Additive-free whole cotyledon soymilk and preparation method thereof

An additive-free, soybean milk technology, applied in the field of food science, can solve problems such as large nutrient loss, and achieve the effects of nutritional health, improved gel strength and water retention, and simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

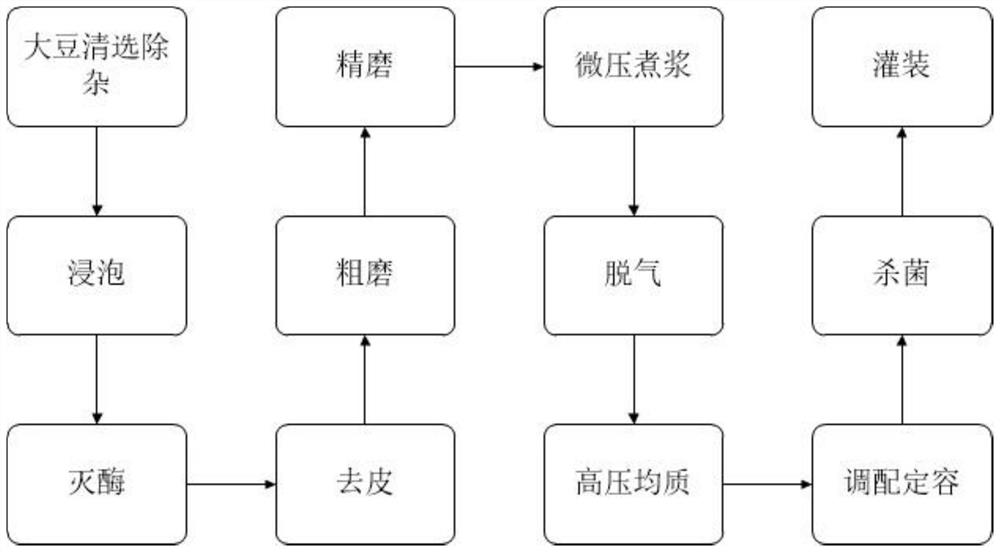

[0024] The first aspect of the present disclosure provides a method for preparing additive-free whole cotyledon soymilk, the method comprising the following steps:

[0025] S1. Cleaning and removing impurities from the bean raw materials to obtain pure beans, soaking the pure beans in demineralized water to obtain soaked beans;

[0026] S2, subjecting the soaked beans to inactivation treatment and peeling treatment to obtain watercress;

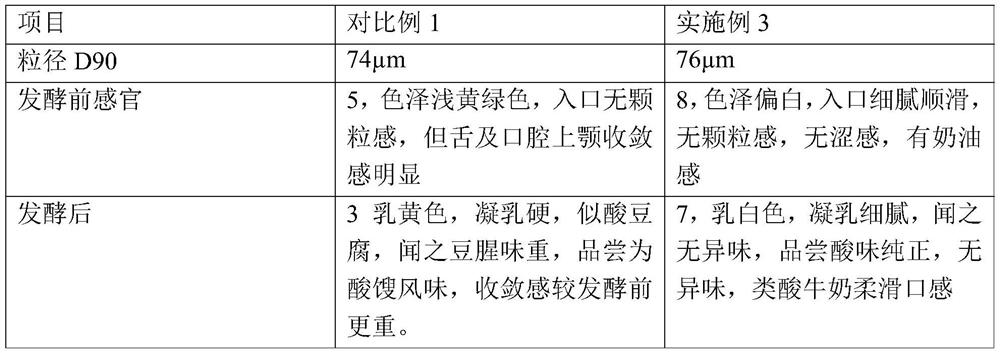

[0027] S3. Roughly grinding the bean paste to obtain a first bean paste, and finely grinding the first bean paste to obtain a second bean paste; the particle size D90 of the first bean paste is below 1000 μm, and the second bean paste is The particle size D90 of the two bean paste is below 150 μm;

[0028] S4. Degassing and first homogenizing the second soybean paste to obtain soybean milk puree; the particle size of D90 in the soybean milk puree is 30-80 μm;

[0029] S5. The soybean milk puree is adjusted to a constant volume and then ster...

