High-speed railway bridge support mounting equipment

A technology for bridge bearings and high-speed railways, which is applied in bridge construction, bridges, bridge parts, etc., and can solve problems such as soaking, breaking, and slipping of rising rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

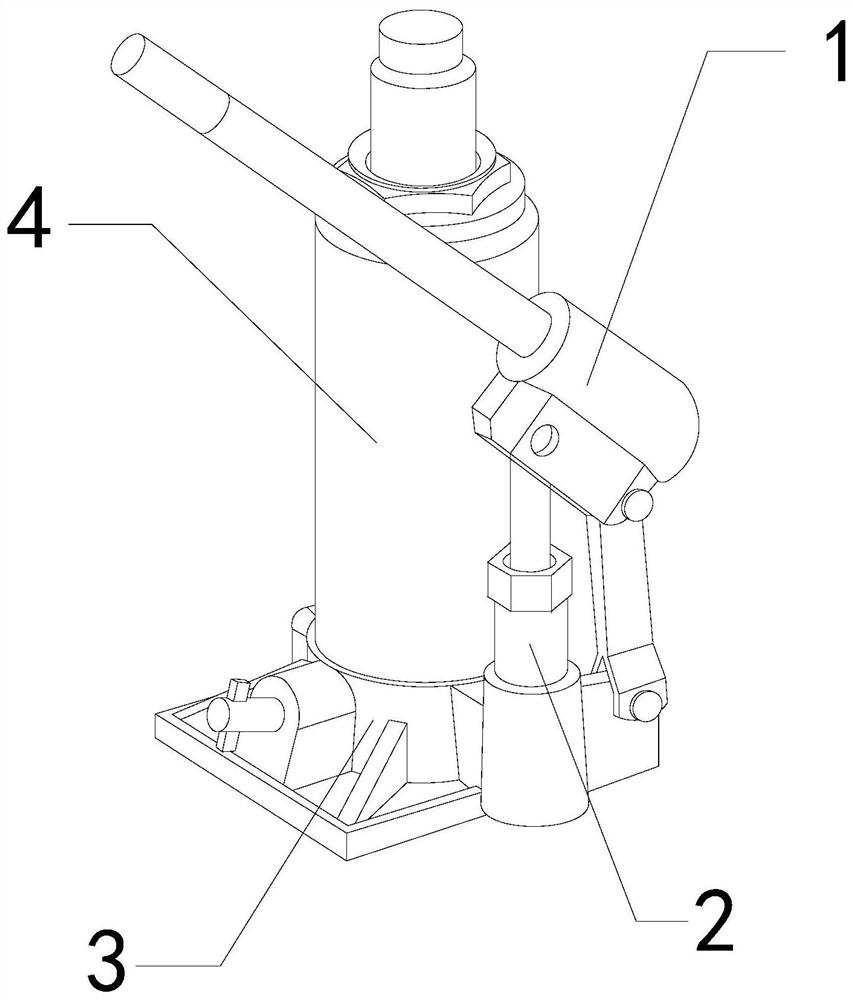

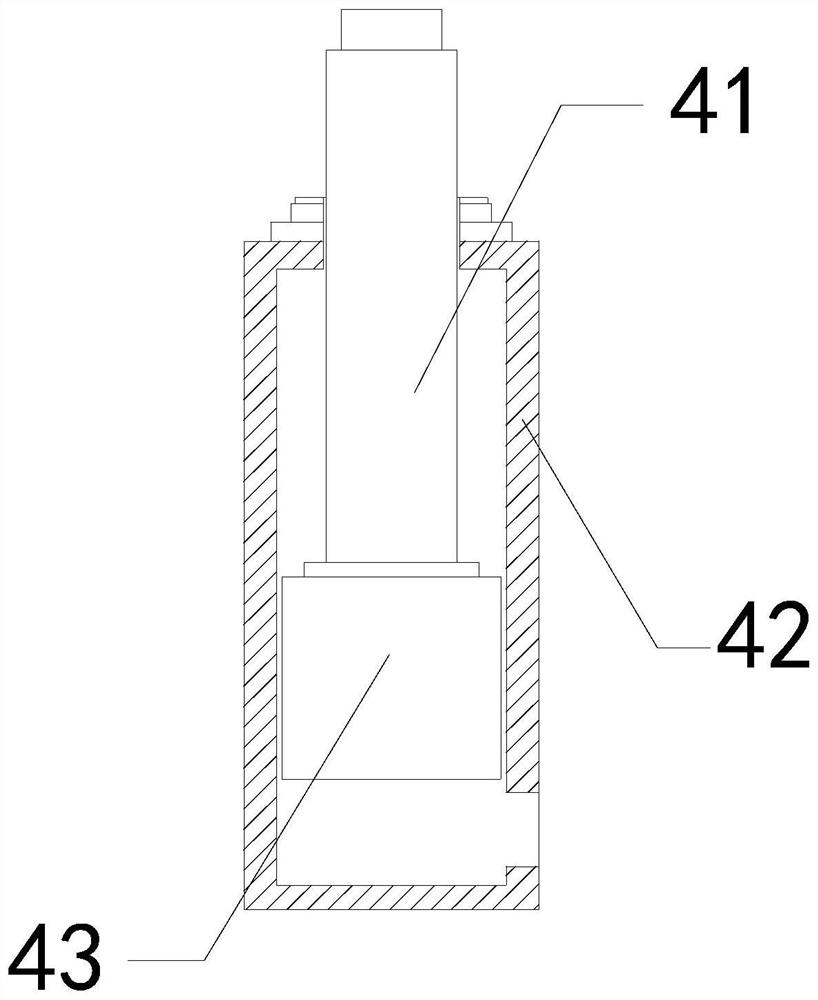

[0027] The invention provides a high-speed railway bridge support installation equipment, the structure of which includes a handle 1, a hydraulic chamber 2, a base 3, and a support mechanism 4, the handle 1 is hinged to the upper end of the hydraulic chamber 2, and the hydraulic chamber 2 is connected to the support The sides of the mechanism 4 are connected, and the support mechanism 4 is installed at the upper end of the base 3; the support mechanism 4 includes a rising rod 41, an outer tube 42, and a piston 43, and the inner movement of the rising rod 41 and the outer tube 42 snapping, the piston 43 is connected with the bottom of the rising rod 41 .

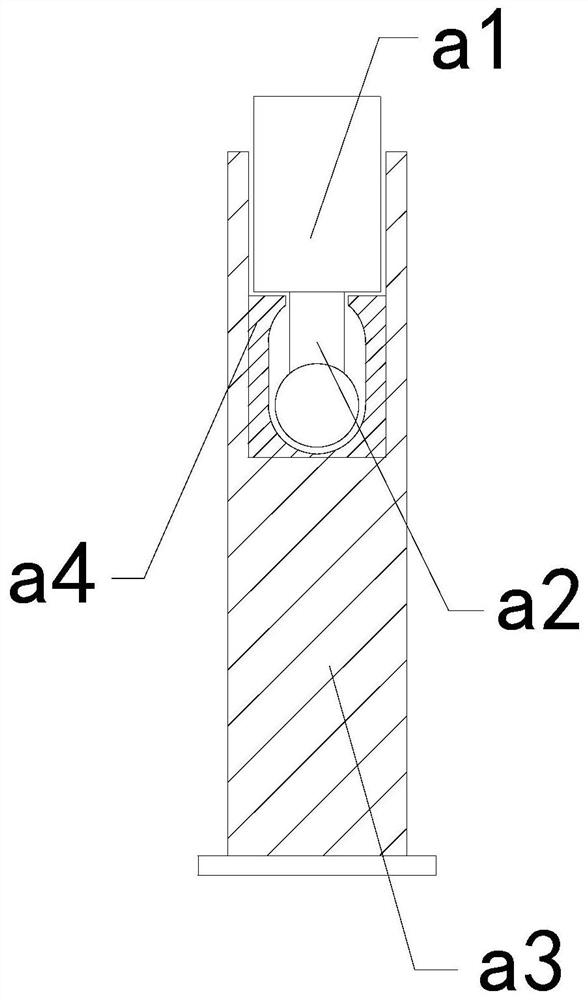

[0028] Wherein, the rising rod 41 includes an upward extension block a1, a linkage rod a2, a bottom plate a3, and an inner connection block a4. Internal movable engagement, the inner connection block a4 and the bottom plate a3 are an integrated structure, through the ...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035]Wherein, the plate body a14 includes a combination plate c1, a vibration plate c2, a pull-down piece c3, and a telescopic block c4, the bottom of the vibration plate c2 is connected to the upper end of the telescopic block c4, and the pull-down piece c3 is installed on the The inner position of the plate c2 and the connecting plate c1, the telescopic block c4 cooperates with the internal clearance of the connecting plate c1, through the vibration generated by the mechanism shrinking to the extreme, the telescopic block c4 can push the vibration plate c2 upward to protrude, and through the lower The pulling of the vibrating plate c2 by the pulling piece c3 can quickly reset the vibrating plate c2, so that vibration can be generated to loosen the cement on the upper surface of the vibrating plate c2.

[0036] Wherein, the vibrating plate c2 includes a middle rod c21, a bottom plate c22, a vibrating block c23, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com