Method for extracting peony seed oil through ultrasonic-assisted biological enzymolysis

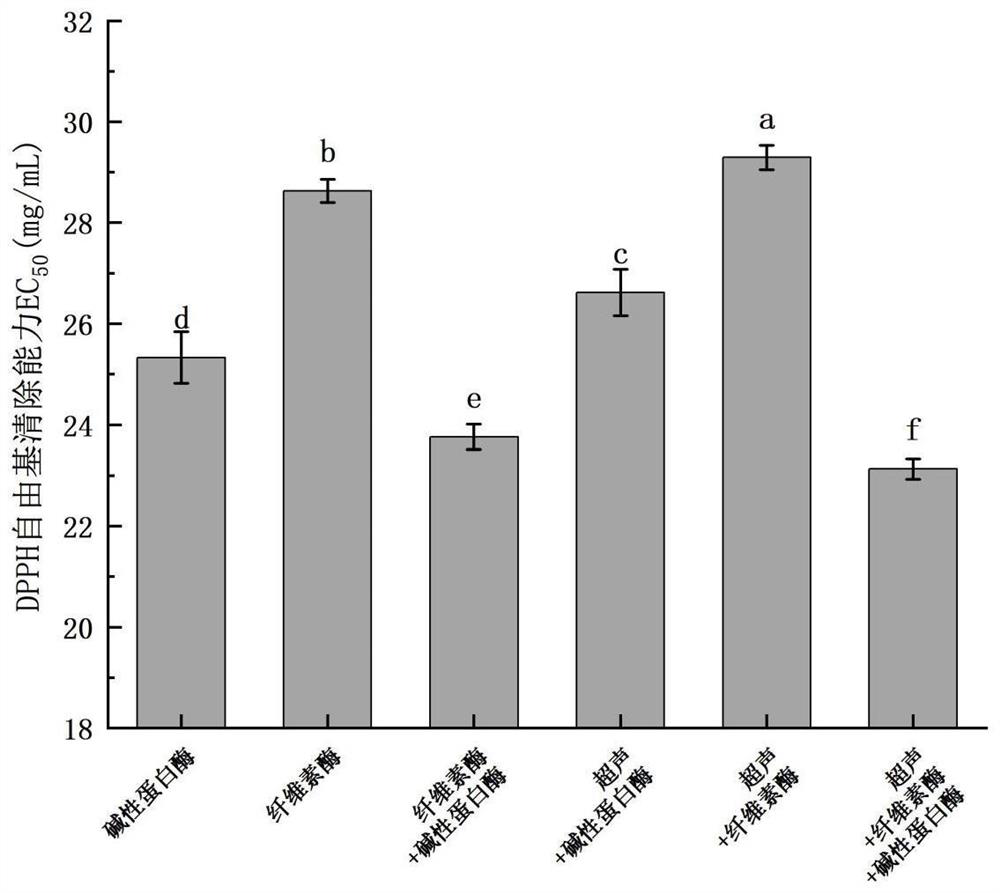

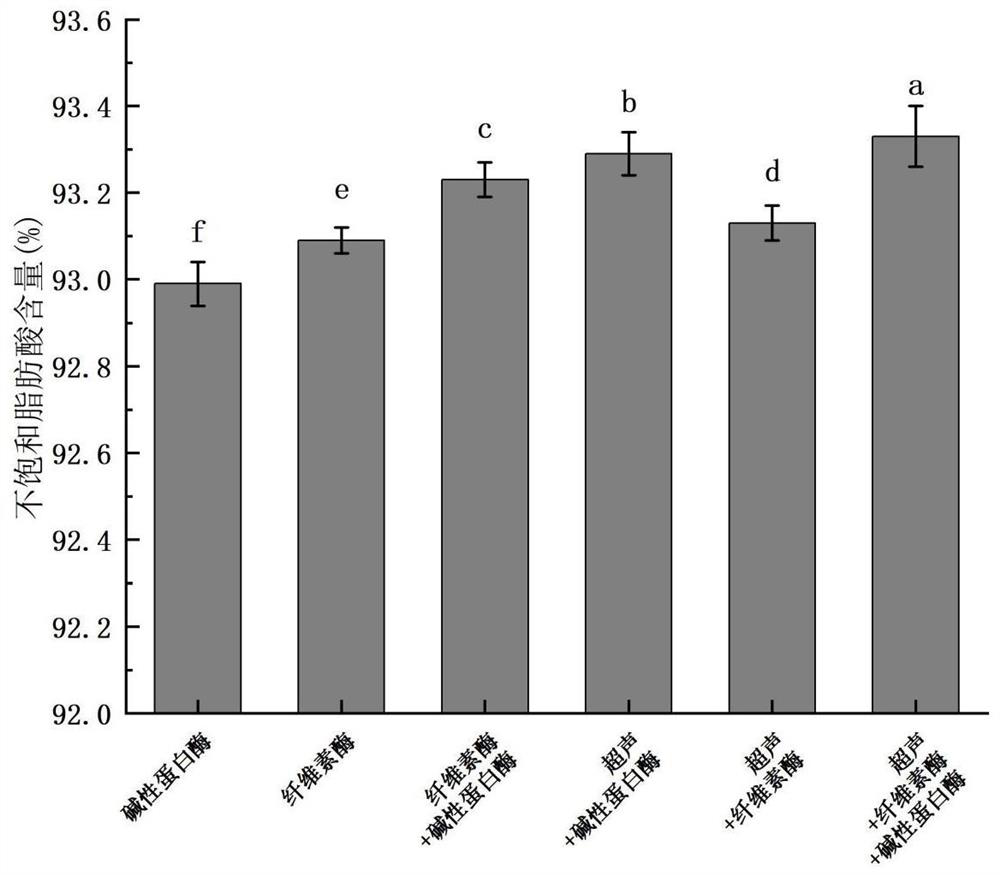

A peony seed oil, ultrasonic-assisted technology, applied in the direction of fat production, fat oil/fat production, fat oil/fat refining, etc., can solve the problem that the oil cannot completely flow out, and achieve strong anti-oxidation, pure flavor, and unsaturated fatty acid content high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

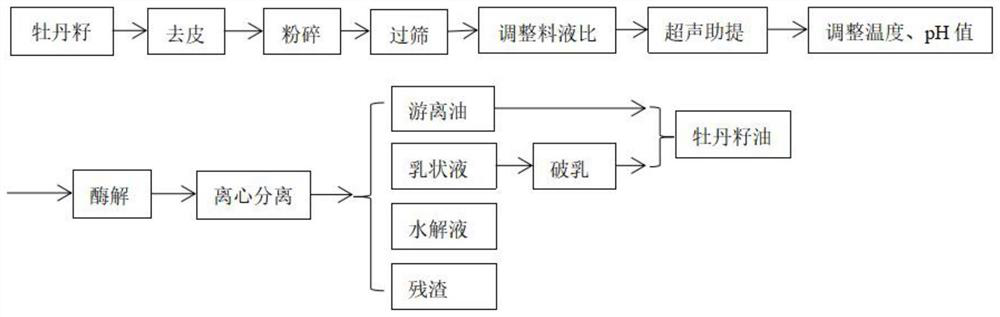

Method used

Image

Examples

Embodiment example 1

[0024] Pulverize peony seeds in a pulverizer, pass through a 60-mesh sieve to obtain the undersize material for use; mix the undersize material with deionized water in a ratio of 1:5 and stir evenly to form a semi-solid mixed solution, and mix the mixed solution Under the conditions of ultrasonic power of 300W and ultrasonic temperature of 45°C, perform ultrasonic treatment for 55 minutes; adjust the pH value of the mixture after ultrasonic treatment to 5.0, add 0.5% (v / w) cellulase for enzymatic hydrolysis for 1 hour, and inactivate the enzyme at 90°C 10min, then adjust the pH of the mixed solution to 9.0, add 1.5% (v / w) alkaline protease protex 6L for enzymolysis for 2h, and inactivate the enzyme at 90°C for 10min; cool the enzymolyzate after inactivation to 4°C and perform high-speed centrifugation , to obtain free oil, emulsion, hydrolyzate, and residue; the emulsion was frozen and demulsified at -20°C for 24 hours, and after thawing at 40°C, it was centrifuged at 10,000 g ...

Embodiment example 2

