Application of metal nanocluster catalyst in one-step preparation of acetal from alcohol

A technology of metal nano-clusters and catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, preparation of organic compounds, physical/chemical process catalysts, etc. The effect of less product and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 50mg of HAuCl 4 . 4H 2 O mix K 2 PtCl 4 Dissolved in 20 mL of dichloromethane (HAuCl 4 . 4H 2 O and K 2 PtCl 4 The molar ratio of sodium borohydride is 0.125:1), add the thiol ligand in the ratio of 5:1 and stir at room temperature for 30 minutes, then dissolve 10 mg of sodium borohydride in 1 mL of 4 ℃ water, add the above solution to reduce, and precipitate slowly. Slowly turned brown, indicating the formation of AuPt alloy nanoparticles. After the reaction was carried out for 1-5 days, the absorption peak of the product was characterized by UV-Vis absorption spectrum, which proved that AuPt nanoclusters were formed. Finally, the alloy nanoclusters were purified, and the product dissolved in dichloromethane was spin-dried, then washed with methanol three times, extracted with methylene chloride, and finally spin-dried. 50 mg of alloy nanoclusters were dissolved in 20 mL of dichloromethane, and 500 mg of Al was added 2 O 3 The carrier was centrifuged to dry...

Embodiment 2~4

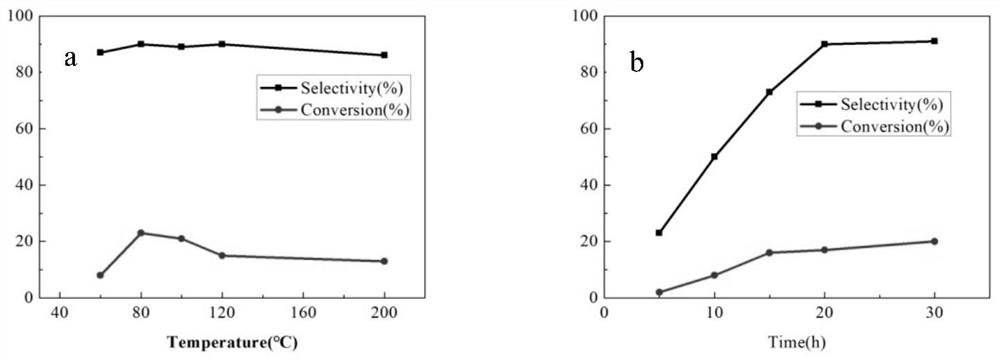

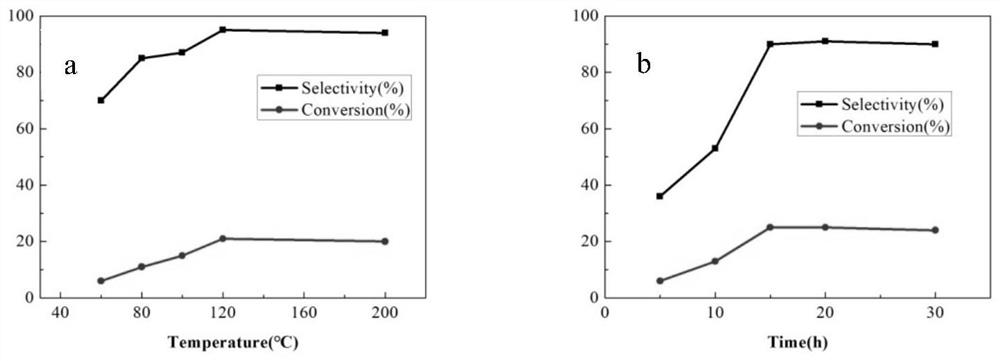

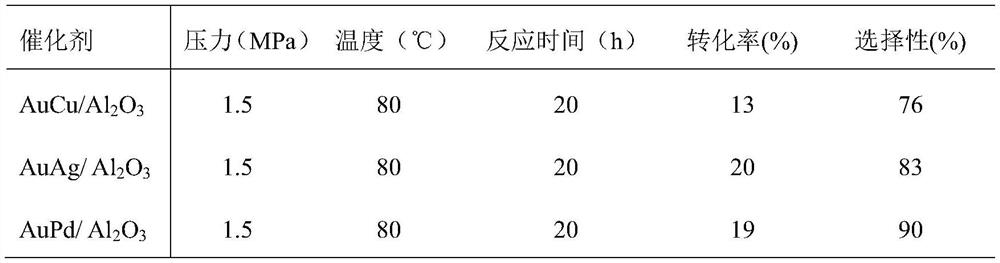

[0027] The experimental method and procedure are the same as in Example 1, and methylal is prepared by catalytic oxidation of methanol with different catalysts. The substrate was 10 mL of methanol, put into the reaction kettle, and then filled with oxygen, the reaction pressure was reduced to 1.5 MPa, and the reaction temperature was 80 °C, and the reaction started. The reaction was stopped after stirring for a period of time. After the temperature dropped to room temperature, the product was taken out, and the results were analyzed by GC-MS after centrifugal filtration. The specific results are shown in Table 1. Then select the AuPt / Al with the best catalytic activity 2 O 3 Alloy nanoclusters as catalysts to catalyze the oxidation of methanol to methylal. The selectivity and conversion of methanol catalytic oxidation to methylal at different temperatures and different reaction times were investigated. For specific results, see figure 1 .

Embodiment 5

[0029] 50mg of HAuCl 4 . 4H 2 O mixed AgNO 3 Dissolved in 20 mL of dichloromethane (HAuCl 4 . 4H 2 O and AgNO 3 The molar ratio of sodium borohydride is 0.125:1), add the thiol ligand in the ratio of 5:1 and stir at room temperature for 30 minutes, then dissolve 10 mg of sodium borohydride in 1 mL of 4 ℃ water, add the above solution to reduce, and precipitate slowly. Slowly turned brown, indicating the formation of AuAg alloy nanoparticles. After the reaction was carried out for 1-5 days, the absorption peak of the product was characterized by UV-Vis absorption spectrum, which proved that AuAg nanoclusters were formed. Finally, the alloy nanoclusters were purified, and the product dissolved in dichloromethane was spin-dried, then washed three times with methanol, extracted with dichloromethane, and finally spin-dried. 50 mg of alloy nanoclusters were dissolved in 20 mL of dichloromethane, and 500 mg of TiO was added 2The carrier was centrifuged to dry after 4 hours o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com