Filter screen, preparation method of the filter screen and filtering device applying the filter screen

A filter device and filter screen technology, which is applied in the field of air purification, can solve the problems that the air cannot carry atomized water, the volume of the humidification component is large, and the thickness is not easy to control, so as to improve the filtration efficiency, high specific surface area, and high porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

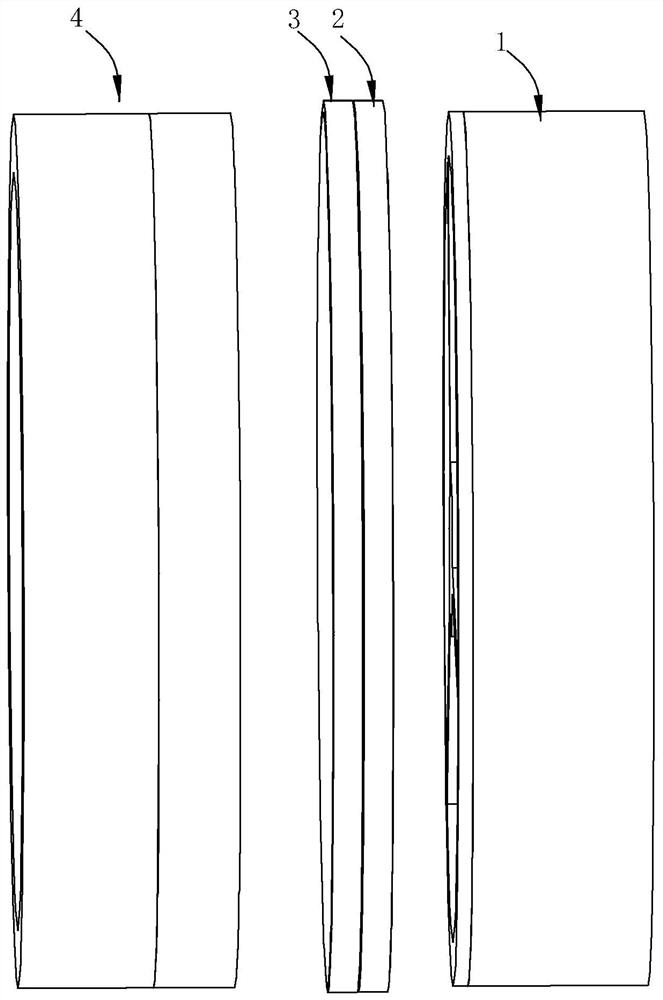

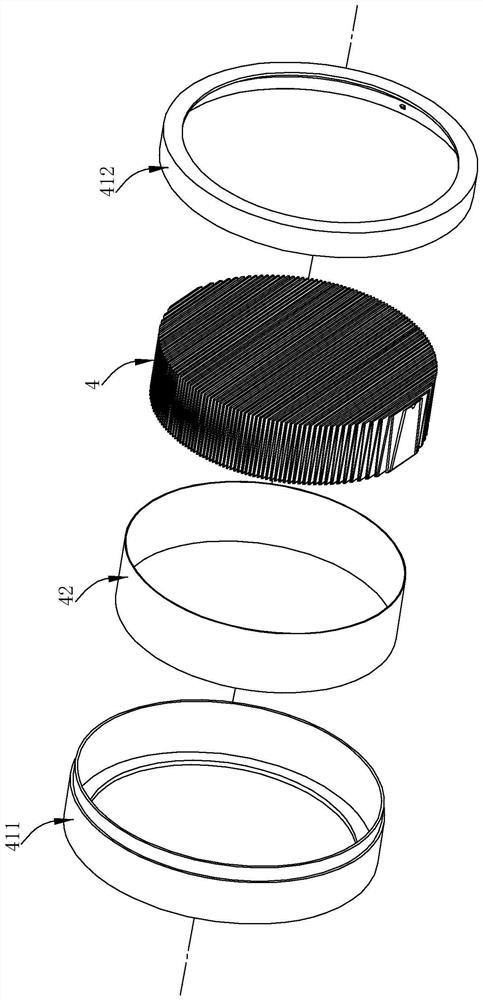

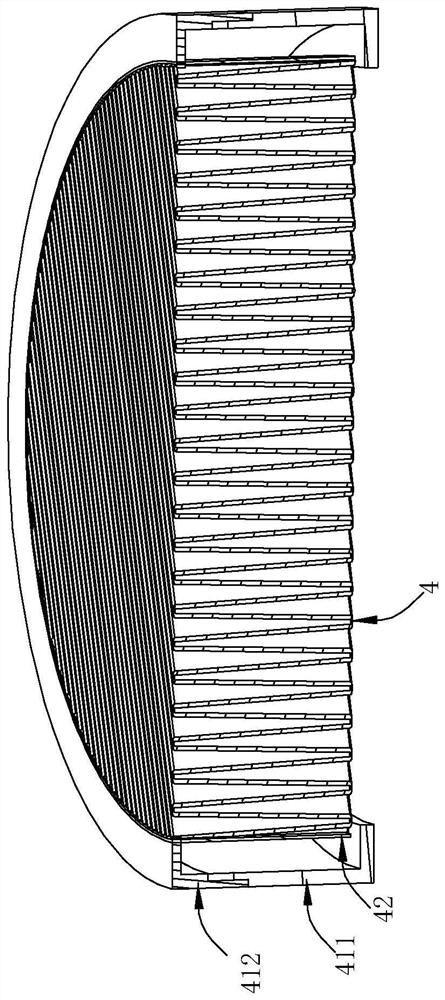

[0054] Such as Figure 1-10 As shown, the filter device of this preferred embodiment includes a humidifying component 1 , an anion generating component 2 , a dehumidifying component 3 and a filter screen 4 arranged in sequence along the air flow direction.

[0055] Such as figure 1 As shown, there is a distance of 5 cm between the humidifying component 1 and the negative ion generating component 2, such as Figure 5-9 As shown, the humidifying assembly 1 includes a frame body 11, a central shaft 12, an atomizing mechanism 13, and an extension arm 14. The frame body 11 is annular, and the frame body 11 allows airflow to pass through the area surrounded by it. The inside of the frame body 11 is hollow. A circle of chambers 111 is formed inside the frame body 11 .

[0056] The axis of the central shaft 12 extends vertically. The central shaft 12 is located in the area surrounded by the frame body 11 . The interior of the central shaft 12 is hollow to form an accommodating cavit...

Embodiment 2

[0073] The difference between embodiment 2 and embodiment 1 is that the preparation method of filter screen (4) is different:

[0074] In the present embodiment, the preparation method of filter screen (4) comprises the following steps:

[0075](1) 15g chitosan is added in 83g organic solvent dimethylacetamide (DMAC), then add 2g lithium chloride, stir evenly at 60 ℃, be mixed with the spinning solution of solid content 17wt% concentration, spinning The viscosity of the liquid is 1360mPa·s;

[0076] (2) After cooling the spinning solution for 12 hours, put it into the needle tube, carry out electrospinning on the spinning solution, use the non-woven fabric as the collection base fabric, and obtain the nanofiber layer accumulated on the non-woven fabric, the non-woven fabric and the nanofiber The fiber layers jointly constitute the filter screen (4); the electrospinning method is as follows: adjusting the spinning parameters to 14KV, the distance between the electrode wire and...

Embodiment 3

[0079] The difference between embodiment 3 and embodiment 1 is that the preparation method of filter screen (4) is different:

[0080] In the present embodiment, the preparation method of filter screen (4) comprises the following steps:

[0081] (1) Add 9g of chitin, 11g of chitosan and 2g of polyvinyl alcohol into 76mL of trifluoroacetic acid (TFA), then add 2g of lithium chloride, stir evenly at 60°C, and prepare a spinning solution with a solid content of 24%. Silk solution, the viscosity of spinning solution is 1890mPa·s;

[0082] (2) After cooling the spinning solution for 12 hours, put it into the needle tube, carry out electrospinning on the spinning solution, use the non-woven fabric as the collection base fabric, and obtain the nanofiber layer accumulated on the non-woven fabric, the non-woven fabric and the nanofiber The fiber layers jointly constitute the filter screen (4); the electrospinning method is as follows: the spinning parameter is 21KV, the distance betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com