[0026] Pulverize peony seeds in a pulverizer, pass through a 60-mesh sieve to obtain the undersize material for use; mix the undersize material with deionized water in a ratio of 1:5 and stir evenly to form a semi-solid mixed solution, and mix the mixed solution Under the conditions of ultrasonic power of 400W and ultrasonic temperature of 40°C, perform ultrasonic treatment for 45 minutes; adjust the pH value of the mixture after ultrasonic treatment to 5.0, add 0.5% (v / w) cellulase for enzymatic hydrolysis for 1 hour, and inactivate the enzyme at 90°C 10min, then adjust the pH of the mixed solution to 9.0, add 1.5% (v / w) alkaline protease protex 6L for enzymolysis for 2h, and inactivate the enzyme at 90°C for 10min; cool the enzymolyzate after inactivation to 4°C and perform high-speed centrifugation , to obtain free oil, emulsion, hydrolyzate, and residue; the emulsion was frozen and demulsified at -20°C for 24 hours, and after thawing at 40°C, it was centrifuged at 10,000 g ...

Embodiment example 3

[0028] Pulverize peony seeds in a pulverizer, pass through a 60-mesh sieve to obtain the undersize material for use; mix the undersize material with deionized water in a ratio of 1:5 and stir evenly to form a semi-solid mixed solution, and mix the mixed solution Under the conditions of ultrasonic power of 500W and ultrasonic temperature of 30°C, perform ultrasonic treatment for 35 minutes; adjust the pH value of the mixture after ultrasonic treatment to 5.0, add 0.5% (v / w) cellulase for enzymatic hydrolysis for 1 hour, and inactivate the enzyme at 90°C 10min, then adjust the pH of the mixed solution to 9.0, add 1.5% (v / w) alkaline protease protex 6L for enzymolysis for 2h, and inactivate the enzyme at 90°C for 10min; cool the enzymolyzate after inactivation to 4°C and perform high-speed centrifugation , to obtain free oil, emulsion, hydrolyzate, and residue; the emulsion was frozen and demulsified at -20°C for 24 hours, and after thawing at 40°C, it was centrifuged at 10,000 g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com