Disposable absorption product capable of rapidly conducting infiltration

An absorbent product, a disposable technology, applied in medical science, bandages, etc., can solve the problems of insufficient diversion and penetration effect, low utilization rate and dryness of disposable absorbent products, and damage to the baby's O-shaped legs, so as to improve dryness. and comfort, improving the diversion effect, and avoiding the hidden dangers of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

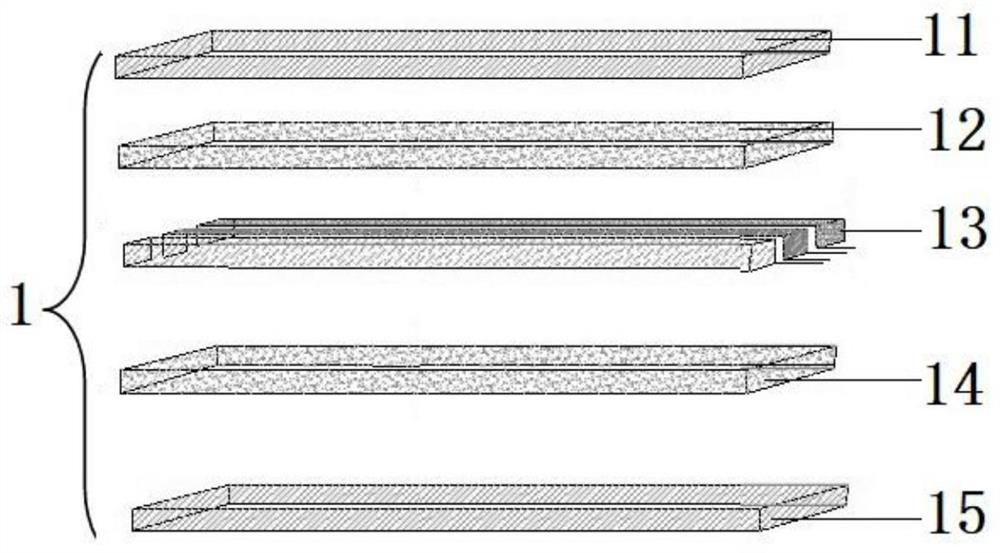

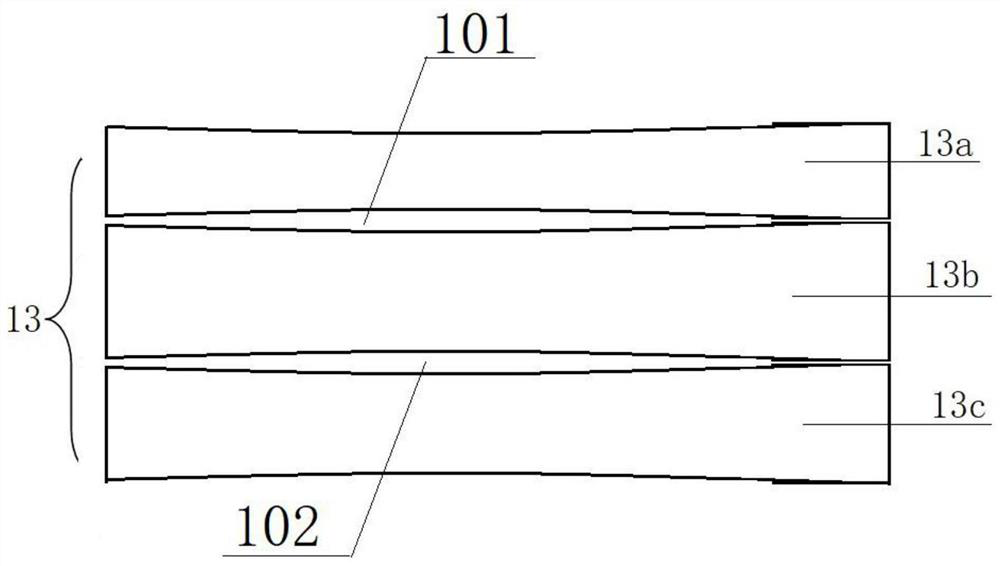

[0058] In this embodiment, the fluffy nonwoven fabric layer 13 is cut into three fluffy nonwoven fabric strips. Wherein, take the fluffy nonwoven fabric strip 13b located in the longitudinal midline region as the reference fluffy nonwoven fabric strip 13b, and respectively apply a reference tensile force to the two longitudinal ends of the reference fluffy nonwoven fabric strip, and the tensile force passes through the adjustment line The speed is achieved by making the loose nonwoven fabric deform and narrow in the width direction. Specific steps are as follows:

[0059] Step 1. Set the reference line speed of the fluffy nonwoven fabric strip 13b, whose width ratio is 80%.

