A printed circuit board silk screen scraper assembly and solder resist ink filling system

A technology for printing circuit and solder mask ink, applied in printing, printing machine, rotary printing machine, etc., can solve the problems of poor quality of printed circuit board, scratched screen, affecting production efficiency, etc., so as to avoid affecting production, Avoid damage to the stencil, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

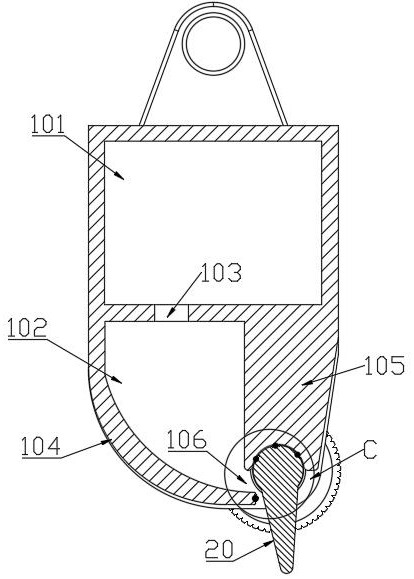

[0039] Such as Figure 2 to Figure 7 As shown, a printed circuit board silk screen scraper assembly includes: a mounting tube 10 and a scraper 20 .

[0040] Specifically, such as image 3 and Figure 4 As shown, the installation tube 10 includes an upper cavity 101 and a lower cavity 102 arranged downwards in a cross-sectional view along the length direction, and both the upper cavity 101 and the lower cavity 102 can be used to store solder resist ink. There are communication holes 103 between the upper cavity 101 and the lower cavity 102 , and a plurality of communication holes 103 are arranged at intervals along the length direction of the installation tube 10 to facilitate the circulation of the solder resist ink. The upper cavity 101 is provided with a feed joint 11 for filling solder resist ink, and the lower cavity 102 is provided with an outlet joint 12, which is in a normally closed state. When working, the outlet joint 12 is closed to prevent the solder resist ink f...

Embodiment 2

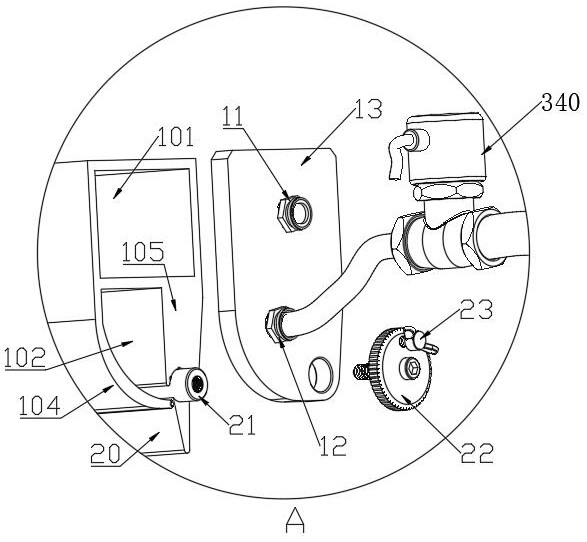

[0049] Such as figure 1 As shown, a printed circuit board solder resist ink filling system includes the printed circuit board silk screen scraper assembly of Embodiment 1 and a feeding device 300 .

[0050] The feeding device 300 includes a storage tank 310. The storage tank 310 is provided with a discharge pipe 311 and a recovery pipe 312. The discharge pipe 311 is provided with a discharge pump 330 to extract the solder resist ink in the storage tank 310. The feed joint 11 Both are connected with the discharge pipe 311, the outlet joint 12 is connected with the recovery pipe 312, and the recovery pipe 312 is provided with a valve 340, and the valve is in a normally closed state.

[0051] Such as figure 1 and Figure 8 As shown, the feeding device 300 also includes an agitator 320, and the agitator 320 includes a cover plate 321 for sealing the storage tank 310. The bottom of the cover plate 321 is provided with a rotating stirring shaft 322, and the bottom is provided with...

specific Embodiment approach

[0054] Specific implementation: when in use, the valve 340 is in a closed state, and the solder resist ink and additives are added into the storage tank 310 from the feeding nozzle 3211, or the mixed solder resist ink is put into the storage tank 310, and the agitator 320 is used to Stir the solder resist ink in the storage tank 310 to prevent the additives in the solder resist ink from sinking to the bottom and maintain the stability of the viscosity of the solder resist ink; The joint 11 is injected into the upper cavity 101 of the installation pipe 10, and the solder resist ink enters the lower cavity 102 from each communication hole in the upper cavity 101, and then is discharged through the discharge port 106, and flows into the net along the side wall of the scraper 20. plate. Because the solder resist ink pumped out by the discharge pump 330 can be injected in a pulse form, so that the flow rate of the solder resist ink fluctuates, the upper cavity 101 can stabilize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com