Nitrogen-doped MXene Pd-loaded catalyst as well as preparation method and application thereof

A nitrogen doping, catalyst technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of nitrogen-doped MXene loaded Pd catalyst, comprising the following steps:

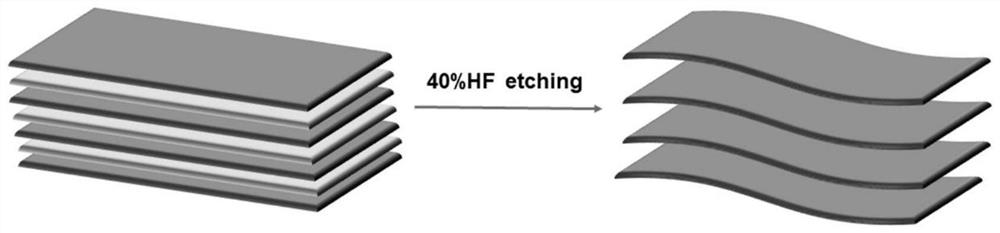

[0031] (1) The MXene material is mixed with the HF solution for etching to obtain the MXene carrier; the etching time is (24-32) h;

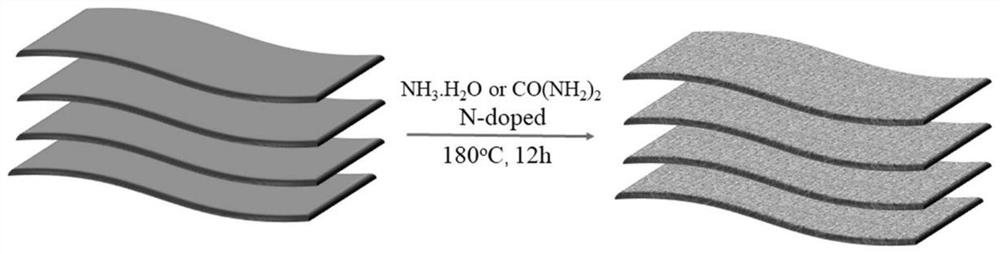

[0032] (2) the MXene carrier that described step (1) is obtained is mixed with nitrogen source, carries out hydrothermal reaction, obtains nitrogen-doped MXene carrier;

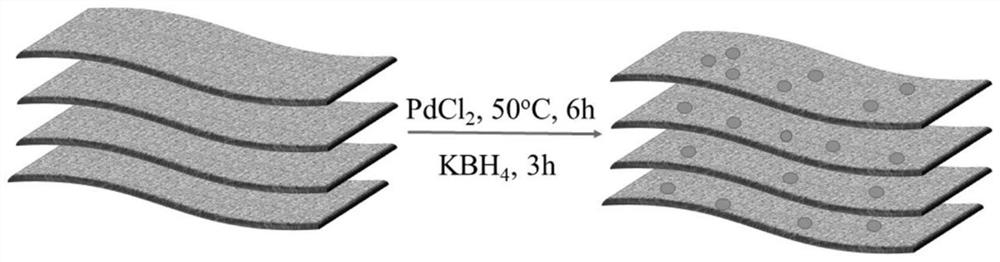

[0033] (3) the nitrogen-doped MXene carrier obtained in the step (2) is mixed with water and PdCl 2 The solutions are mixed, reacted at 50-60° C. for 4-6 hours, and then a reducing agent is added to carry out an oxidation-reduction reaction to obtain a nitrogen-doped MXene supported Pd catalyst.

[0034] In the invention, the MXene material is mixed with the HF solution for etching to obtain the MXene carrier.

[0035] In the present invention, the MXene material preferably includes Ti 3 AlC 2 、Ti 2 C, V 2 C and Mo 3 C 2 One or more of, ...

Embodiment 1

[0103] Ammonia doped etching of Ti for 28 hours 3 C 2 Carrier Pd-based catalyst

[0104] (1) Take a 50mL plastic beaker (put in a magnet), add 30mL of 40% HF solution into the beaker, and then weigh 2.5g Ti 3 AlC 2 (commercially available). Added to the HF solution in batches (completed in about 5 minutes), covered with plastic wrap, and stirred and reacted at room temperature for 28 hours. Centrifuge and wash with deionized water until the pH is about 6 (rotating speed is 10000r / min, 10min). The obtained product was transferred to a 50mL beaker, 30mL of absolute ethanol was added, and the ultrasonic time was 30min, which was completed three times. After suction filtration, dry at a constant temperature of 80°C to obtain an MXene carrier with a reaction time of 28 hours, hereinafter referred to as Ti 3 C 2 -28h.

[0105] (2) Using ammonia water as the nitrogen source, add 0.2g of Ti to a 50mL dry beaker 3 C 2 -28h sample, then add 30mL ammonia water with a concentrat...

Embodiment 2

[0112] (1) Same as the preparation method of Example 1 step (1), obtain the MXene carrier, referred to as Ti 3 C 2 -28h.

[0113] (2) With urea as the nitrogen source, add 0.2g of Ti to a 50mL dry beaker 3 C 2 -28h sample, then calculate the urea with the same N molar content as ammoniacal liquor in Example 1, by calculating the total mass of urea required is 9.75g, add urea 5.85g and 30ml water, wherein, the quality of MXene carrier and the nitrogen in urea The substance ratio of the element is 0.2g:0.67mol; ultrasonic crushing is used to reduce the particle size, and the ultrasonic wave is divided into 3 times for a total of 15 minutes. The mixture is transferred to the reactor, and 3.9g and 20mL of urea are added. water. The reaction conditions were heating at 180°C for 12h. After cooling, suction filter and wash with deionized water until the pH value of the supernatant reaches 7. Dry in a blast oven at 80°C for 12 hours to obtain N-Ti 3 C 2 -28h vector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com