Structure for reinforcing UHPC-NC interface bonding through spiral steel bars and manufacturing method

A technology of UHPC-NC and spiral steel bars, which is applied to structural elements, building reinforcements, building components, etc., can solve problems such as insufficient bonding, and achieve the effect of insufficient bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

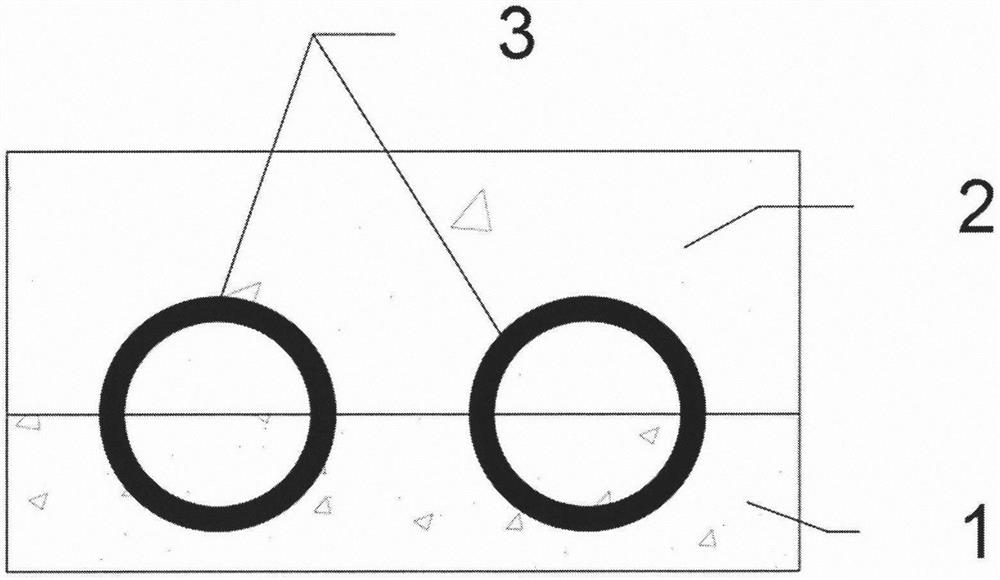

[0022] In order to have a deeper understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0023] Referring to the accompanying drawings, in an example of the present invention, a structure and a manufacturing method for strengthening UHPC-NC interfacial bonding using spiral steel bars. The spiral steel bar 3 is used as the connector between the interface of UHPC1 and NC2, which is composed of the lower layer UHPC1, the upper layer NC2 and the spiral steel bar 3.

[0024] The above-mentioned structure uses spiral steel bars to strengthen the bonding of the UHPC-NC interface, and the spiral steel bars 3 are made of high-quality high-strength steel bars.

[0025] In the structure of the UHPC-NC interface bonding reinforced by spiral steel bars, the nominal diameter of the spiral steel bar 3 is 1 / 3 to 1 / 5 of the height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com