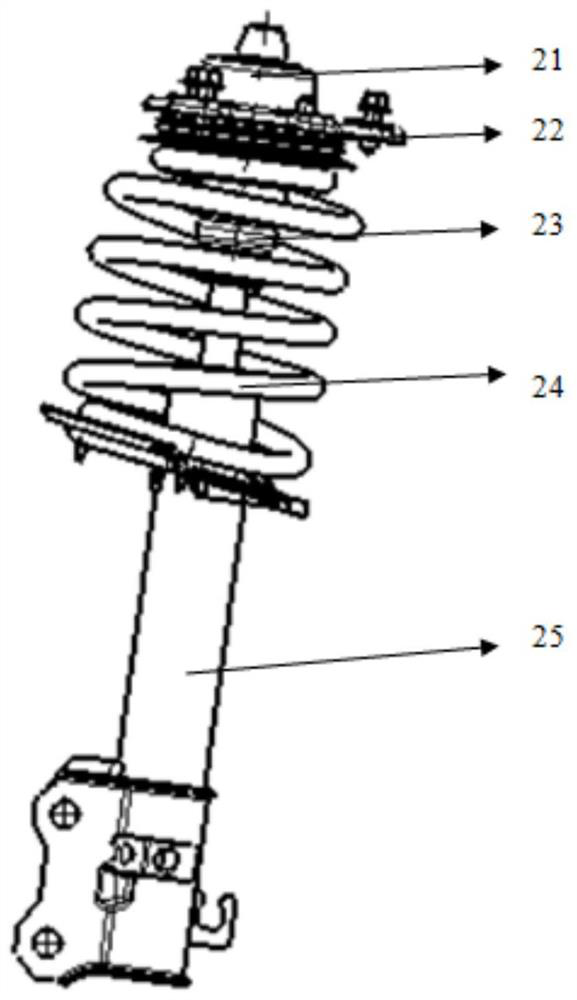

Shock absorber assembly load signal acquisition device

A load signal and acquisition device technology, applied in the field of vehicle shock absorbers, can solve problems affecting the accuracy of strain gauge signals, reduce the quality of collected signals, and reduce design accuracy, so as to improve development efficiency, signal quality, and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

