Wet dehydration method for maintaining flexibility of plant tissue protein

A plant tissue and flexibility technology, which is applied in the field of wet dehydration to maintain the flexibility of plant tissue proteins, can solve the problems of reduced toughness and elasticity, and achieve the effects of reducing hardness, reducing the influence of structure, and strong water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Material mixing: Mix 80 parts of soybean protein isolate, 20 parts of pea protein, 10 parts of glutinous rice flour, and 10 parts of peanut protein to form a mixture;

[0025] (2) Tempering: add sodium alginate and konjac gum solution with a mass concentration of 0.05% to the mixed material in step (1) (the mass ratio of sodium alginate and konjac gum is 1:1), mix and stir, and adjust the content of The amount of water is 50%, the stirring speed is 180r / min, the stirring time is 20min, and stand for 20 hours;

[0026] (3) Extrusion: Extrusion is carried out by twin-screw extrusion process. The process conveying section is 35°C, the melting section is 115°C, and the forming section is 105°C. The cutting speed is controlled at 6cm in length, and the moisture content of the extruded plant tissue protein is 40%;

[0027] (4) Wet cooling: step (3) the extruded plant tissue protein is cooled to 70°C at a humidity of 35%;

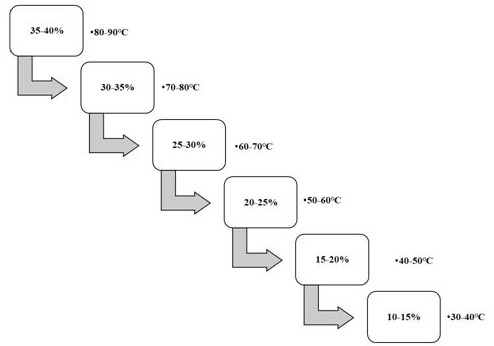

[0028] (5) Gradient dehydration with dehumidifi...

Embodiment 2

[0030] (1) Material mixing: Mix 70 parts of soybean protein isolate, 20 parts of pea protein, 20 parts of glutinous rice flour, and 10 parts of peanut protein powder to form a mixture;

[0031] (2) Tempering: add sodium alginate and konjac gum solution with a mass concentration of 0.8% to the mixed material in step (1) (the mass ratio of sodium alginate and konjac gum is 1:1), mix and stir, and adjust the content of The water content is 40%, the stirring speed is 200r / min, the stirring time is 15min, and it is left to stand for 18~24 hours;

[0032] (3) Extrusion: Extrusion is carried out by twin-screw extrusion process. The conveying section of the process is 30°C, the melting section is 110°C, and the forming section is 100°C. The length of the knife speed is controlled at 3cm, and the moisture content of the extruded plant tissue protein is 35%;

[0033] (4) Wet cooling: step (3) the extruded plant tissue protein is cooled to 60~70°C in the jumping river with a humidity of...

Embodiment 3

[0036] (1) Material mixing: Mix 75 parts of soybean protein isolate, 20 parts of pea protein, 20 parts of glutinous rice flour, and 5 parts of peanut protein powder to form a mixture;

[0037] (2) Tempering: add sodium alginate and konjac gum solution with a mass concentration of 0.05% to the mixed material in step (1) (the mass ratio of sodium alginate and konjac gum is 1:1), mix and stir, and adjust the content of The amount of water is 45%, the stirring speed is 200r / min, the stirring time is 15min, and stand for 24 hours;

[0038] (3) Extrusion: Extrusion is carried out by twin-screw extrusion process. The process conveying section is 35°C, the melting section is 120°C, and the forming section is 110°C. The length of the knife speed is controlled at 3cm, and the moisture content of the extruded plant tissue protein is 35%;

[0039] (4) Wet cooling: step (3) the extruded plant tissue protein is cooled to 70°C at a humidity of 35%;

[0040] (5) Gradient dehydration with de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com