Cement pavement slab staggering treatment structure and construction method

A cement pavement and structure treatment technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of poor bonding and compounding effect, shedding or damage of pouring materials, and insignificant bonding effect enhancement effect, etc., to achieve enhanced composite bonding Strength, delaying cracks and fractures, and alleviating the effects of bagging diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

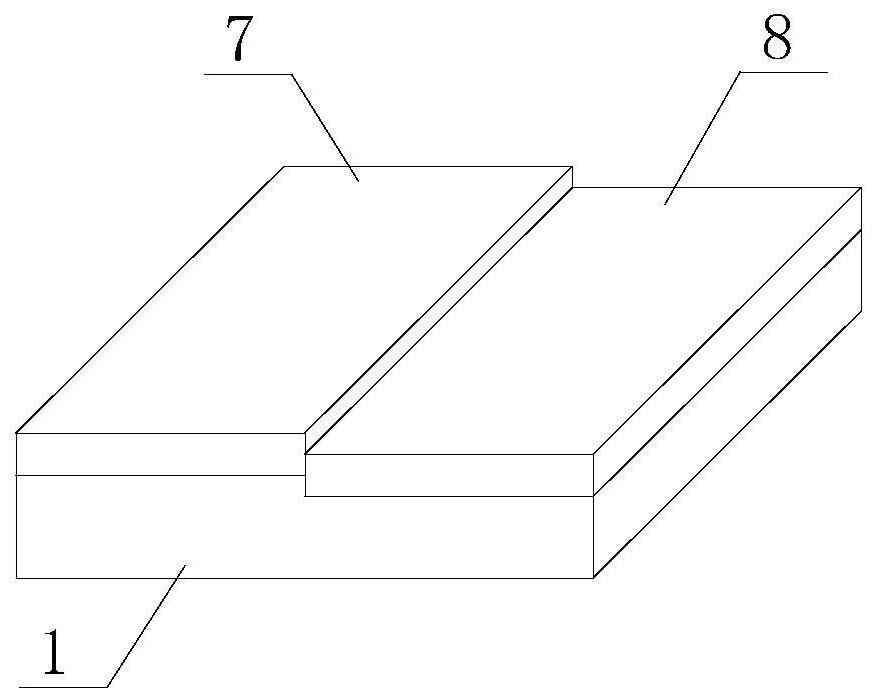

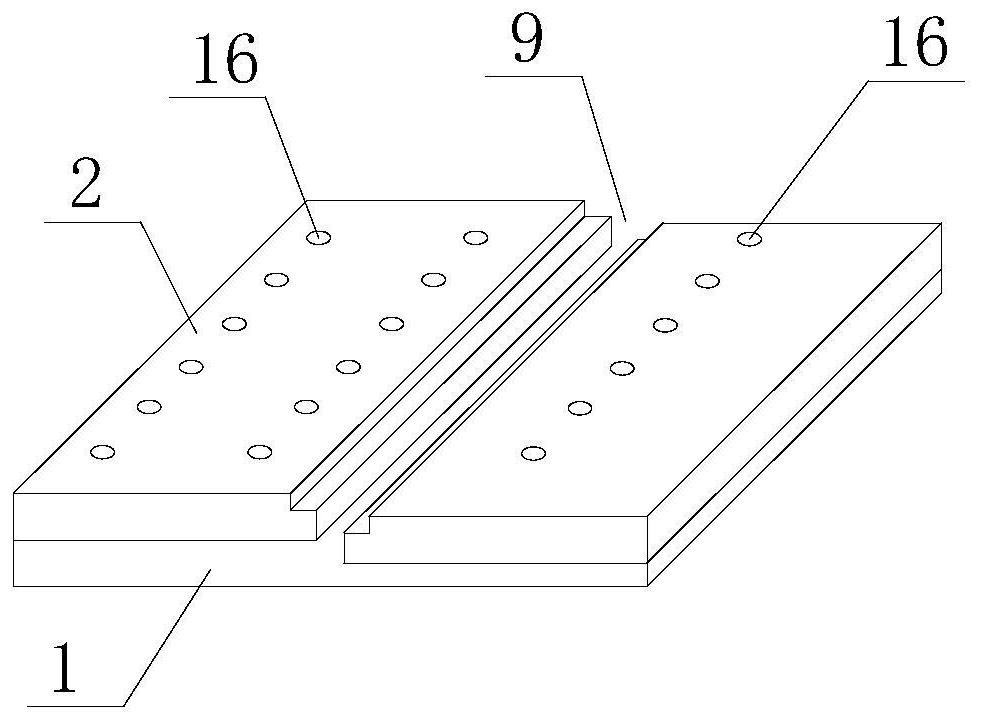

[0058] In this embodiment, the wrong platform treatment structure includes the base layer 1 and the old surface layer 2; the wrong platform treatment structure also includes a repair layer 3, a wrong platform connector 4, a leveling layer 5 and a new surface layer 6; the old surface layer 2 is set on the base layer 1, the old surface layer 2 includes the in-situ plate 7 and the sinking plate 8, and the repair layer 3 is set in the base layer 1.

[0059] In this embodiment, a T-shaped slot 9 is opened along the boundary gap between the in-situ plate 7 and the sinking plate 8 ; and an installation hole 16 for installing a fixing rod 15 is opened on the old surface layer 2 .

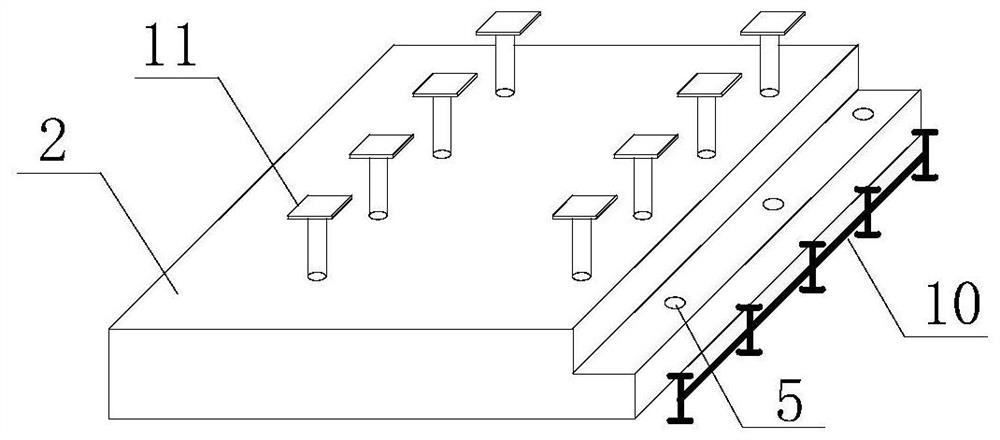

[0060] In this embodiment, the repair layer 3 and the staggered connector 4 are provided with a knotting device 10; the leveling layer 5 is provided on the upper surface of the sinking plate 8; the new surface layer 6 is provided on the in-situ plate 7 And on the leveling layer 5; on the in-situ plate 7 and...

Embodiment 2

[0076] In this embodiment, the wrong platform treatment structure includes the base layer 1 and the old surface layer 2; the wrong platform treatment structure also includes a repair layer 3, a wrong platform connector 4, a leveling layer 5 and a new surface layer 6; the old surface layer 2 is arranged on the base layer 1, and the old surface layer 2 includes an in-situ plate 7 and a sinking plate 8.

[0077] In this embodiment, a T-shaped slot 9 is opened along the boundary gap between the in-situ plate 7 and the sinking plate 8 ; and an installation hole 16 for installing a fixing rod 15 is opened on the old surface layer 2 .

[0078] In this embodiment, the repair layer 3 and the staggered connector 4 are provided with a knotting device 10; the leveling layer 5 is provided on the upper surface of the sinking plate 8; the new surface layer 6 is provided on the in-situ plate 7 And on the leveling layer 5; on the in-situ plate 7 and the leveling layer 5, an anti-wrapping devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com