Modular integration system for treating medicine intermediate production wastewater, and working method thereof

A technology for producing wastewater and an integrated system, which is applied in the fields of environmental management and resource utilization, can solve the problems such as the inability to achieve efficient removal of high-concentration organic matter, and achieve the effects of improving equipment utilization, reducing operating costs, and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

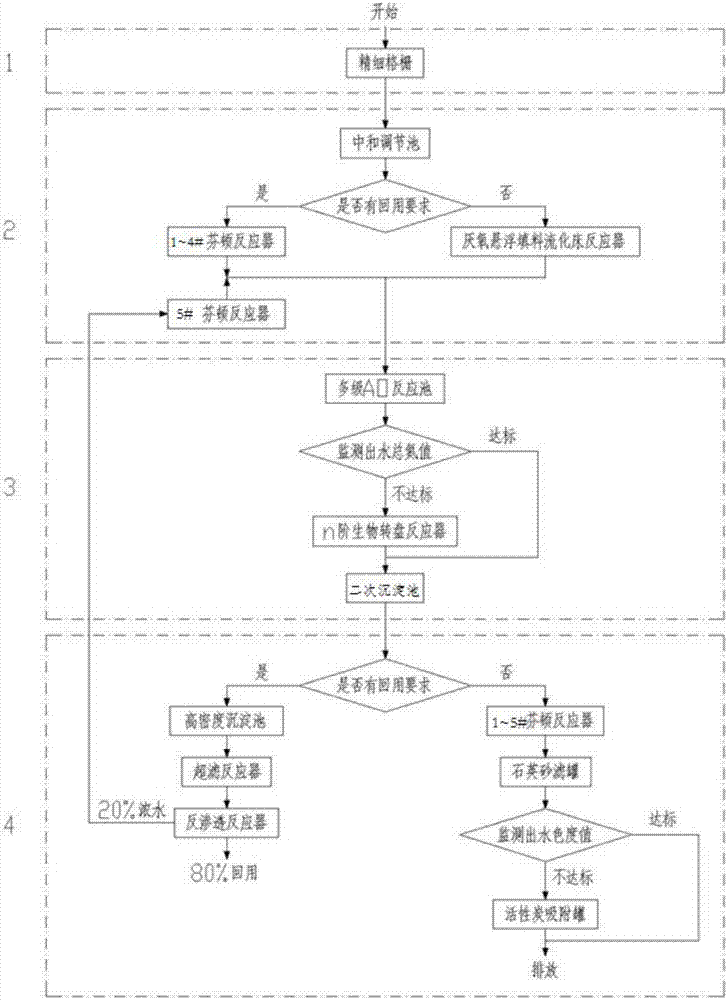

Method used

Image

Examples

Embodiment 1

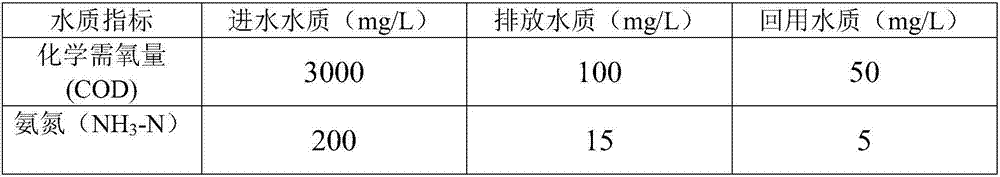

[0039] A pharmaceutical company mainly produces a variety of pharmaceutical intermediates, including L-glutamine, zinc acetate and red yeast rice. The total amount of discharged water is 1000t / d, the influent COD is about 3000mg / L, and the ammonia nitrogen is about 200mg / L. The plant mainly produces L-glutamine, and there is a requirement for reuse of water. When L-glutamine production is stopped or equipment is overhauled, there is no requirement for reuse. The water quality after treatment can meet the discharge requirements and can be discharged outside. See the table below for the water quality of the incoming and outgoing water.

[0040]

Embodiment 2

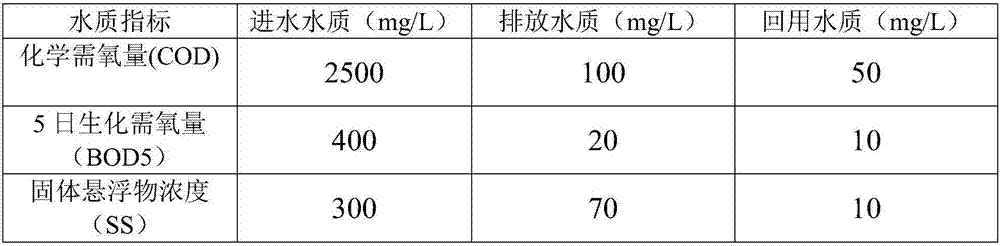

[0042] A pharmaceutical company mainly produces a variety of pharmaceutical intermediates, including nitrochlorobenzene, vanillin and p-aminophenol. The discharged water is 2500t / d of nitrochlorobenzene, 500t / d of vanillin and 1500t / d of p-aminophenol, and 500t / d of other domestic and production wastewater, totaling 5000t / d. The sewage outlet of the plant is set in a seasonal river. According to the requirements of the local environmental protection bureau, drainage can be carried out from March to November every year, and discharge is not allowed in the dry season of December, January and February. Therefore, there are recycling requirements in December, January and February, and all wastewater is reused without being discharged outside. There is no recycling requirement in other months, which reduces the cost of wastewater treatment. The content of ammonia nitrogen in this water is relatively high, so the second-level biochemical module and the fourth-level biological turnta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com