[0060] Step 2. Set the fluffy nonwoven fabric strips 13a and 13c on both sides of the reference fluffy nonwoven fabric strips, adjust the line speed, and the width ratio is 80%.

[0061] Narrowing through the above-mentioned differential stretching, the fluffy nonwoven fabric 13a is deformed with refere...

Embodiment 2

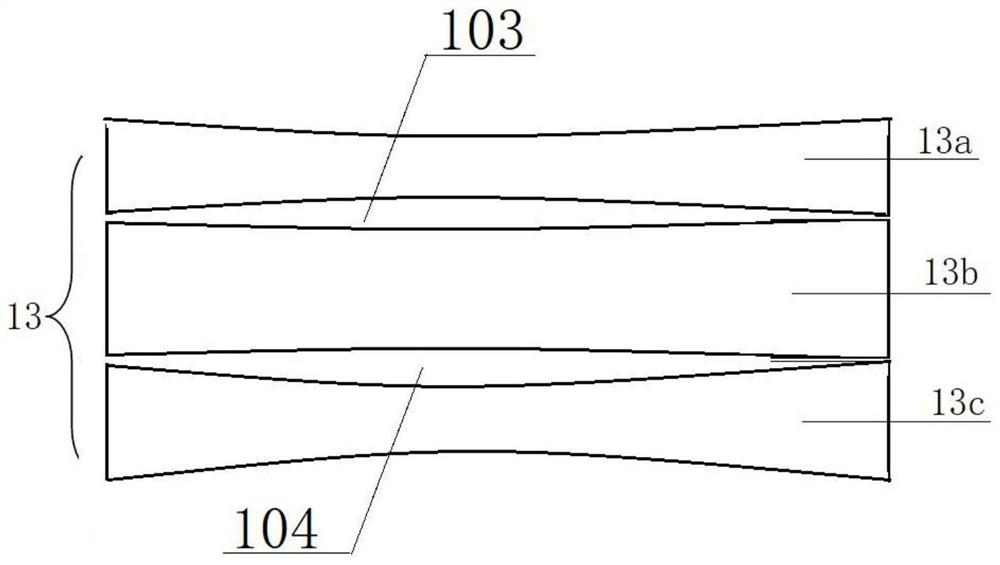

[0064] In this embodiment, between the fluffy nonwoven fabric strip 13a, the reference fluffy nonwoven fabric strip 13b, and between the fluffy nonwoven fabric strip 13b and the fluffy nonwoven fabric strip 13c, different proportions of deformations are produced in the width direction, Narrowing, forming a ladder-like linear velocity relationship between the reference fluffy nonwoven fabric strip and the fluffy nonwoven fabric layer measurement boundary. Therefore, the difference between the present embodiment and embodiment 1 is only that the reference line speed of the reference fluffy nonwoven fabric strip 13b in this embodiment, the fluffy nonwoven fabric strips 13a, 13c located on both sides of the reference fluffy nonwoven fabric strip The aspect ratio (line speed) setting is different.

[0065] Step 1. Set the reference line speed of the fluffy nonwoven fabric strip 13b, whose width ratio is 80%.

[0066] Step 2. Set the line speed of the fluffy non-woven fabric strips...

Embodiment 3

[0069] The difference between the present embodiment and embodiment 1 is only that the present embodiment refers to the reference line speed of the fluffy nonwoven fabric strip, and the width ratio (line speed) of the fluffy nonwoven fabric strip on both sides of the reference fluffy nonwoven fabric strip. speed) settings are different.

[0070] Step 1. Set the reference line speed of the fluffy nonwoven fabric strip 13b, whose width ratio is 80%.

[0071] Step 2. Set the line speed of the fluffy non-woven fabric strips 13a, 13c, and their width ratios are both 70%.

[0072] The flow-guiding permeable through-holes 105, 106 greatly enhance the flow-guiding effect of the composite absorbent core. The diversion and penetration through holes 105, 106 greatly improve the diffusion of the composite absorbent core, and obtain a composite absorbent core that can conduct infiltration rapidly, and its absorption speed, plane absorption performance and U-shaped pressure absorption perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com