Piezoelectric photocatalyst, preparation method and application

A photocatalyst and piezoelectric technology, applied in the field of environmental science, can solve problems such as high current-carrying recombination rate, influence on application prospects, and limited research field of view, and achieve the effect of simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

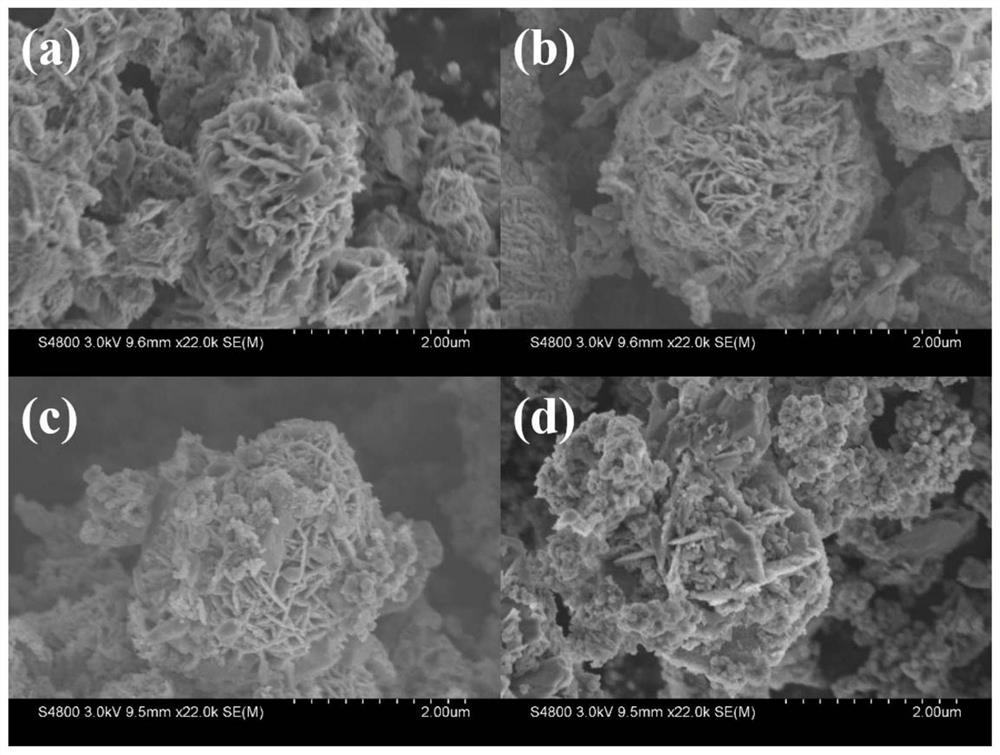

preparation example Construction

[0040] Preparation of CTOC: Pivalic acid (2.14g) and ethylene glycol (70ml) were mixed ultrasonically (40KHz) for 10min until the solution was clear, then tetrabutyl titanate (2.14ml) was added dropwise, and the mixed solution was subjected to ultrasound ( Power 120W, frequency 40KHz) for 10min, react at 100°C for 24h. The obtained product was washed three times with tetrahydrofuran, and dried under vacuum (0.09Mpa) at 60°C for 12h.

[0041] Preparation of CuS: Cu(NO 3 ) 2 ·3H 2 O (0.2416g, 1mmol) and ethylene glycol (40ml) were added to the reactor liner, followed by CH 4 N 2 S (0.1522, 2 mmol), the mixture was ultrasonically treated for 30 min, and reacted at 150°C for 24 h. The product was washed three times alternately with deionized water and ethanol, and dried at 60 °C for 4 h.

