Method for heat preservation of molten steel in abnormal molten steel tank

A technology for molten steel tanks and abnormalities, which is applied in the field of molten steel insulation for abnormal molten steel tanks, can solve problems such as reducing the operation rate of casting machines, affecting the superheat of molten steel in tundishes, and unfavorable inclusions, etc., achieving convenient and easy technology, reducing labor intensity, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

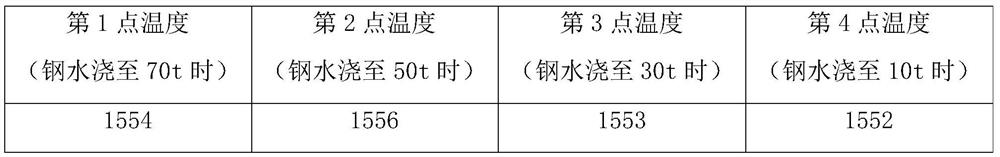

[0034] Refined LF furnace produces steel SWRCH22A, medium package target temperature is 1555 ± 5 ° C, and the total length of the large can turn interval is 8 hours and 25 minutes. This steel tank determination level is a can, which belongs to an abnormal steel jug, internal control ingredient Requirements are required to be controlled at 1590 ± 5 ° C as follows.

[0035] element C,% Si,% Mn,% P,% S,% ALS,% Standard range 0.18-0.22 ≤0.10 0.70-1.00 ≤0.025 ≤0.020 0.015-0.055 Target value 0.20 ≤0.10 0.80 ≤0.025 ≤0.020 0.030

[0036] When the steel component is adjusted, the control requirements are met, the tanker stopped the temperature of 1592 ° C, the steel tank stops the bottom blown argon, the lower electrode to the slag interface, and then the temperature control operation, the time controls 2 min, the temperature is completed, and the electrode is increased, this It is strictly forbidden to stir argon stir, and the steel tanker is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com