Thermotropic liquid crystal block polyarylate as well as preparation and application thereof

A technology of thermotropic liquid crystal and polyarylate, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of high equipment requirements, inability to balance the operation method and product performance at the same time, and cumbersome reaction steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

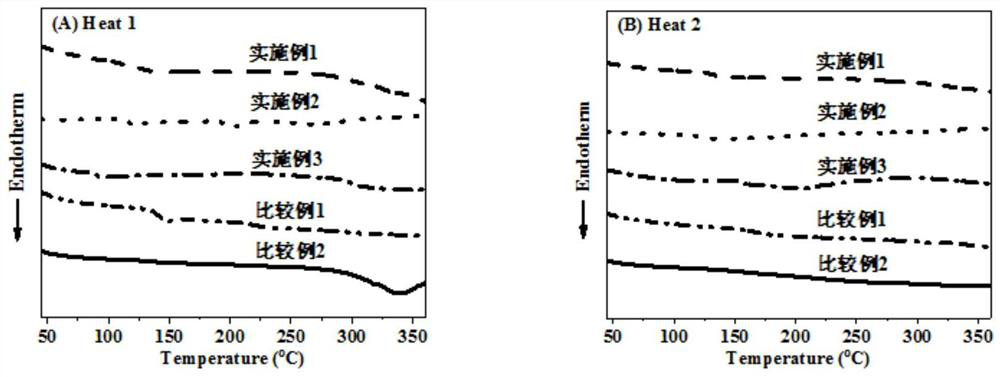

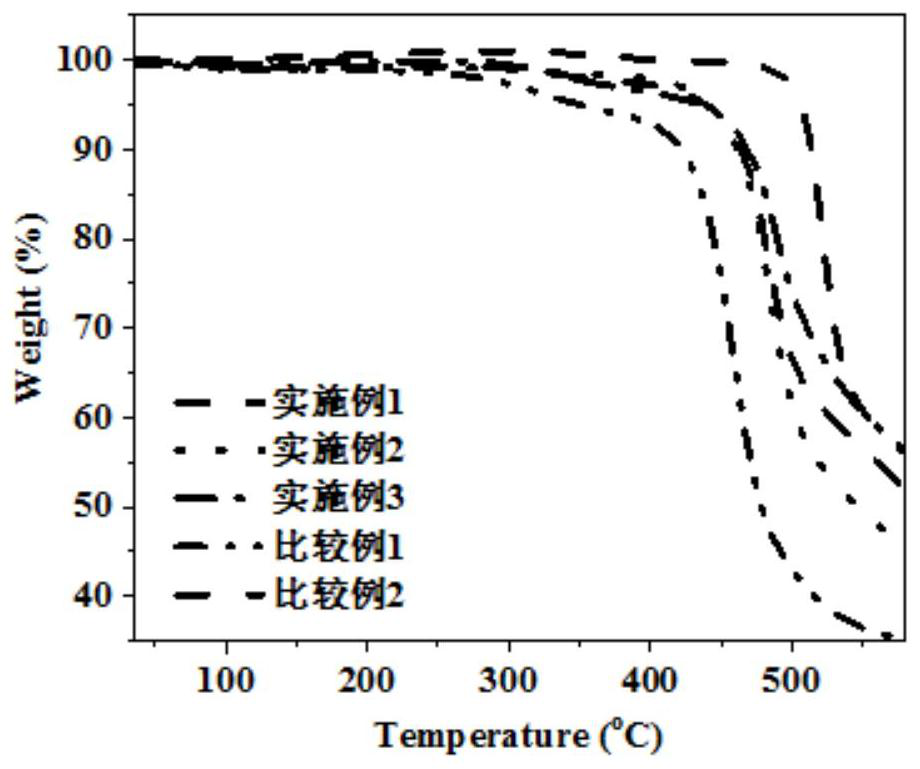

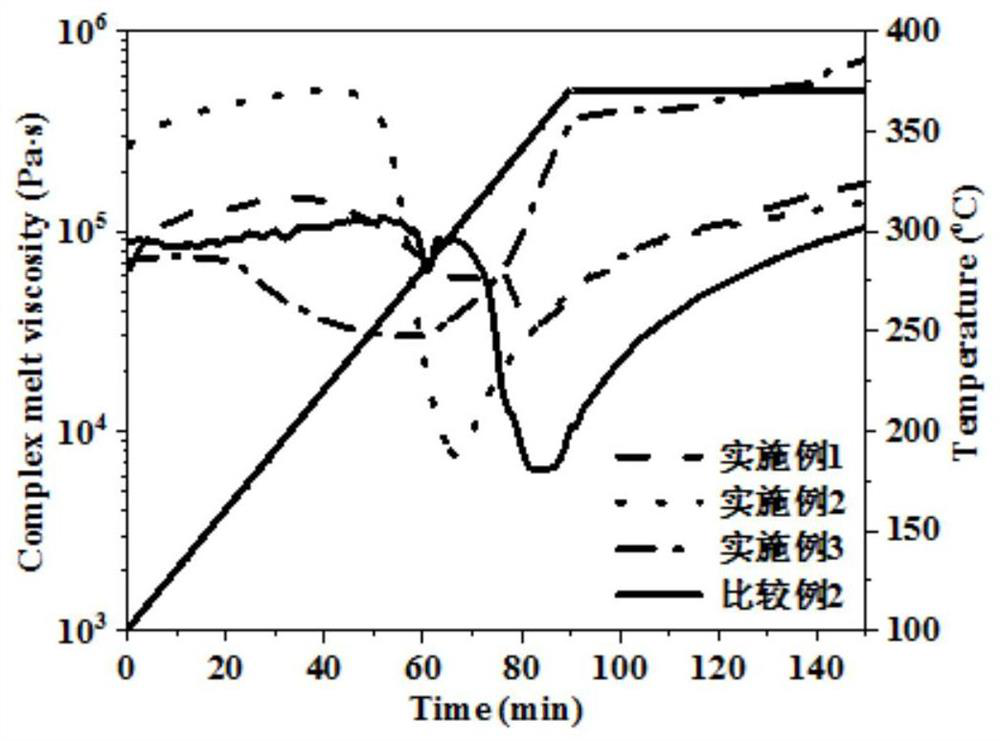

Embodiment 1

[0042]This example prepares thermotropic liquid crystal block polyarylate, the method is as follows: add 82.878g of p-hydroxybenzoic acid (I), 42.844g of 4,4'-dihydroxybenzophenone (II-I) into a 250ml three-neck round bottom flask respectively ), 16.613g terephthalic acid (Ⅲ), 21.619g 2,6-naphthalene dicarboxylic acid (Ⅳ). Then 173.553 g of acetic anhydride and 0.164 g of potassium acetate were added. The flask is equipped with a sealed metal paddle stirrer and a mechanical stirring device to control the stirring rate of the reaction mixture; one side is equipped with a nitrogen inlet pipe and a control valve to control the nitrogen flow rate according to the reaction process; the other side is equipped with an insulated distillation head. The nitrogen atmosphere was maintained, and the reaction mixture was kept in a quicksand bath at 150° C. for 35 minutes to carry out the acetylation reaction. Then the temperature was raised to 290°C at a rate of 0.6°C / min and kept warm. At...

Embodiment 2

