Plasma photocatalytic material and preparation method thereof as well as application of plasma photocatalytic material in preparation of aniline

A photocatalytic material and plasma technology, which is applied in the fields of energy science and catalytic science, can solve problems such as poor chemical activity, poor aniline conversion rate and selectivity, and poor catalytic performance, and achieve low equipment requirements, low price, and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Another embodiment of the present invention provides a method for preparing a plasma photocatalytic material, the steps are as follows:

[0038] adding chloroauric acid to cetyltrimethylammonium bromide solution, and then adding sodium borohydride for reduction to obtain a seed solution;

[0039] Adding silver nitrate, chloroauric acid and ascorbic acid successively to the solution of cetyltrimethylammonium bromide and bromosalicylic acid to obtain a growth solution;

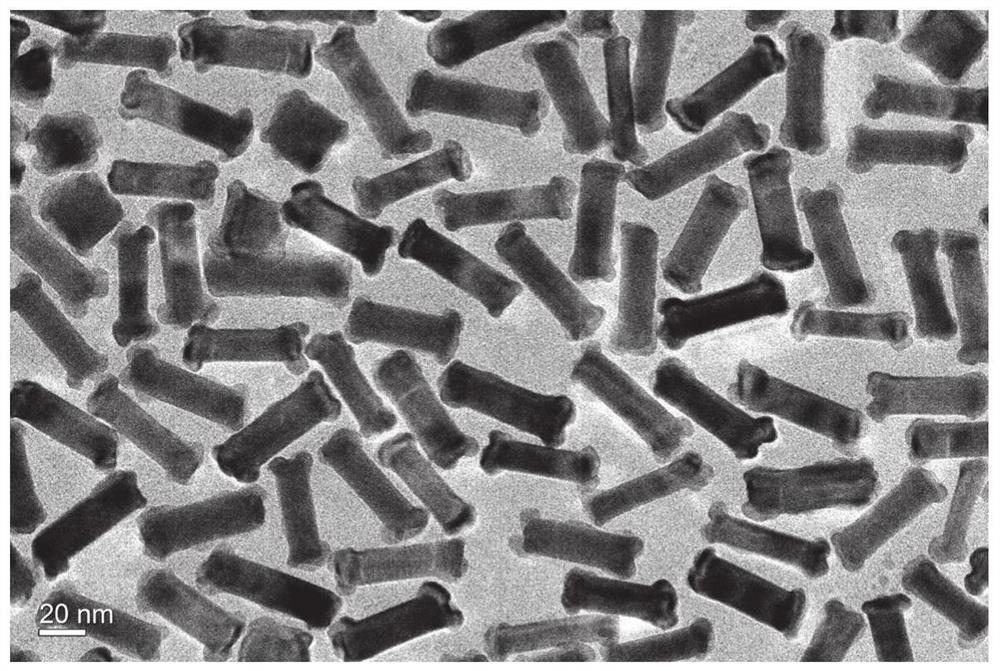

[0040] mixing the seed solution and the growth solution, and growing at 26-28°C to obtain gold nanorods;

[0041] Adding ascorbic acid, palladium chloride and hydrochloric acid to the gold nanorod solution, and growing it at 29-31°C to prepare a plasma photocatalytic material;

[0042] Wherein, the mass ratio of the volume of the seed solution to the cetyltrimethylammonium bromide in the growth solution is 1:10-15, mL:g, and the volume of the seed solution is 0.15-0.20% of the volume of the growth soluti...

