A Grouting Method Applicable to Rock Mass Anchor Engineering of Flat-roofed Grotto Roof

A technology of flat roof and roof, which is applied in basic structure engineering, sheet pile wall, earthwork drilling and mining, etc., can solve problems such as the decline of anchoring capacity of bolts, affecting the quality of anchoring works, and unfavorable long-term preservation of ruins, and achieves convenient and economical application. Practical and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

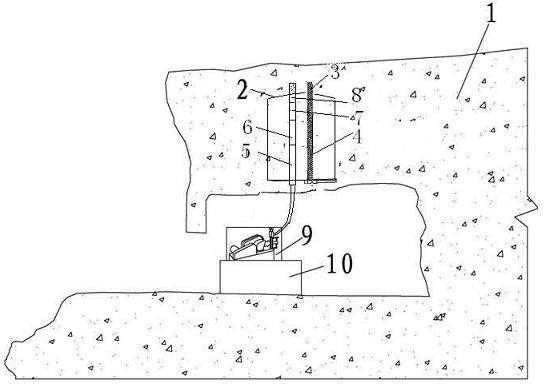

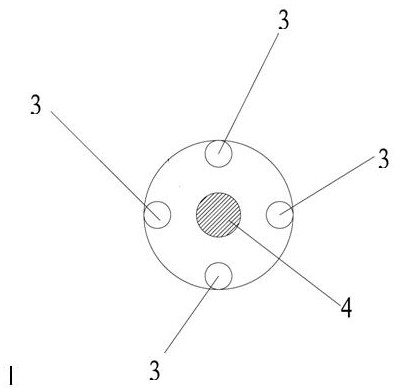

[0021] Below in conjunction with accompanying drawing and technical implementation method, further describe in detail again:

[0022] A grouting method suitable for rock mass anchorage engineering of flat-roofed grottoes, the method comprising:

[0023] (1) The drilling rig is fixed according to the hole position, and the drilling direction is vertical and upward. In order to prevent the adverse effect of engineering water on the rock mass 1 existing in the Grotto Temple, the anchor rods are all drilled with roller cone drills without water and dry with high-pressure wind. Pore slag. In order to reduce the damage caused by mechanical vibration to the stability of the cracked rock mass 2 on the roof of the flat-roofed grotto, a light, high-frequency impactor is used for impact drilling. In the thinner part of the rock formation, an alloy drill bit or a roller cone bit is first used to open holes to avoid vibration and ensure Cultural relics are safe. The depth of the anchor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com