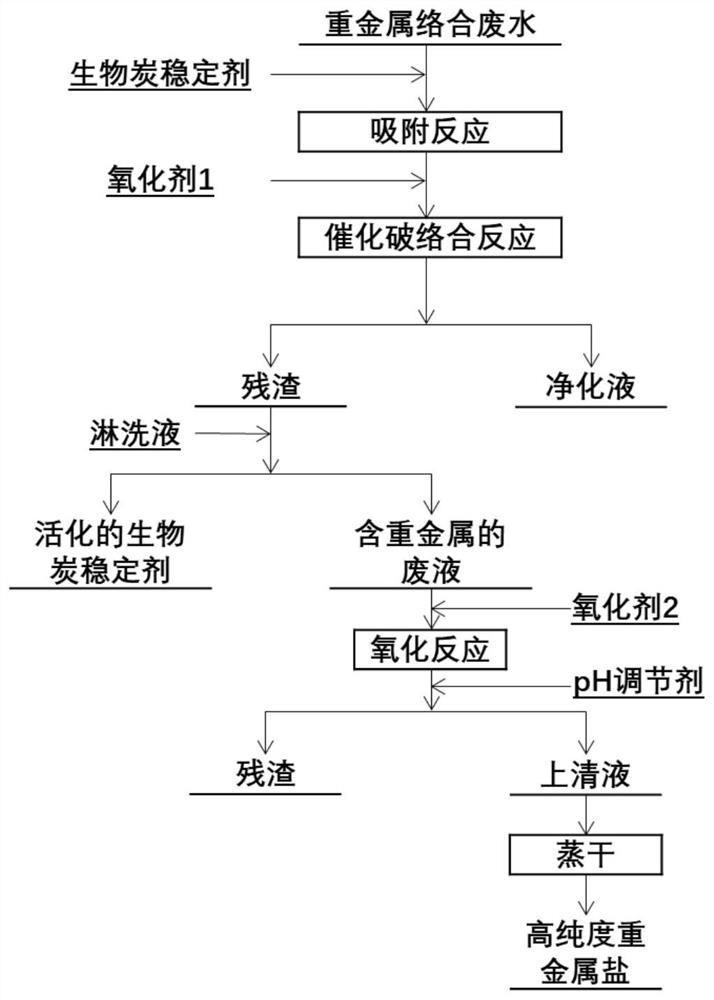

Heavy metal complex wastewater treatment and recycling process based on iron-based biochar

A wastewater treatment and treatment process technology, applied in water/sewage treatment, adsorption water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of difficult resource utilization and low oxidation efficiency, and achieve high reuse rate and interception The effect of high efficiency and low oxidant utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