Embodiment 1

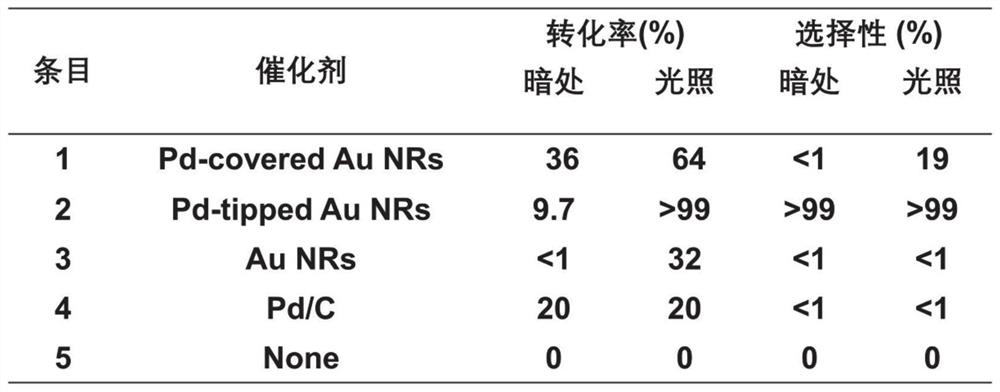

[0068] A Pd-Au plasma photocatalytic material (Pd-tipped Au NRs) coated with palladium at both ends and a preparation method thereof, comprising the steps of:

[0069] (1) Preparation of gold nanorods by seed crystal method:

[0070] Preparation of seed solution: Add chloroauric acid (250 μL, 0.01M) and sodium borohydride (600 μL, 0.01M) to cetyltrimethylammonium bromide solution (CTAB, 10 mL, 0.1M) in sequence, Stir for two minutes, then stand still for 30min to obtain the seed solution (the concentration of gold nanoparticles is ~2.3×10 -3 mol / L).

[0071] Preparation of growth solution: CTAB (3.6 g) and bromosalicylic acid (0.44 g) were weighed and dissolved in 100 mL of hot water at 50°C. Silver nitrate (1.90 mL, 0.01 M) was then added to the mixed solution. After standing still for 15 min, chloroauric acid solution (100 mL, 1 mM) was added and stirred slightly for 15 min. Then ascorbic acid (510 μL, 0.1 M) was added, and the mixture was continuously stirred until the ...

Embodiment 2

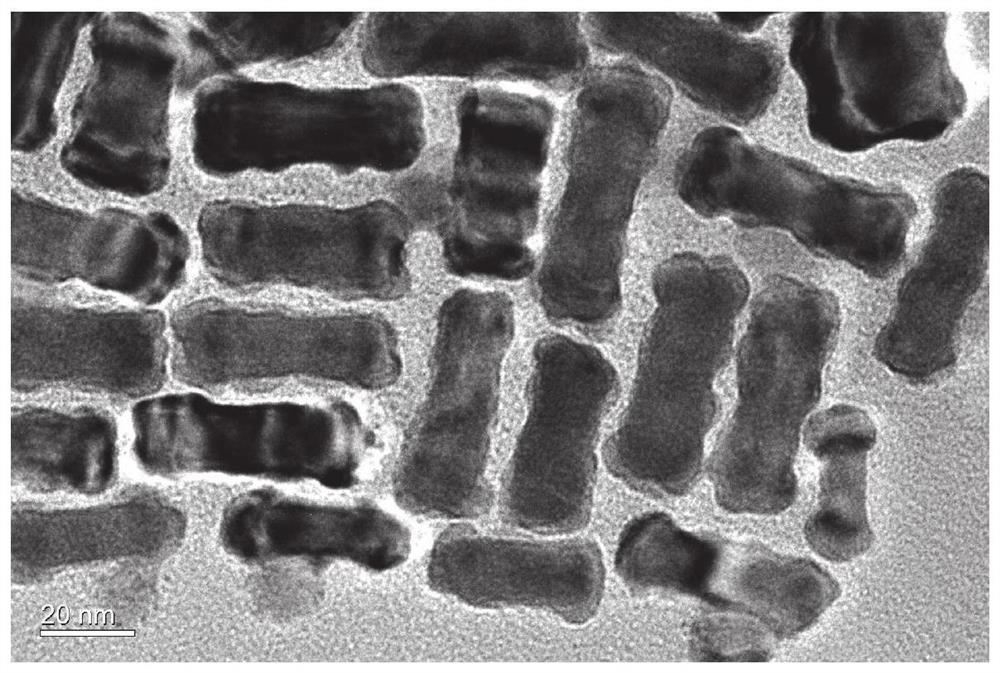

[0075] In this example, a Pd-Au plasma photocatalytic material (Pd-covered Au NRs) fully covered with palladium was prepared. The preparation method was the same as in Example 1, except that the surfactant in the growth solution in step (1) was changed to 7.288 g CTAB.

[0076] From figure 2 It can be seen that the surface of gold nanorods is covered by a layer of metal palladium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com