Quantum dot material and preparation method thereof, quantum dot film, backlight module and display equipment

A technology of quantum dot material and quantum dot film, applied in the field of liquid crystal display, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

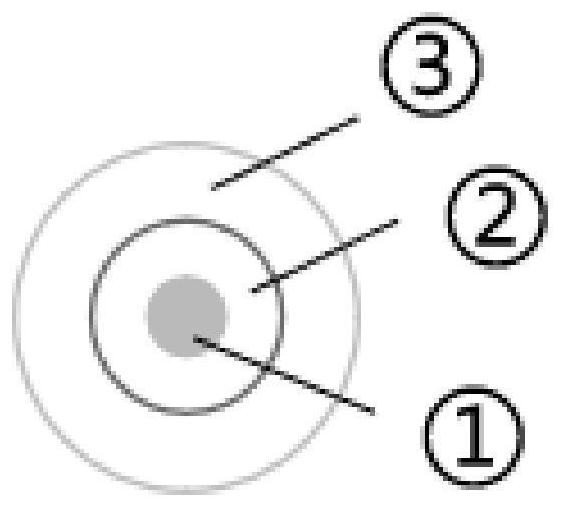

[0022] In the first aspect, the embodiment of the present application provides a method for preparing a quantum dot material, including: encapsulating the quantum dot with an oxide by using an inverse microemulsion method to obtain quantum dot / oxide particles. Quantum dots / oxide particles are coated with polymers by dispersion polymerization to obtain quantum dots / oxide / polymer particles, which are quantum dot materials.

[0023] In some embodiments of the present application, the preparation steps of quantum dots / oxide particles include: sequentially mixing and reacting quantum dot solution with dispersant, linker, amphoteric solvent, water, and oxide precursor, and precipitating to obtain a precipitate.

[0024] The quantum dots used in the present application are quantum dots formed of II B group elements and VI A group elements and / or quantum dots formed of III A group elements and V A group elements. Wherein, the II B group element can be cadmium or zinc, the VI A group e...

Embodiment 1

[0059] This embodiment provides a quantum dot material CdSe@ZnS / SiO 2 / PS and preparation method thereof, including:

[0060] Quantum dots CdSe@ZnS coated with silica.

[0061] 1. Add 170 μl of quantum dot chloroform solution (concentration 120 mg / ml) into 20 ml of cyclohexane to prepare a solution with a quantum dot concentration of 1 mg / ml.

[0062] 2. Add 10 μl of mercaptopropyltriethoxysilane (MPTS) to the above solution, stir for 30 minutes, and rotate at 500 rpm.

[0063] 3. Continue to add 2.4ml nonylphenol polyoxyethylene ether (NP-5), and keep stirring for 1 hour.

[0064] 4. Add 100 μl of ammonia water, keep stirring, and add 350 μl of tetraethyl silicate (TEOS) dropwise within 7 hours.

[0065] 5. Continue stirring for 9 hours, then add 25ml of ethanol to stop the reaction. Centrifuge at 7000 rpm for 3 minutes to separate the precipitate, discard the supernatant, and collect the precipitate.

[0066] 6. Add 20ml of ethanol to the precipitate, sonicate for 30min...

Embodiment 2

[0075] This embodiment provides a quantum dot material CdSe@ZnSe / TiO 2 / PS and preparation method thereof, including:

[0076] Quantum dots CdSe@ZnSe coated with titanium dioxide.

[0077] 1. Add 250 μl of quantum dot chloroform solution (concentration: 120 mg / ml) into 20 ml of cyclohexane to prepare a solution with quantum dot concentration of 1.5 mg / ml.

[0078] 2. Add 15 μl of mercaptopropyltriethoxysilane (MPTS) to the above solution, stir for 40 minutes, and rotate at 600 rpm.

[0079] 3. Continue to add 2.6ml of nonylphenol polyoxyethylene ether (NP-5), and continue to stir for 1 hour.

[0080] 4. Add 100 μl of ammonia water, keep stirring, and add 400 μl of tetrabutyl titanate (TBT) dropwise within 8 hours.

[0081]5. Continue stirring for 10 hours, then add 30ml of ethanol to stop the reaction. Centrifuge at 7500 rpm for 3.5 min to separate the precipitate, discard the supernatant, and retain the precipitate.

[0082] 6. Add 25ml of ethanol to the precipitate, son...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com