Casting exhaust gas acid mist purification tower

A purification tower and acid mist technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problem that the spray liquid cannot be sprayed uniformly, reduce the purification effect of acid mist purification tower, acid mist and spray liquid Insufficient contact and other problems, to achieve the effect of wide spray coverage, enhanced contact, and less leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

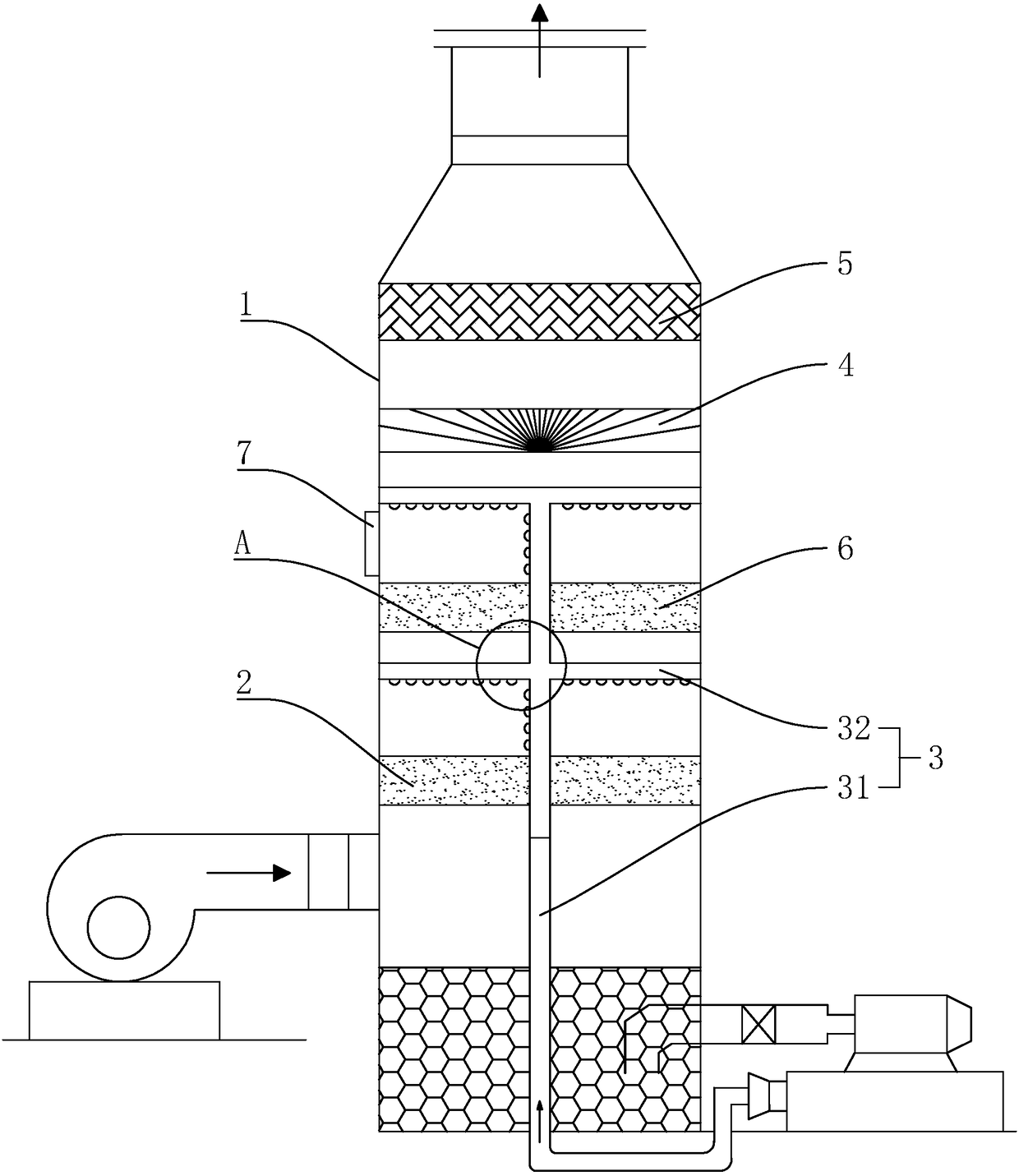

[0025] A casting waste gas acid mist purification tower provided in this embodiment has a structure such as Figure 1 to Figure 3 As shown, including the tower body 1, a transparent inspection window 7 is provided on the outside of the tower body 1, and the interior of the tower body 1 is sequentially provided with a dehydration layer 5, a swirl plate 4, a spray device 3 and a packing layer 2 from top to bottom. .

