Sequential supporting structure system of soil vertical shaft and construction method

A technology for supporting structures and shafts, which is used in shaft equipment, earth-moving drilling, wellbore lining, etc., can solve the problems of short self-stabilization time and poor stability of soil, save construction procedures, enhance integrity, increase Effects of stiffness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

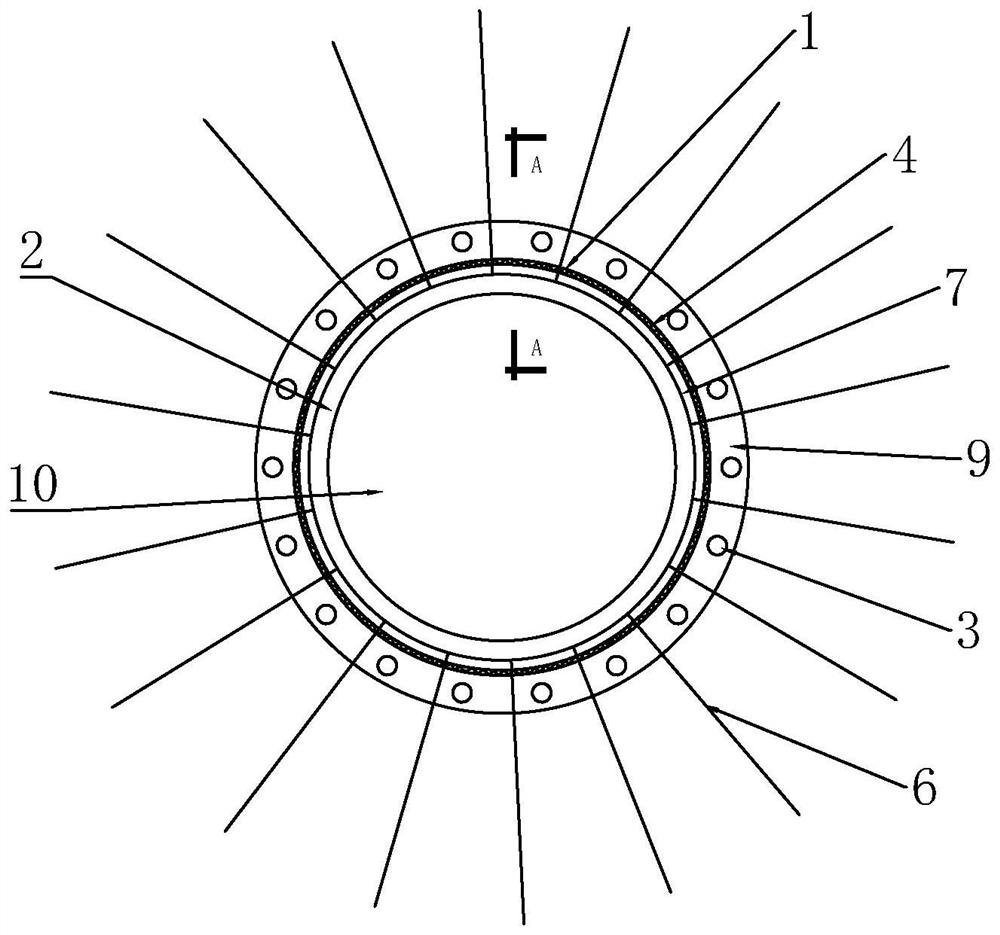

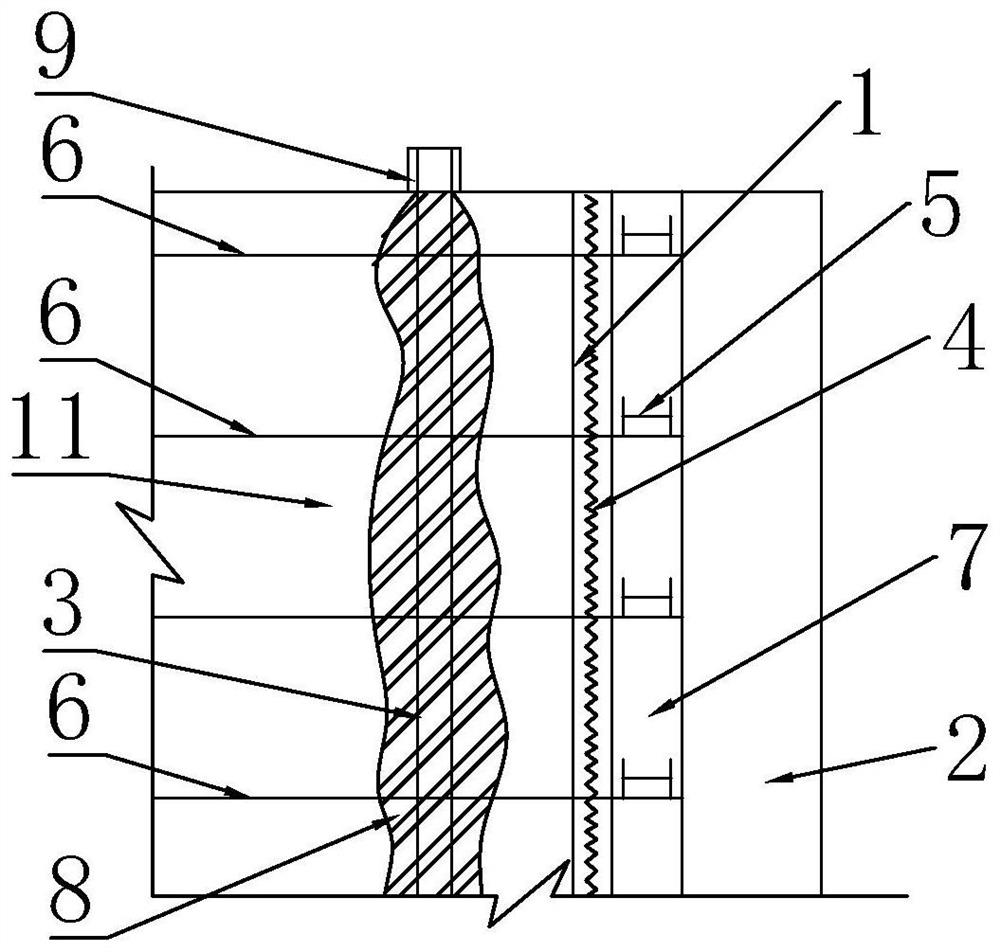

[0025] Such as figure 1 , figure 2 As shown, a sequenced support structure system of an earth shaft according to the present invention includes the shaft wall 1 of the excavation shaft 10, the advanced support structure arranged around the outside of the shaft wall 1, and the construction period support arranged around the inside of the shaft wall 1 Structure, and reinforced concrete shaft wall structure 2.

[0026] The advance support structure includes several grouted steel pipe piles 3 arranged around the outside of the shaft wall 1 . The pile body of the grouted steel pipe pile 3 is preset with seepage holes, and an anti-seepage body 8 is formed in the grouted steel pipe pile 3 by grouting. The top of the grouted steel pipe pile 3 is provided with a locking ring 9 connecting all the grouted steel pipe piles 3 . The grouted steel pipe p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com