A molten salt constant temperature system and its application method

A constant temperature system and molten salt technology, applied in the field of heat treatment, can solve the problems of large constant temperature system equipment, poor constant temperature accuracy, complex structure, etc., and achieve the effect of ensuring good operation, reducing the temperature difference between the upper and lower walls, and reducing water level fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

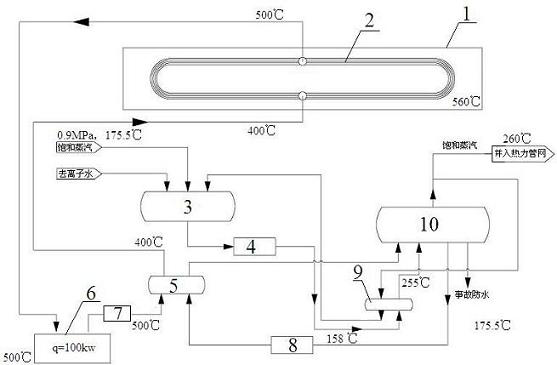

[0030] This embodiment provides a molten salt constant temperature system, including a molten salt tank 6, a constant temperature working salt tank 1 and a water heat exchange system, the constant temperature working salt tank 1 is provided with a salt-salt heat exchanger 2, and the molten salt The outlet of the tank 6 communicates with the water heat exchange system, the outlet of the water heat exchange system communicates with the salt-salt heat exchanger 2 , and the outlet of the salt-salt heat exchanger 2 communicates with the molten salt tank 6 .

[0031] When the system is working, the temperature of the molten salt in the working salt tank is 560°C. Since high-temperature products (generally above 900°C) directly enter the constant temperature working salt tank 1, the temperature of the molten salt in the working salt tank rises rapidly. The salt-salt heat exchanger 2 is arranged. Low-temperature molten salt (cold salt for short) flows in the heat exchange tube, and 560...

Embodiment 2

[0034] On the basis of Example 1, this embodiment provides a molten salt constant temperature system. The water heat exchange system includes an evaporator 5, a water supply device and a steam drum 10, and the evaporator 5 and the water supply device are connected with each other. The steam drum 10 is connected, and a steam-water circulating pump 8 is installed between the evaporator 5 and the steam drum 10, and the outlet of the steam drum 10 is connected to a heat pipe network;

[0035] The outlet of the molten salt tank 6, the evaporator 5 and the inlet of the salt-salt heat exchanger 2 are sequentially connected through heat tracing pipes.

[0036] Hot salt (about 500°C) at the outlet of salt-salt heat exchanger 2 enters the molten salt tank 6, and is sent to the evaporator 5 through the molten salt pump 7 in the molten salt tank 6 for heat exchange, and the cold salt (about 400°C) at the outlet returns to the salt Salt heat exchanger 2. The water in the steam drum 10 is ...

Embodiment 3

[0038] On the basis of Embodiment 1 or 2, this embodiment provides a molten salt constant temperature system, which also includes a control system, a temperature sensor 1 is provided in the constant temperature working salt tank 1, and the molten salt tank 6 is exchanged with water A molten salt pump 7 is installed on the pipeline between the thermal systems, and the temperature sensor 1, the molten salt pump 7 and the water heat exchange system are all connected to the control system with electrical signals.

[0039] Input various parameters (such as wire quality and temperature, molten salt quality and temperature in constant temperature working salt tank 1, cold salt temperature, outlet hot salt temperature, medium specific heat capacity, density, etc.), and calculate the cold salt temperature through the control system according to the heat exchange formula Mass flow, this part belongs to the prior art. The control system monitors the value of the temperature sensor 1 in r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com