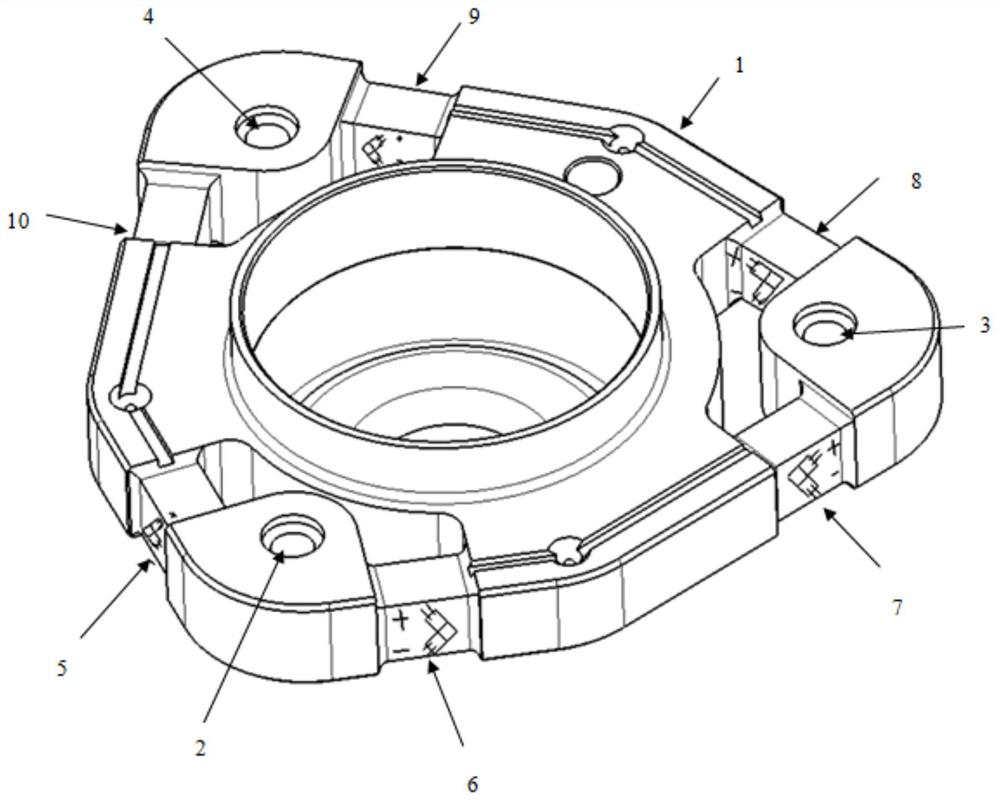

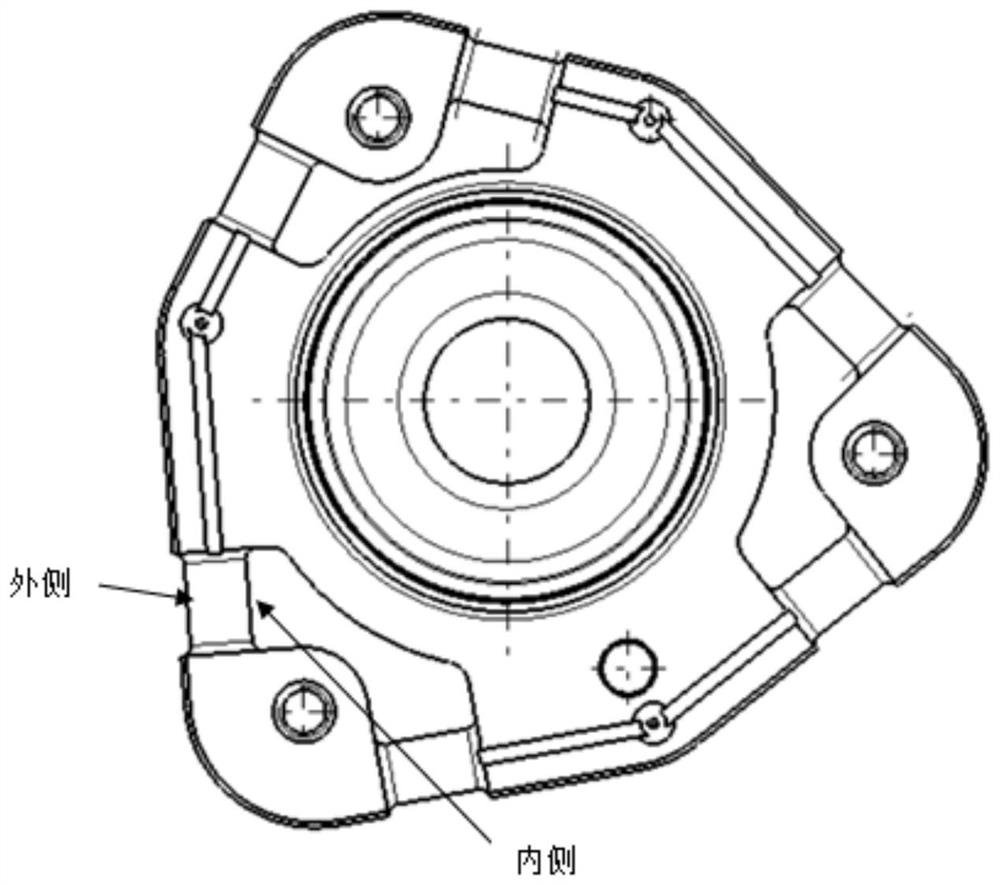

[0016] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0017]The invention provides a shock absorber assembly load signal acquisition device, which comprises a shock absorber assembly body 1, and the shock absorber assembly body 1 is evenly distributed along the circumferential direction with mounting holes 1, 2, and 3. Three 4, the left and right sides of installation hole one 2 are respectively provided with strain gauge installation groove one 5, strain gauge installation groove two 6, and the left and right sides of installation hole two 3 are respectively provided with strain gauge installation groove three 7, strain gauge installation groove four 8 , the left and right sides of installation hole three 4 are respectively provided with strain gauge installation groove five 9, strain gauge installation groove six 10, strain gauge installation groove one 5, strain gauge installation groove two 6, strain gauge insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com