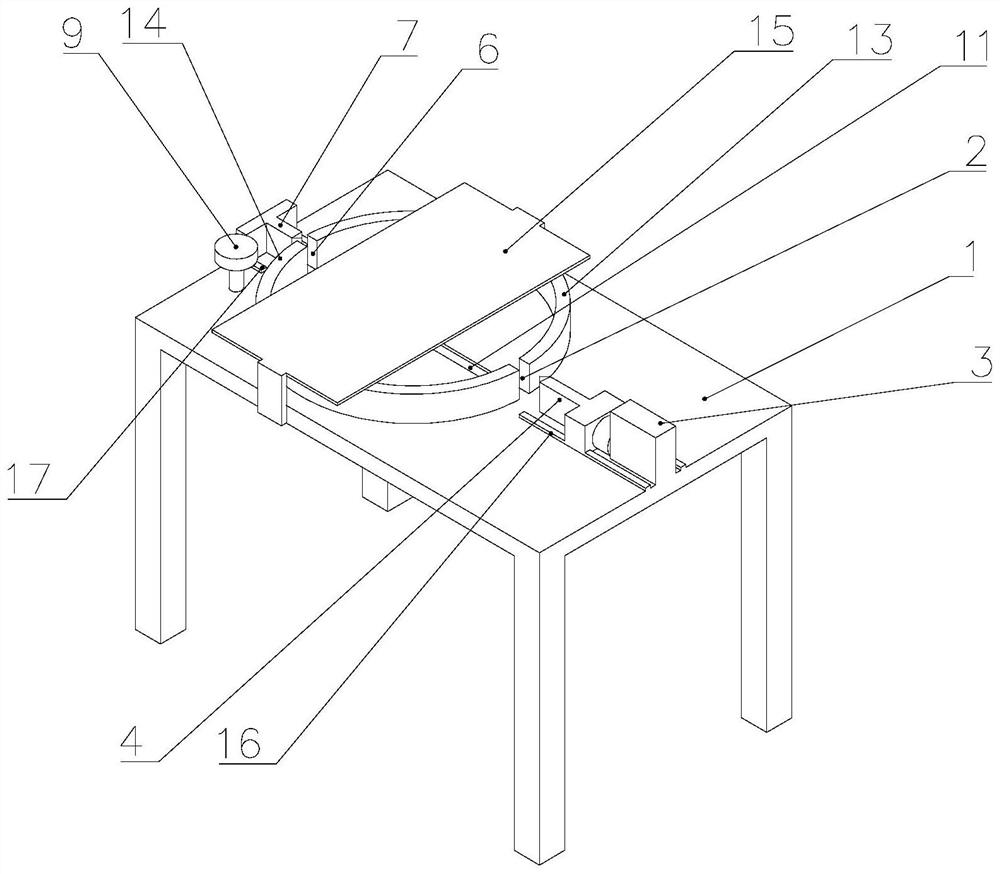

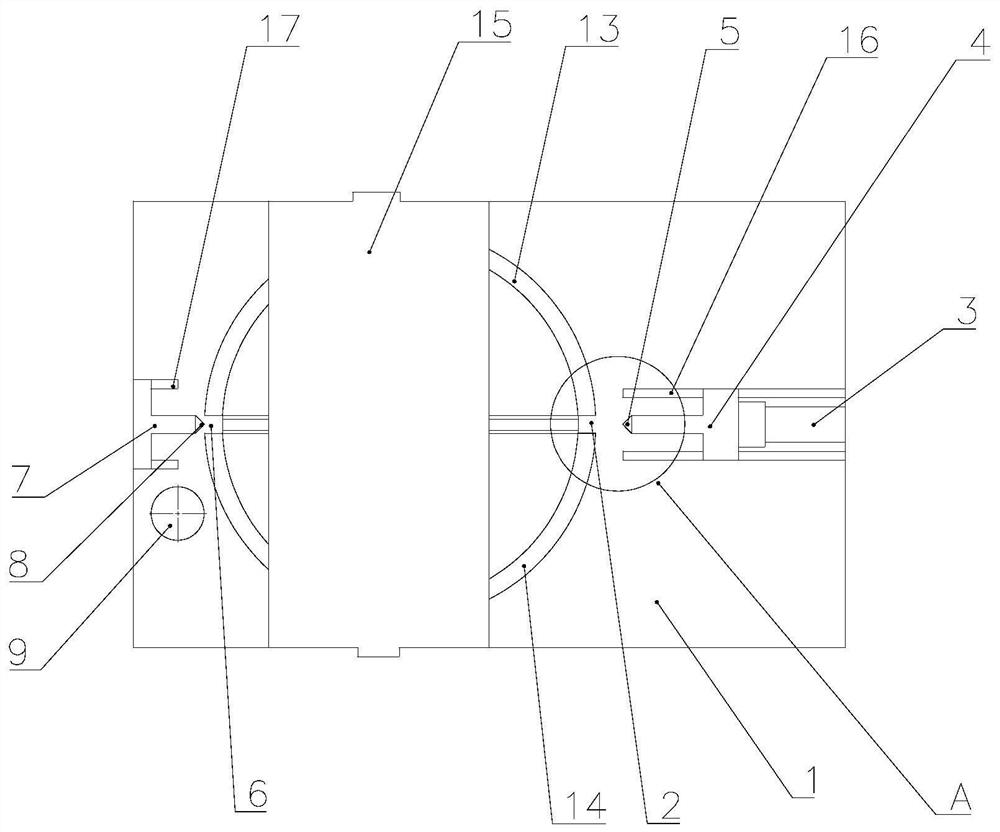

[0054] like Figure 1-4 As shown, embodiments of the present application disclose a crystal processing apparatus, which includes a frame and a collision assembly. Wherein, a base 1 is installed on the frame, and a clamping mechanism for clamping the crystal is arranged on the base 1, and the clamping mechanism includes a first opening 2; the collision assembly is arranged on the outer side of the clamping mechanism, and the collision assembly includes a first opening 2. The collision piece and the first power mechanism 3, the first power mechanism 3 is used to drive the first collision piece to move, and passes through the first opening 2 to strike the crystal until the crystal is cracked. By setting a clamping mechanism, the crystal is fixed to prevent the crystal from sliding when it is subjected to a large collision force, so as to ensure the successful cracking of the crystal; by setting the first power mechanism 3 to drive the first collision piece to move, so that the fi...

Embodiment approach

[0071]As an embodiment, the clamping mechanism includes a first clamping member 13 and a second clamping member 14. The first clamping member 13 and the second clamping member 14 are respectively installed on the base 1. The base 1, the second clamping member 14 A holding member 13 and a second holding member 14 form an accommodating cavity for placing the crystal, and the gap between the first holding member 13 and the second holding member 14 forms a first opening 2 and a second opening 6 respectively; At least one of the first clamp 13 and the second clamp 14 is capable of adjusting the relative position with respect to the other. By arranging at least one of the first clamping member 13 and the second clamping member 14 to be able to adjust the relative position relative to the other, the crystal processing device can be used to process crystals of different sizes, and the applicability of the crystal processing device is improved. sex.

[0072] Specifically, in order to ...

Embodiment 2

[0079] Embodiment 2 of the present application provides a crystal processing method, which can be implemented by using the crystal processing device provided in Embodiment 1, including the following steps:

[0080] (1) Open the pressing plate 15, place the crystal in the accommodating cavity, overlap the center line of the crystal with the heating wire 10, and make the first clamping member 13 and the second clamping member 14 cooperate with each other to clamp the crystal;

[0081] (2) Start the heating motor 12 so that the heating rate of the heating wire 10 is 0.8-3°C / s, and heat the center line of the crystal. When the center line of the crystal rises to a certain temperature, turn off the motor,

[0082] Wherein, when 10°C≤T≤50, the difference between the central line temperature of the crystal after heating and the initial temperature of the crystal is 30-300°C, where T is the initial temperature of the crystal; or when T>50°C, after heating The difference between the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com