Flue gas purification system for aluminum purification furnace

A flue gas purification system and technology for furnaces, which are applied to furnaces, furnace components, and energy efficiency improvement, can solve problems such as unfavorable environmental protection, pollute the air, and affect normal life, and achieve the effect of fully and thoroughly flue gas purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

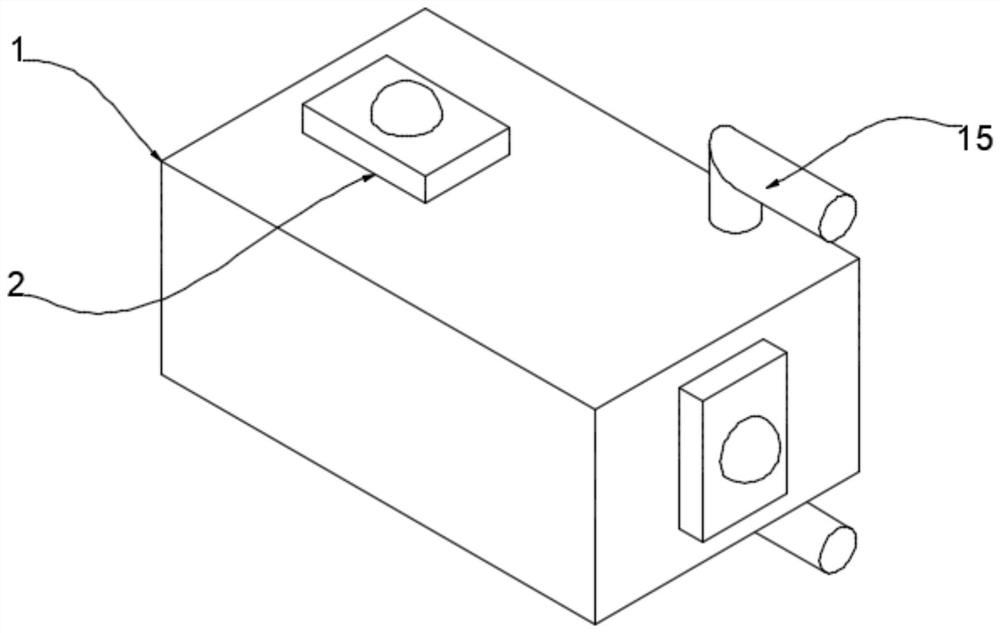

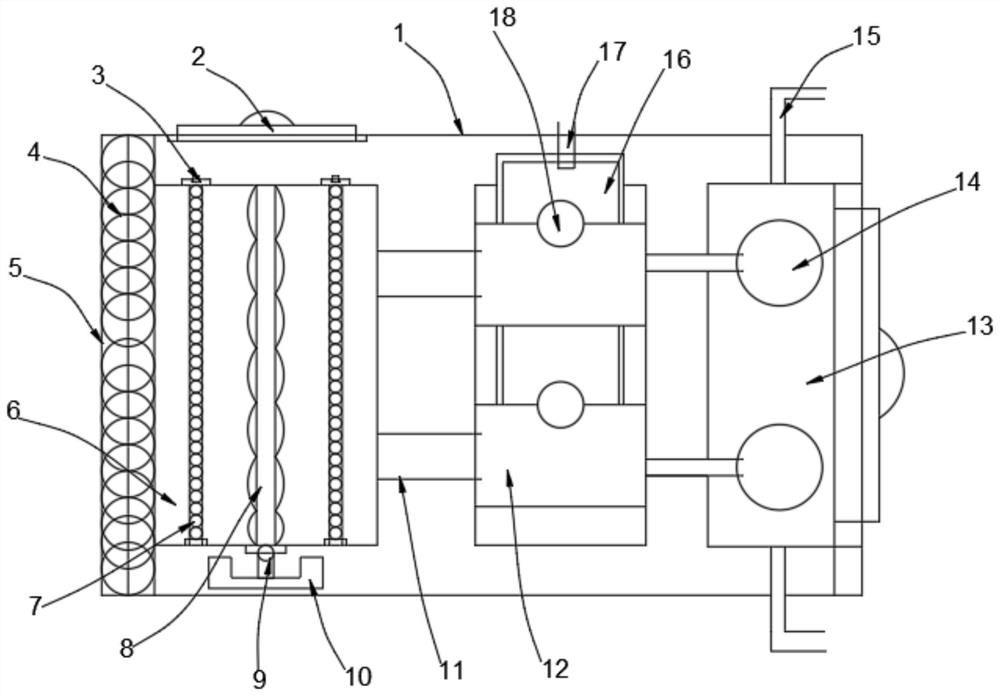

[0023] see Figures 1 to 4 :

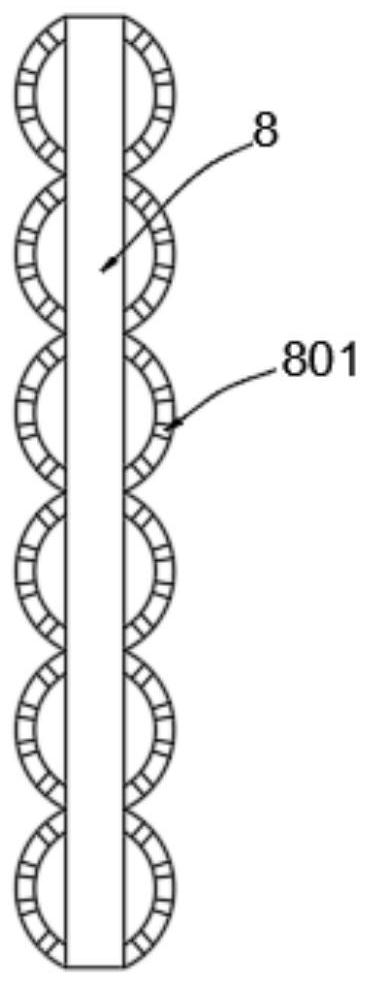

[0024] This embodiment provides a flue gas purification system for an aluminum purification furnace, including a housing 1, an air inlet 5, a precipitation chamber 6, a reaction chamber 12, and a cooling chamber 13. The front end of the housing 1 is fixedly provided with an air inlet 5, and the air inlet 5. A filter screen 4 is fixedly installed in the middle, and the inner side of the air inlet 5 is fixedly connected with a sedimentation chamber 6. The inner middle of the sedimentation chamber 6 is rotated and installed with a water column 8 . Rod 7, the top of colloid rod 7 is fixedly connected with fastening nut 3, the bottom end of water column 8 is fixedly connected with motor 10 through transmission shaft 9, the top of sedimentation chamber 6 is fixedly provided with end cover 2, and sedimentation chamber 6 is fixedly connected with conveying pipe 11. The reaction chamber 12 is provided with a transmission ball 18 rotating inside the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com