Large-flux low-pressure reverse osmosis membrane preparation method and device

A low-pressure reverse osmosis, high-throughput technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., to simplify the production process, realize stable and continuous production, save space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

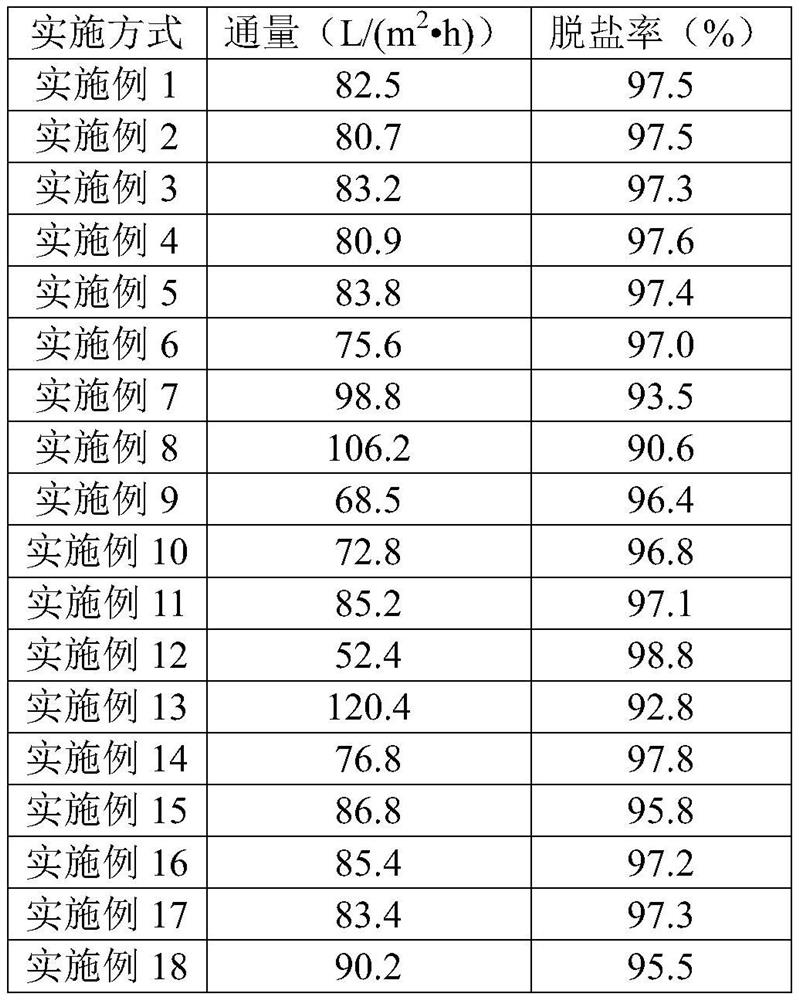

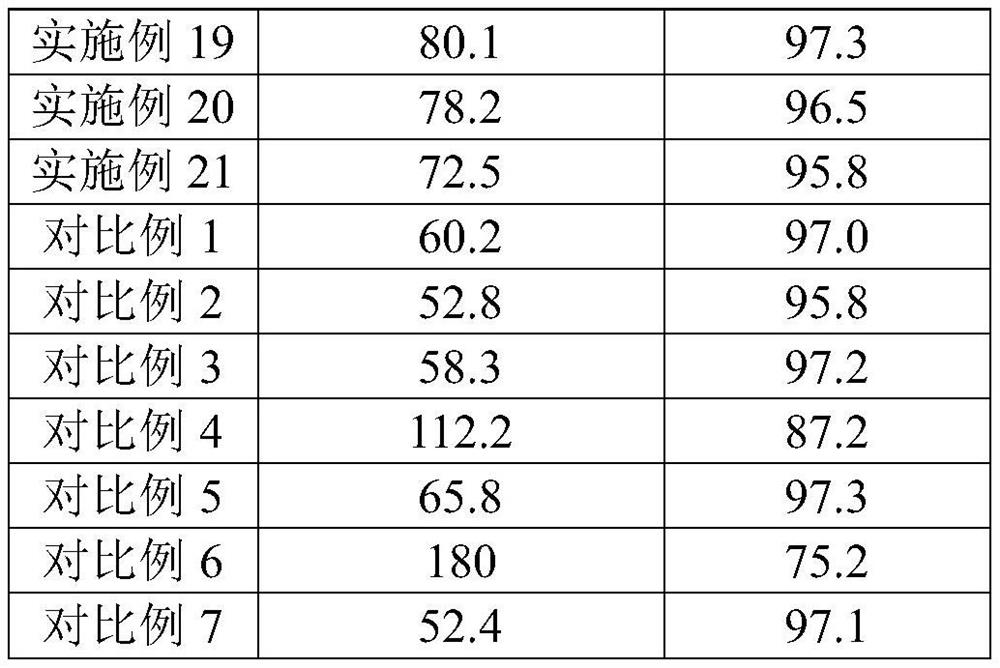

Examples

Embodiment 1

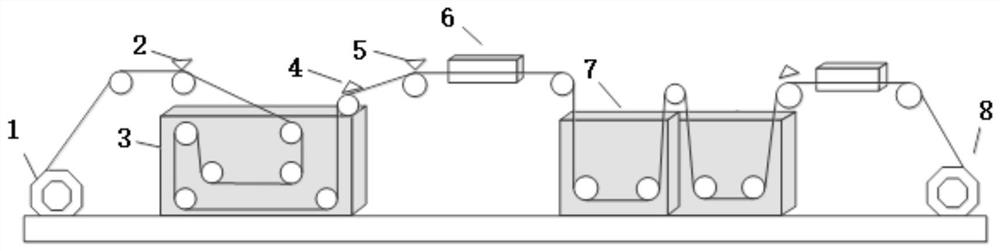

[0045] use figure 1 In the reverse osmosis membrane preparation device, the reverse osmosis membrane is prepared according to the following method:

[0046] Coat the polysulfone DMF casting solution with a mass concentration of 16% on the PET support and send it directly into the gel tank containing 1.2% m-phenylenediamine, 0.2% DMF and water, and stay in the gel tank at 30°C for 60s . Use an air knife surface drying device to blow off the excess solution until there are no visible drops of water on the surface, and start to coat 0.11% trimesoyl chloride ISOPARG oil phase monomer solution, which also contains 0.05% tributyl phosphate; After the interface reaction for 30s, dry at 70°C for 1min, then enter two consecutive 50°C pure water rinse tanks for cleaning; 6% glycerin water tank moisturizing treatment for 1min, and finally, send the formed film into a 70°C oven to dry for 2min, and wind up.

Embodiment 2

[0048] The reverse osmosis membrane was prepared according to the method and device in Example 1, the only difference being that the treatment temperature in the gel tank was adjusted to 32°C.

Embodiment 3

[0050] The reverse osmosis membrane was prepared according to the method and device in Example 1, except that the treatment temperature in the gel tank was adjusted to 35°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com