An inflatable shaft repair device

An inflatable shaft, coaxial technology, applied in workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve problems such as difficulty in separating the inflatable end from the inflatable shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

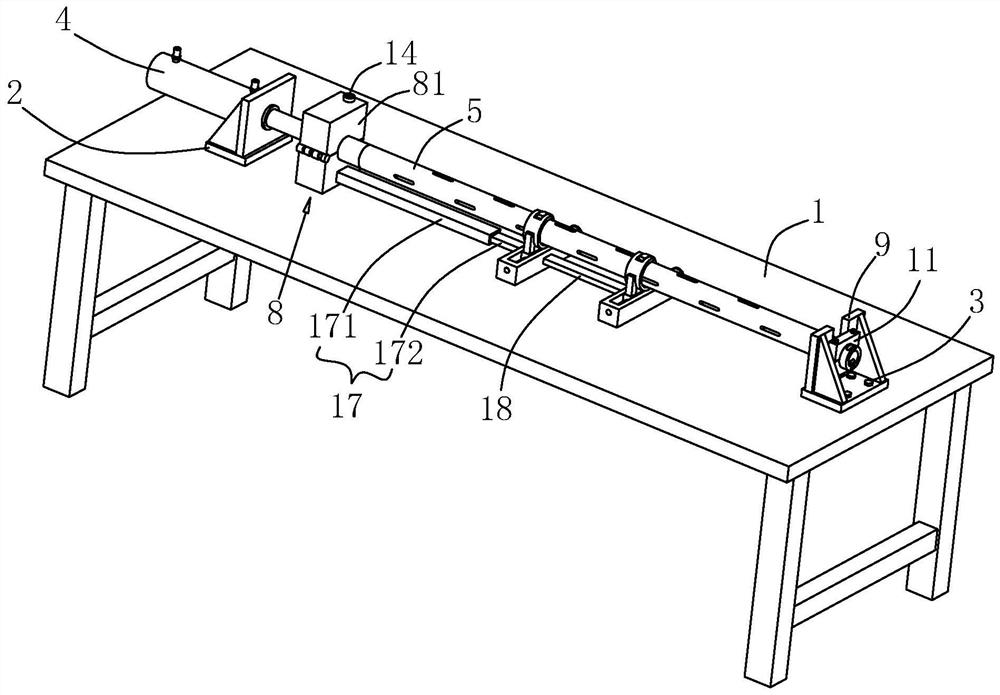

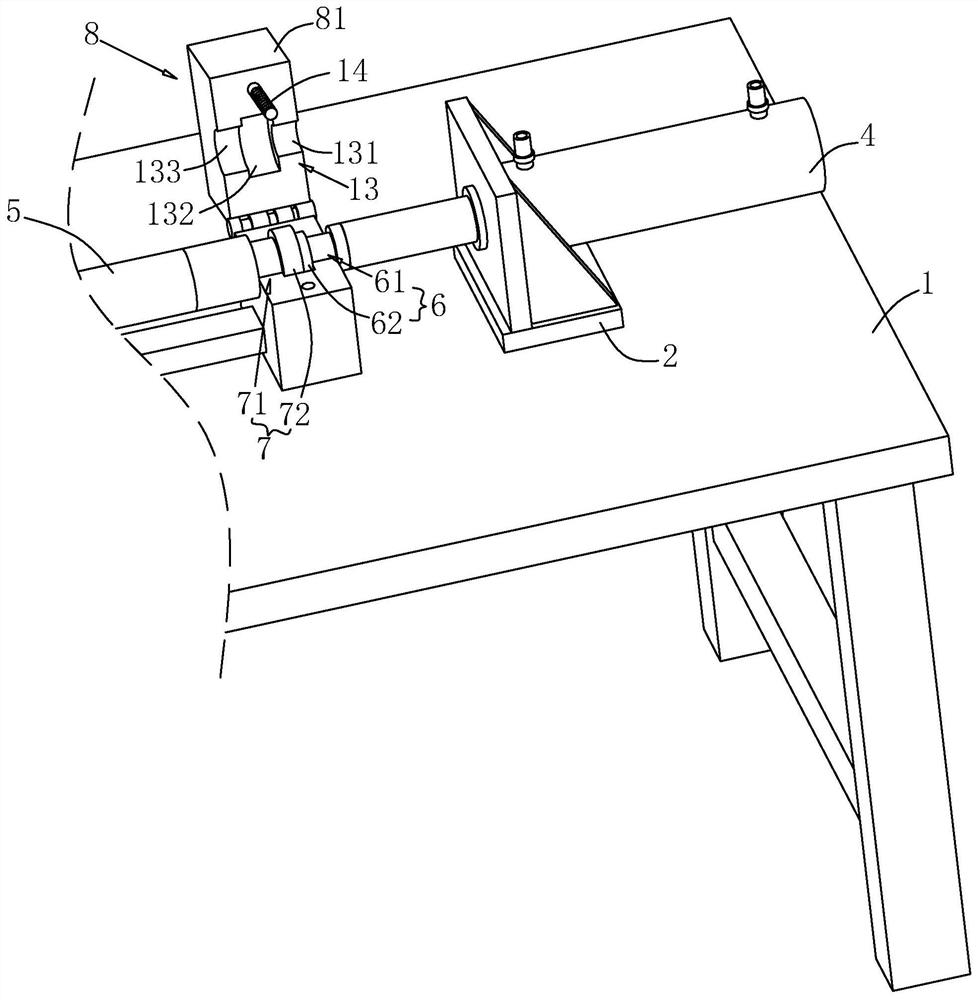

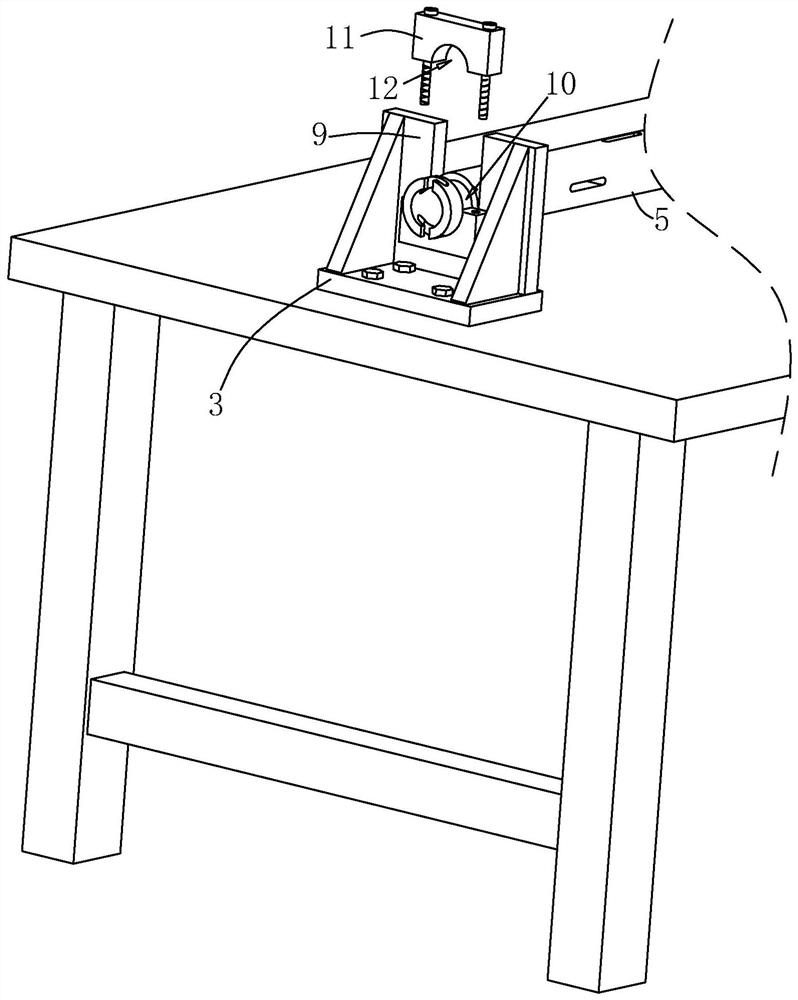

[0031] Attached to the following Figure 1-4 This application will be described in further detail.

[0032] The embodiment of the present application discloses a device for repairing an inflatable shaft. like figure 1 As shown, the inflatable shaft maintenance device includes a workbench 1 , a first clamping part 6 and a second clamping part 7 . A plurality of threaded holes are arranged on the table surface of the workbench 1 , and a first base 2 and a second base 3 are respectively detachably connected to the workbench 1 through screws. The first base 2 and the second base 3 are along the length of the workbench 1 . Orientation is set relative. A baffle plate is welded on the surface of the vertical table 1 on the first base 2, the cylinder body of the hydraulic cylinder 4 is penetrated and fixed in the baffle plate, the piston rod of the hydraulic cylinder 4 passes through the baffle plate, and the piston rod of the hydraulic cylinder 4 faces the second base 3 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com