Method for improving stress resistance of chip solid electrolytic capacitor

A solid electrolyte and capacitor technology, applied in the direction of electrolytic capacitors, capacitors, capacitor electrodes, etc., can solve the problems of stress concentration, but not solve the problems of cathode manganese dioxide layer density and poor uniformity, so as to eliminate stress concentration and eliminate local weakness. Phenomenon, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

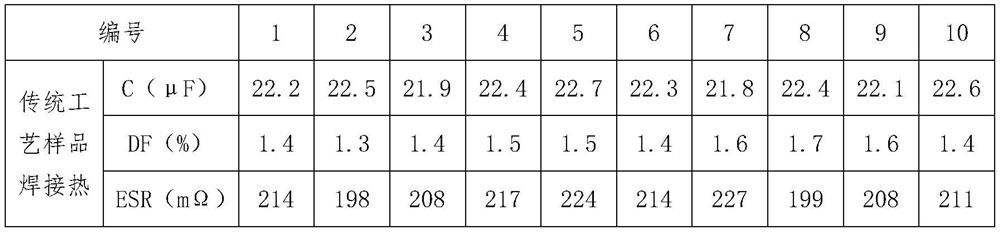

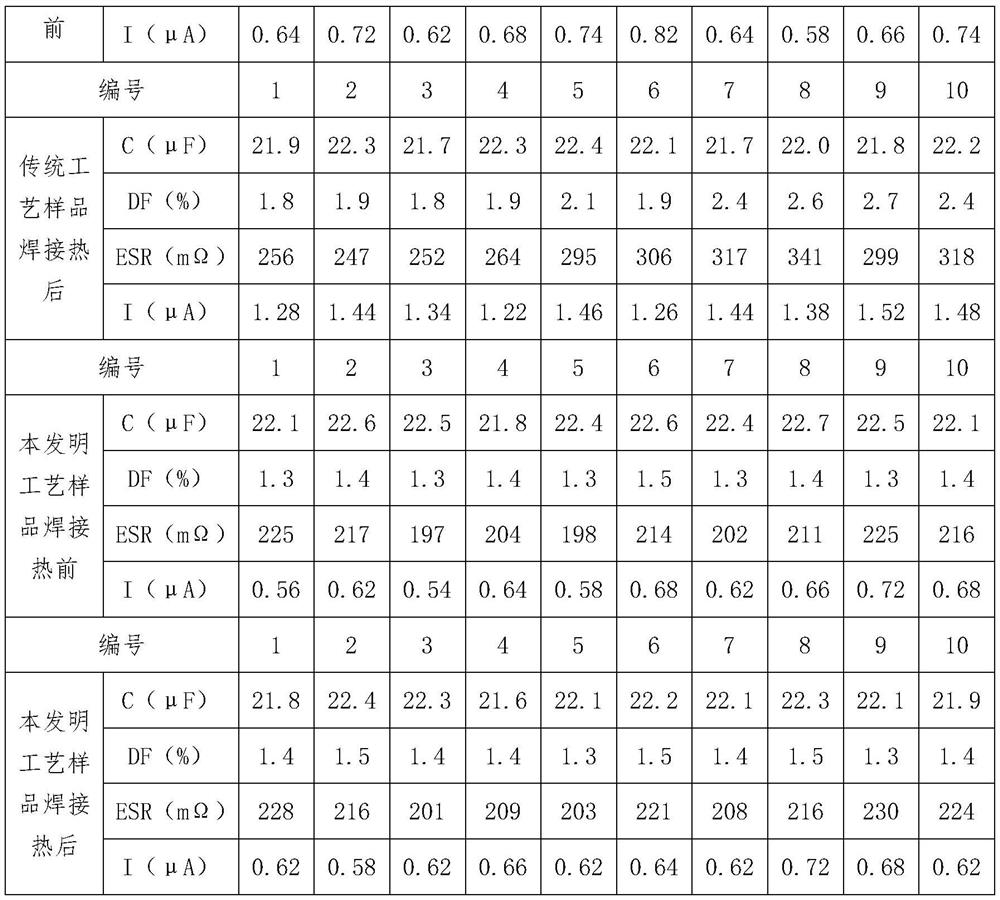

Embodiment 1

[0030] Methods to improve the stress resistance of chip solid electrolytic capacitors:

[0031] 1. The design of the anode: chamfering the edges in the height direction of the rectangular anode tantalum block, and turning the right-angled edges into arc shapes.

[0032] 2. Cathodic coating strengthening:

[0033] (1) The chamfered anode tantalum block is subjected to high-temperature vacuum sintering, and then electrochemically treated to form an amorphous dielectric oxide film on the surface of the anode tantalum block;

[0034] (2) immerse the anode tantalum block forming the dielectric layer in the manganese nitrate solution, and process through multiple dipping and decomposition to form the inner layer of the cathode manganese dioxide layer;

[0035] (3) Immerse the anode tantalum block forming the inner layer of the cathode manganese dioxide layer in the manganese nitrate mixed solution for 6 minutes to 12 minutes, take out and dip the excess manganese nitrate mixed solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com