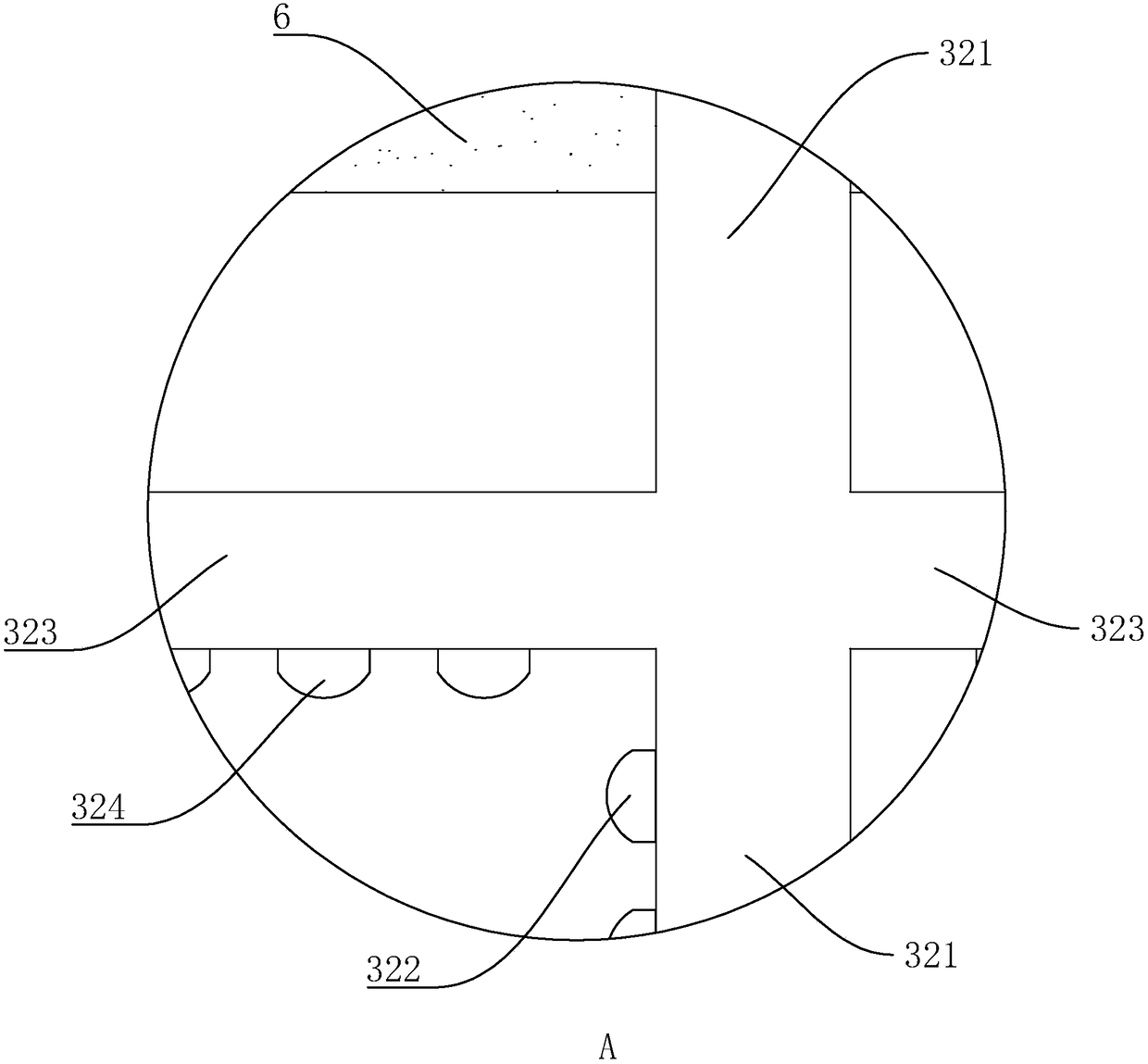

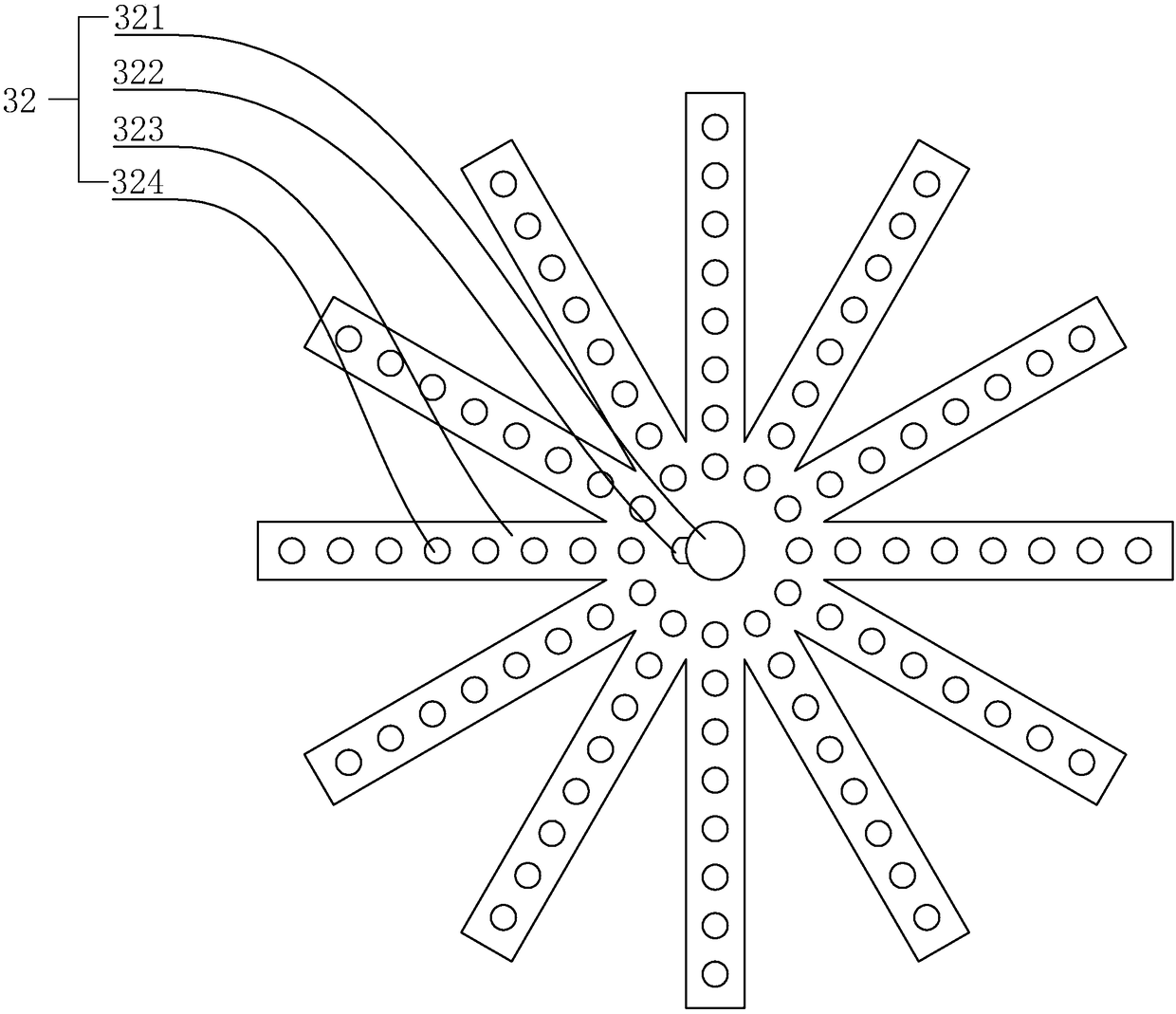

[0026] The spray device 3 includes a liquid inlet pipe 31 arranged at the lower end of the tower body 1 and a spray unit 32 connected to the upper end of the liquid inlet pipe 31, and the liquid inlet pipe 31 is arranged coaxially with the tower body 1; the swirl plate 4 and the packing layer 2 are provided with a number of filler reinforcement layers 6, the number of filler reinforcement layers 6 can be adjusted according to the actual situation, a spray unit 32 is arranged between the swirl plate 4 and the uppermost filler reinforcement layer 6, and the filler la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com