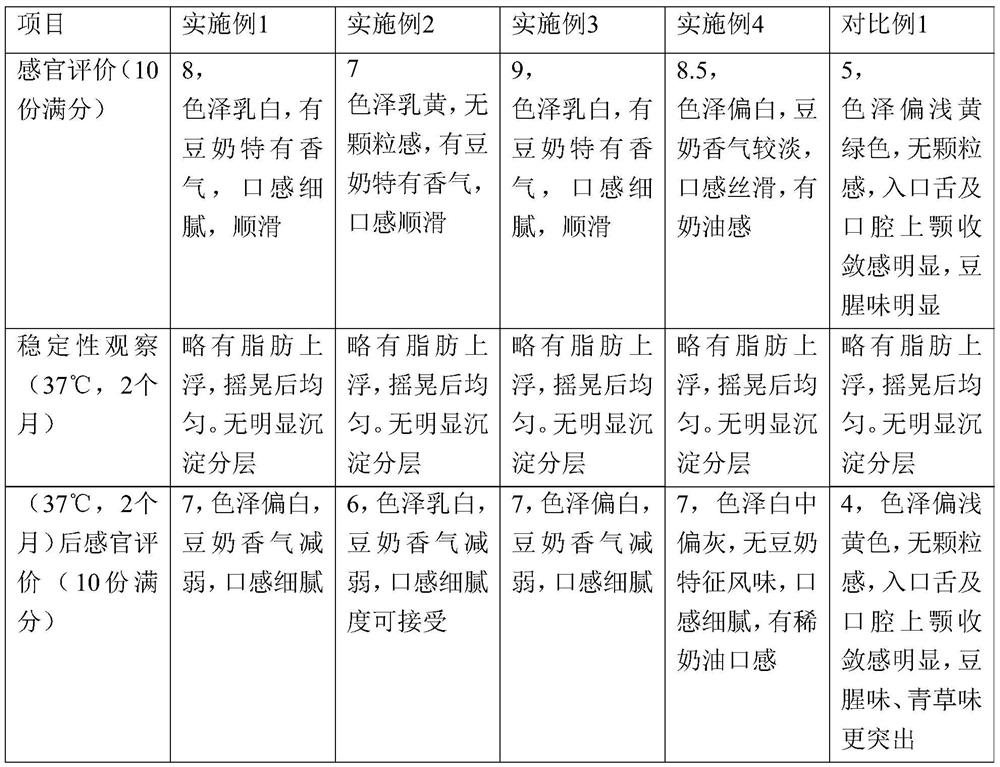

Embodiment 1

[0044] This embodiment provides a kind of whole cotyledons soybean milk, and this soybean milk is prepared by the following steps:

[0045] (1) Wash and remove impurities from the bean raw materials to obtain pure beans. The specific operation steps are: 14 parts of soybeans are removed by a cleaning machine to remove surface dust, stones, metals and bad bean residues to obtain clean soybeans.

[0046] (2) Soaking: Put the soybeans into a soaking bean tank, the ratio of soybeans to water is 1:3, the water temperature is 20°C, and soak for 12 hours.

[0047](3) The soaked beans are subjected to enzyme-inactivating treatment and peeling treatment to obtain watercress. The conditions for enzyme-inactivating treatment are: 95° C., blanching with 3 times of water for 15 minutes.

[0048] (4) The first bean paste is obtained by coarsely grinding the watercress. The conditions for coarse grinding are as follows: using a ceramic mill, grinding at a soybean-to-water ratio of 1:4 and ho...

Embodiment 2

[0056] This embodiment provides a kind of whole cotyledons soybean milk, and this soybean milk is prepared by the following steps:

[0057] (1) Wash and remove impurities from the bean raw materials to obtain pure beans. The specific operation steps are: 7 parts of soybeans are removed by a cleaning machine to remove surface dust, stones, metals and bad bean residues to obtain clean soybeans.

[0058] (2) Soaking: Put the soybeans into the soaking bean tank, the ratio of soybeans to water is 1:3, the water temperature is 15°C, the relative vacuum is -0.03MPa, and soak for 10 hours.

[0059] (3) The soaked beans are subjected to enzyme-inactivating treatment and peeling treatment to obtain watercress. The conditions for enzyme-inactivating treatment are: 95° C., blanching with 3 times of water for 15 minutes.

[0060] (4) The first bean paste is obtained by coarsely grinding the watercress. The conditions for coarse grinding are as follows: using a ceramic mill, grinding at a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com