Water plant sludge dewatering automatic control system

An automatic control system, sludge dewatering technology, applied in the general control system, control/regulation system, water/sludge/sewage treatment, etc., can solve the inconvenience of operation, low control efficiency and operation efficiency, control effect and function Unevenness and other problems, to achieve high-efficiency control, ensure operating efficiency, and save time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

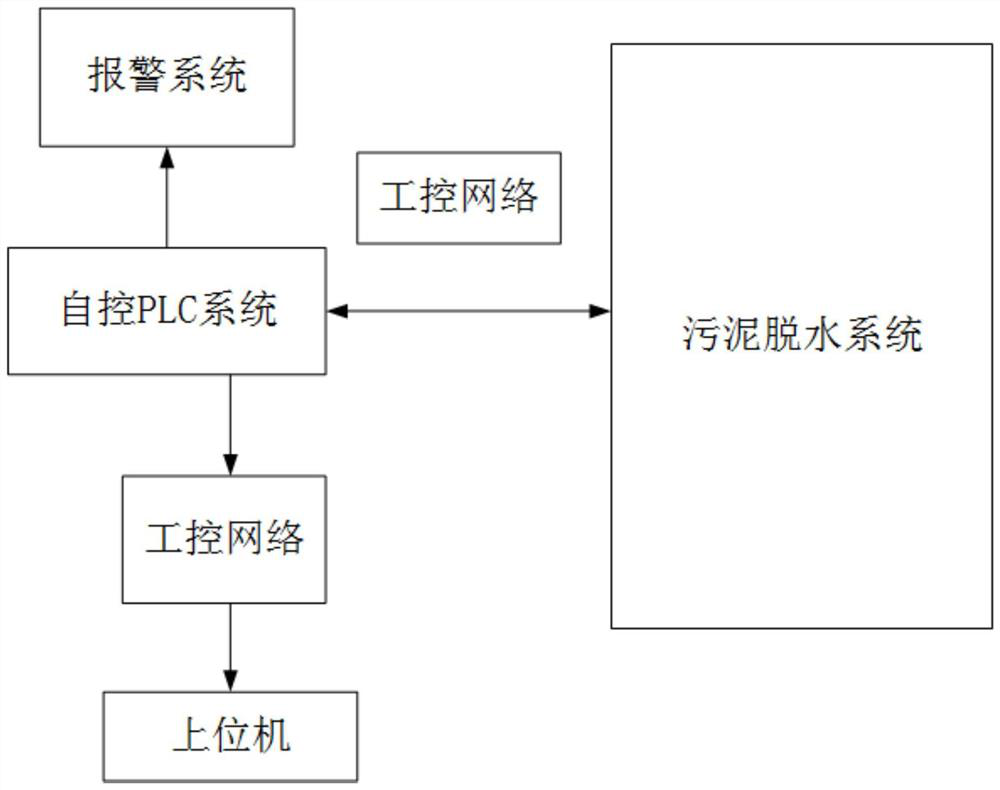

[0033] The invention relates to an automatic control system for sludge dehydration in a waterworks, comprising an automatic control PLC system, a sludge dewatering system, an industrial control network, a host computer and an alarm system.