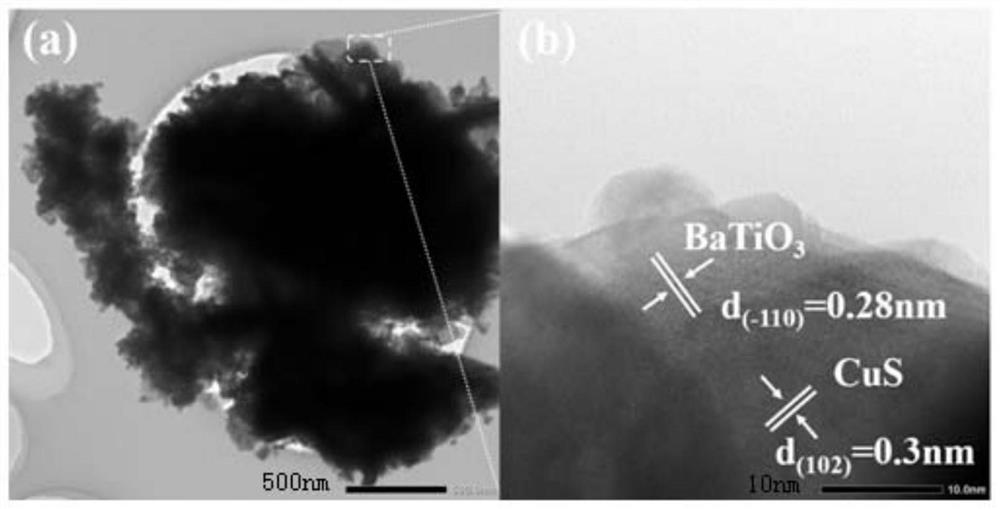

[0042] BaTiO 3 / CuS preparation: add 0.2g CuS prepared above to the lining of the reactor, add Ba(OH) 2 ·8H2 O (0.0271g) and TiO 2 (0.0068g), and 5ml of diethylene glycol, 5ml of ethano...

Embodiment 1

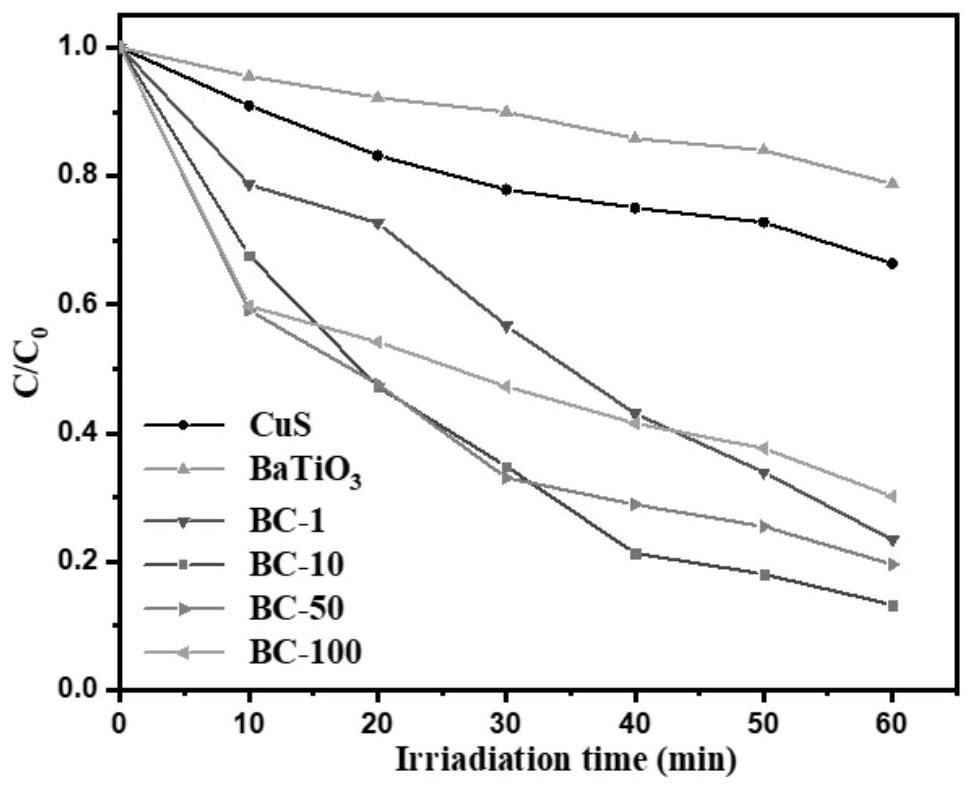

[0047] Binary composite BaTiO 3 / CuS is prepared by the following method: Weigh 0.2g of CuS prepared into the lining of the reactor, add Ba(OH) 2 ·8H 2 O (0.0027g) and TiO 2 (0.0007g), and 5ml of diethylene glycol, 5ml of ethanol, 1.5ml of isopropanol, 0.6g of tetrabutylammonium hydroxide solution (TBAH, 40wt%) and 7ml of deionized water were added as reaction solvents. The mixture was placed in an oven at 170°C for 4 h. The resulting product was washed with deionized water and ethanol and dried to obtain a mass ratio (m BaTiO3 :m CuS ) is 1wt% binary composite material BaTiO 3 / CuS, simplified as BC-1, and used for the degradation of tetracycline hydrochloride.

Embodiment 2

[0049] The present embodiment is different from Embodiment 1 in that: Ba(OH) 2 ·8H 2 O and TiO 2 The addition amounts of the two components are 0.0271g and 0.0068g respectively, and the mass ratio of the binary composite material is 10wt%, which is simplified as BC-10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com