[0045] This example prepares thermotropic liquid crystal block polyarylate, the method is as follows: add 41.439g of p-hydroxybenzoic acid (I) and 101.105g of 4,4'-dihydroxydiphenyl ether (II-II) into a 250ml three-neck round bottom flask respectively , 29.903g of terephthalic acid (III), 4.324g of 2,6-naphthalene dicarboxylic acid (IV). Then 132.717 g of acetic anhydride and 0.884 g of potassium acetate were added. The flask is equipped with a sealed metal paddle stirrer and a mechanical stirring device to control the stirring rate of the reaction mixture; one side is equipped with a nitrogen inlet pipe and a control valve to control the nitrogen flow rate according to the reaction process; the other side is equipped with an insulated distillation head. The nitrogen atmosphere was maintained, and the acetylation reaction of the reaction mixture was started at 130° C. in a quicksand bath, and the reaction time was 55 minutes. Then the temperature was raised to 310°C at a rate...

Embodiment 3

[0050] This example prepares thermotropic liquid crystal block polyarylate, the method is as follows: add 69.065g of hydroxybenzoic acid (I), 60.069g of bisphenol F (II-III), and 24.920g of terephthalic acid respectively in a 250ml three-neck round bottom flask (Ⅲ), 10.810 g of 2,6-naphthalene dicarboxylic acid (Ⅳ). Then 142.926 g of acetic anhydride and 0.330 g of potassium acetate were added. At the same time, the flask is equipped with a sealed metal paddle stirrer and related mechanical stirring devices to control the stirring rate of the reaction mixture; one side of the flask is equipped with a nitrogen inlet pipe and a control valve to control the nitrogen flow rate according to the reaction process; the other side is equipped with a thermal insulation distillation head . Maintaining a nitrogen atmosphere, the reaction mixture was acetylated in a quicksand bath for 50 min at a temperature of 140°C. Then, the temperature was raised to 300° C. at a rate of 1.1° C. / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com