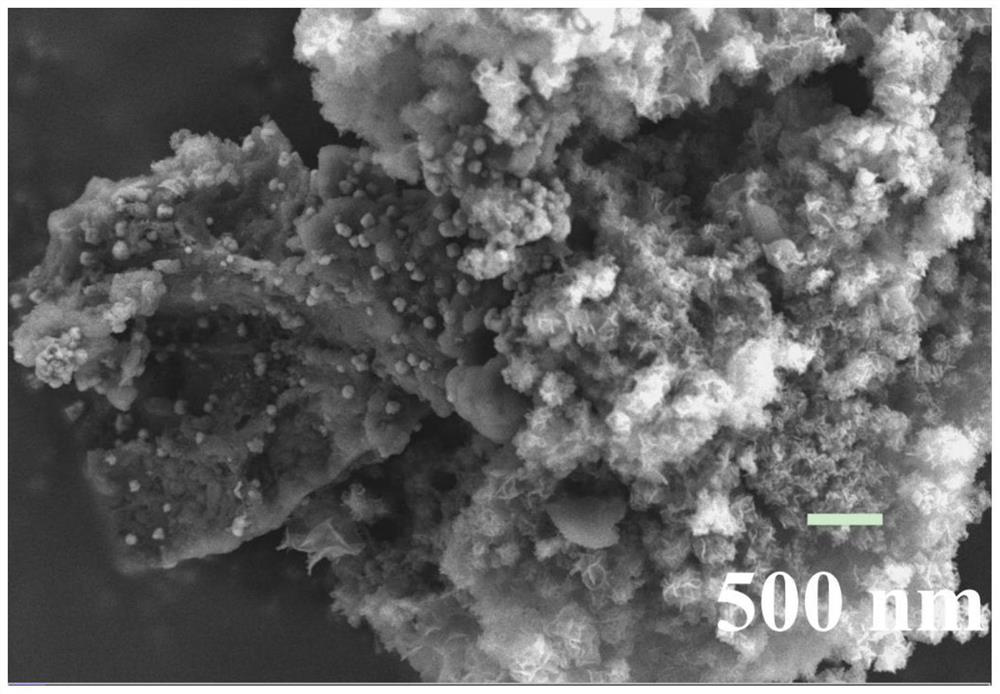

[0052] 1. The preparation of iron-based biochar comprises the following steps:

[0053] (1) The rice husk was air-dried naturally, ground and passed through a 100-mesh sieve, placed in a tube furnace, and purified with purified nitrogen for 15 minutes. Under nitrogen conditions, the dried rice husk powder was pyrolyzed at 500 °C for 60 min (flow rate: 200 mL / min). After natural cooling, the obtained black residue was treated with 1 mol / L HCl solution, treated in 1 mol / L NaOH solution, washed repeatedly, and dried in an oven at 60 °C to obtain rice husk biochar (BC).

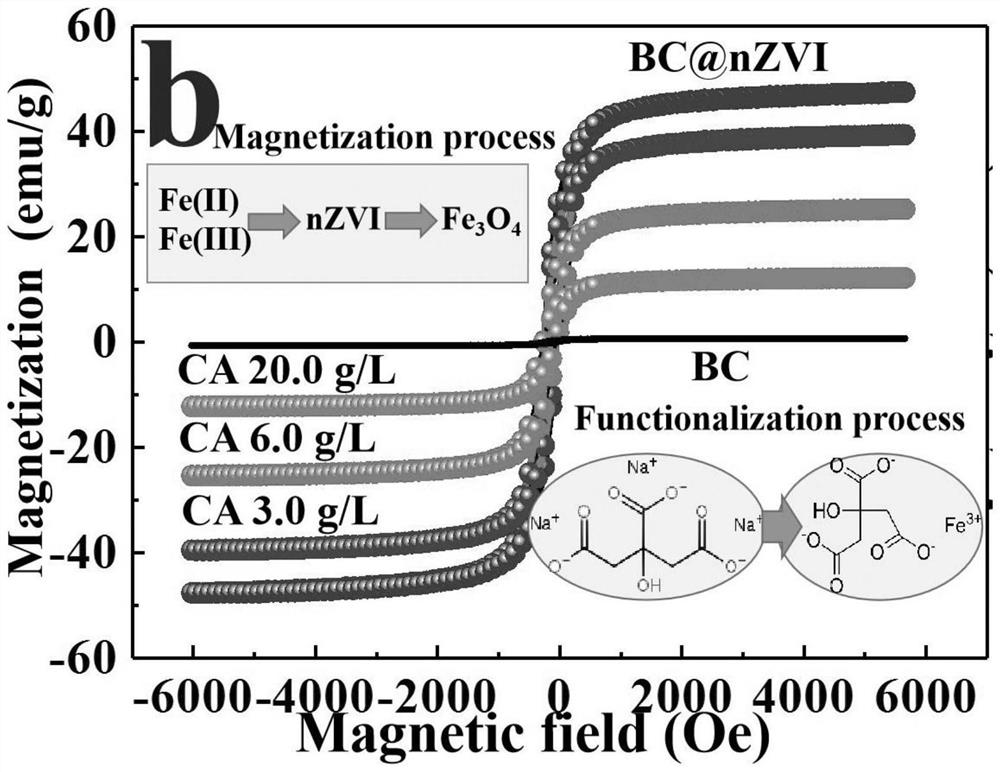

[0054] (2) Weigh 0.5g BC in (1) and disperse in 200mL 10g / L FeSO 4 ·7H 2 O solution, adjust the pH value of the above solution to 4.5. The mixture was transferred to a continuously stirred reflux apparatus, and 200 mL of 10 g / L NaBH 4 The solution was continuously dropped into the mixed solution, and the stirring was continued for 30 min after the dropwise addition to obtain a mixed solution of iron and bioch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com