Chitosan-based multifunctional macromolecular rubber anti-aging agent, and preparation method and application thereof

A rubber antioxidant and multi-functional technology, which is applied in the field of rubber additives to achieve the effects of good compatibility, high reactivity and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

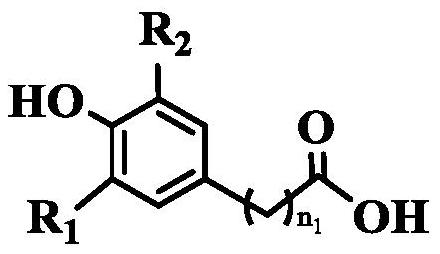

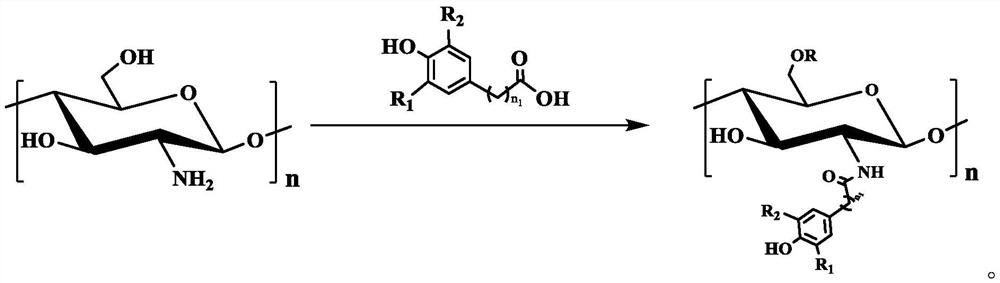

[0047] Embodiment 1: the synthesis of chitosan-based multifunctional macromolecular rubber antioxidant COS-AO-1

[0048] (1) In a 250mL three-neck flask equipped with mechanical stirring and nitrogen protection, add 3.0g (mole number of chain link 18.0mmol) chitosan (COS) (number average molecular weight is 3000), 2.5g (9.0mmol) carboxyl group-containing Phenolic antioxidant 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid (AO-1) and 100ml dimethyl sulfoxide were stirred for 24 hours, then 1.9g (9.0mmol) of dehydrating agent di Cyclohexylcarbodiimide and 0.11g (0.9mmol) catalyst 4-dimethylaminopyridine were reacted at 20°C for 96h to end the reaction;

[0049] (2) The reaction product obtained in step (1) was purified by post-processing such as filtration and washing, and then vacuum-dried to constant weight at 40°C to obtain chitosan-based multifunctional macromolecular rubber additive COS-AO-1.

[0050] COS-AO-1 was characterized by infrared spectroscopy and hydrogen nuc...

Embodiment 2

[0051] Embodiment 2: the synthesis of chitosan-based multifunctional macromolecular rubber antioxidant COS-AO-2

[0052] (1) In a 250mL three-neck flask equipped with mechanical stirring and nitrogen protection, add 3.0g (mole number of chain links: 18.0mmol) chitosan (COS) (number average molecular weight: 3000), 4.5g (27.0mmol) carboxyl-containing Phenolic antioxidant 3-(3,5-dimethyl-4-hydroxyphenyl) formic acid (AO-2) and 150ml N-methylpyrrolidone were stirred for 12h, then 3.4g (40.5mmol) dehydrating agent N,N '-Diisopropylcarbodiimide and 0.64g (8.1mmol) catalyst pyridine were reacted at 40°C for 48h to end the reaction;

[0053] (2) After the reaction product obtained in step (1) is filtered, washed and purified, it is vacuum-dried to constant weight at 40°C to obtain chitosan-based multifunctional macromolecular rubber additive COS-AO-2.

[0054] COS-AO-2 was characterized by infrared spectroscopy and hydrogen nuclear magnetic resonance spectroscopy. Compared with chi...

Embodiment 3

[0055] Embodiment 3: the synthesis of chitosan-based multifunctional macromolecule rubber antioxidant COS-AO-3

[0056] (1) In a 250mL three-necked flask equipped with mechanical stirring and nitrogen protection, add 3.0g (molar number of chain segments: 18.0mmol) chitosan (COS) (number average molecular weight: 3000), 15.1g (54.0mmol) carboxyl group-containing Phenolic antioxidant 3-(3-methoxy-5-tert-butyl-4-hydroxyphenyl)valeric acid (AO-3) and 100ml N,N-dimethylformamide and 100ml dimethyl sulfoxide After stirring the mixed solvent for 12 hours, add 18.2g (135.0mmol) dehydrating agent 1-hydroxybenzotriazole and 2.73g (27.0mmol) catalyst triethylamine, react at 60°C for 24h, and end the reaction;

[0057] (2) After the reaction product obtained in step (1) was purified by post-processing such as filtration and washing, it was vacuum-dried to constant weight at 40° C. to obtain chitosan-based multifunctional macromolecular rubber additive COS-AO-3.

[0058] COS-AO-3 was char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com