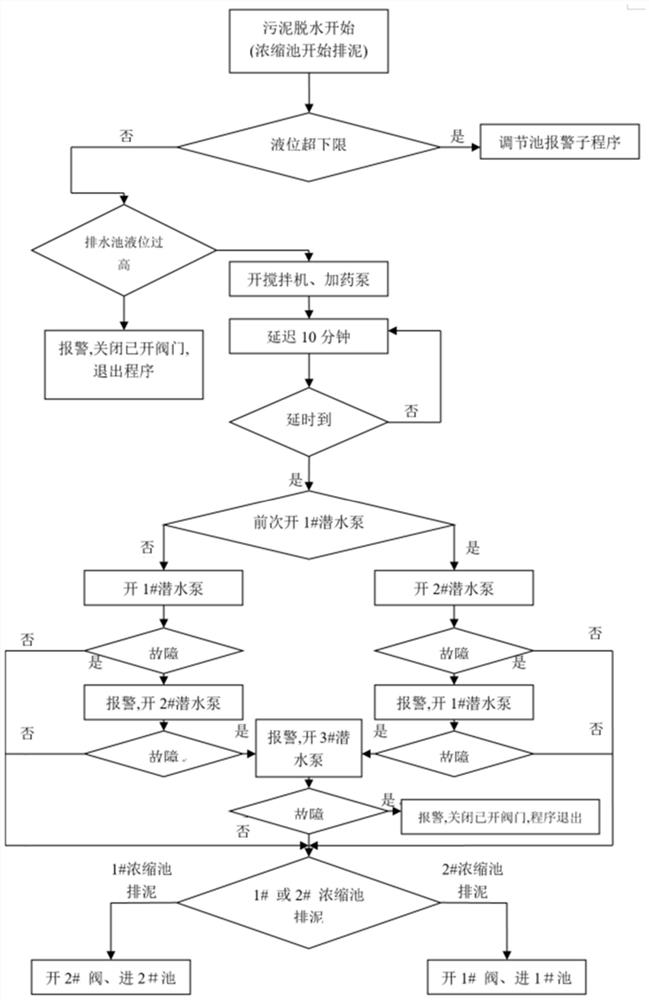

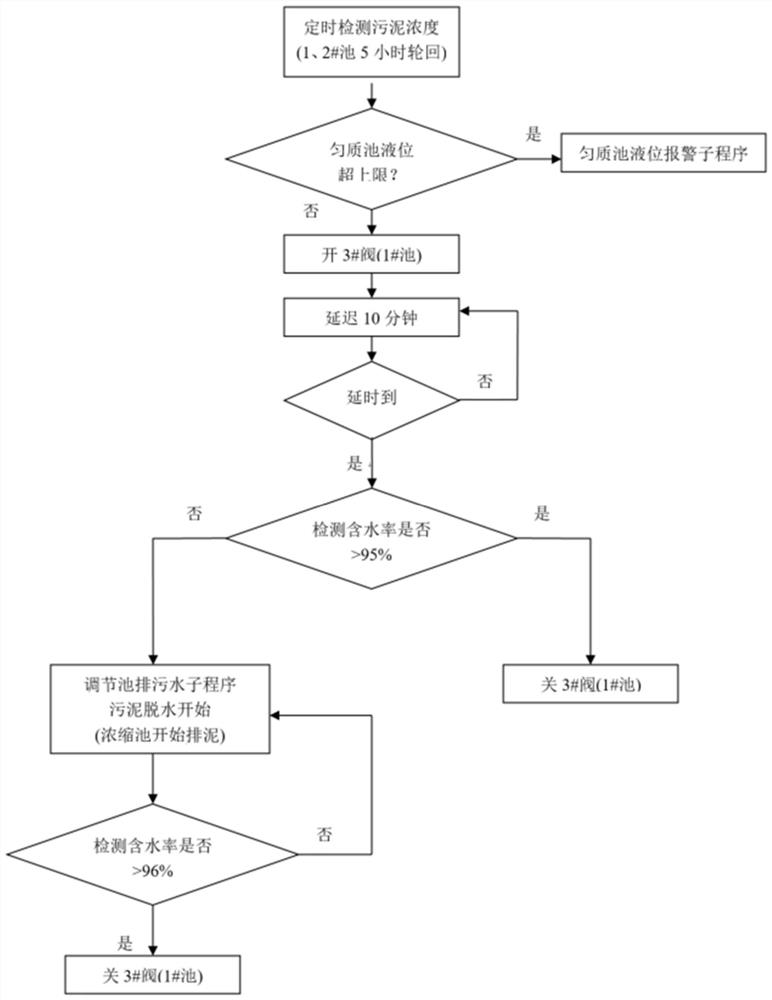

[0034] The dehydration process is the core process of the whole sludge dewatering treatment. The sludge dewatering system includes a regulating tank, a thickening tank, a thickening machine, a filter press equipment group and a liquid distribution system. The sewage in the regulating tank is pumped into the thickening tank through a submersible pump. There is a concentration meter for measuring the concentration of sludge. The filter press equipment group separates the mud and water in the sludge under the action of the liquid distribution system, and the dry mud is produced through the extrusion of the filter cloth. The filter press equipment group includes sewage. Mud pumps, flushing pumps, submersible pumps, coagulators, filter presses,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com