An automatic grinding device for outer surface of steel pipe processing

A technology of outer surface and steel pipe, which is applied in the direction of grinding drive device, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces. Work efficiency, manpower and time saving, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

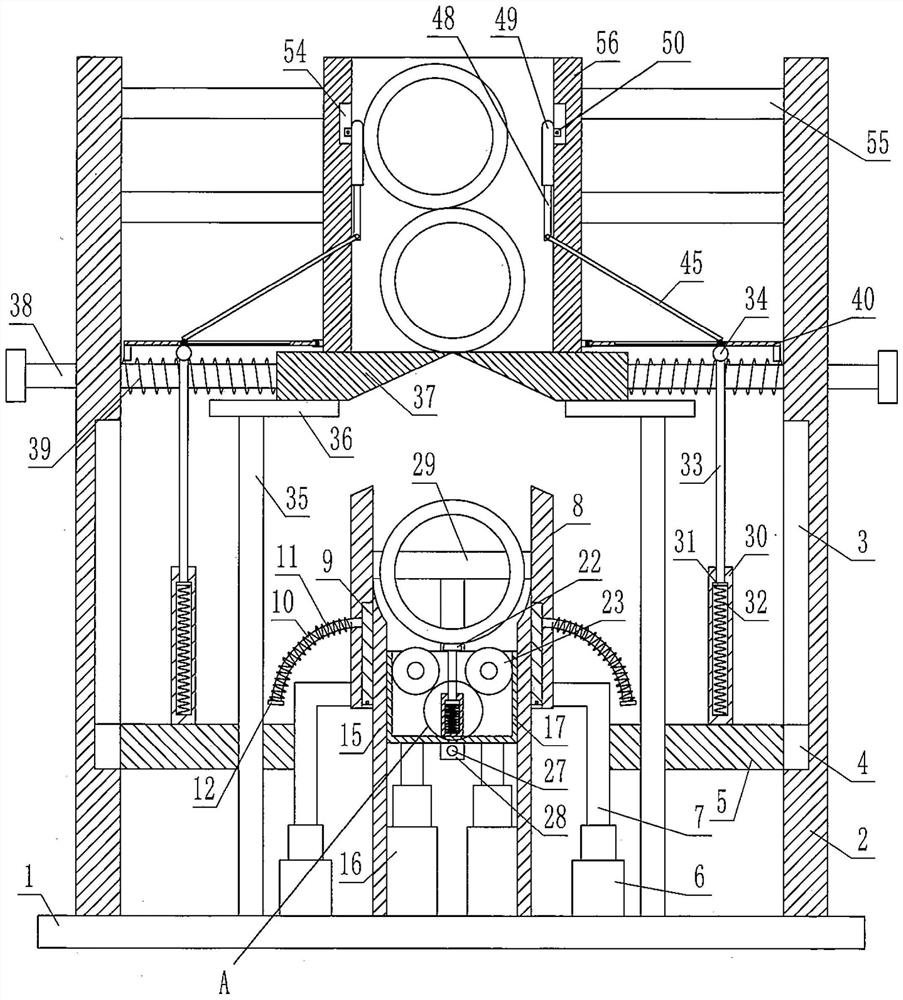

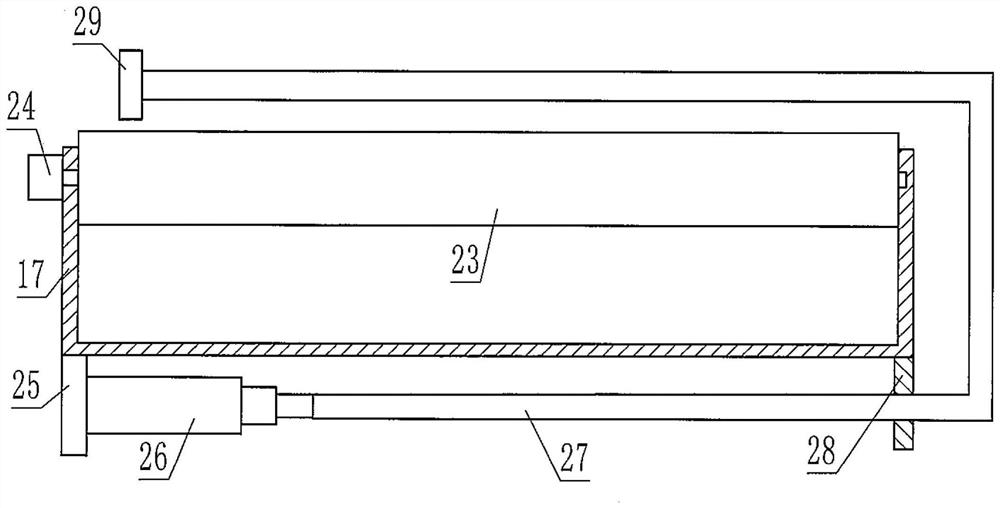

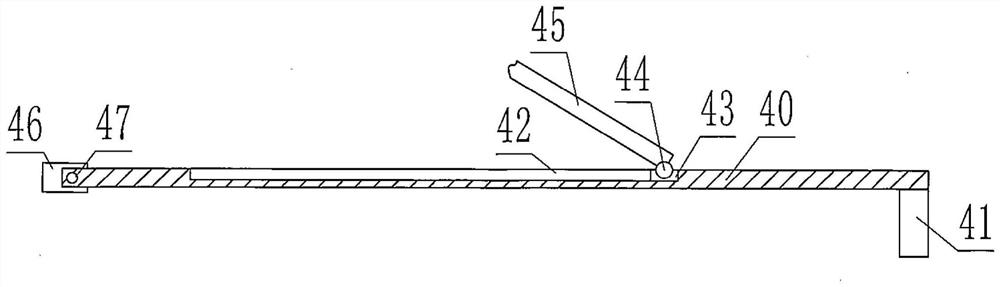

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 as well as Figure 7As shown, an automatic grinding device for the outer surface of steel pipe processing includes a base 1, and fixed plates 2 are fixedly installed on both sides of the top of the base 1, and first dovetails are arranged on the opposite side walls of the two fixed plates 2. slot 3, each first dovetail slot 3 is slidingly connected with a first dovetail block 4, one side of each first dovetail block 4 is fixedly installed with a lifting plate 5, and the top of the base 1 is fixedly installed with two The first hydraulic cylinder 6, the tops of the two first hydraulic cylinders 6 are respectively fixedly equipped with L-shaped lifting plates 7, and the opposite side walls of the two lifting plates 5 are respectively fixedly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com