Power-off protection device for 3D printer

A technology of power-off protection device and 3D printer, which is applied in the direction of emergency protection circuit device, circuit device, battery circuit device, etc., and can solve problems such as defects, defective products, and short life of printed models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

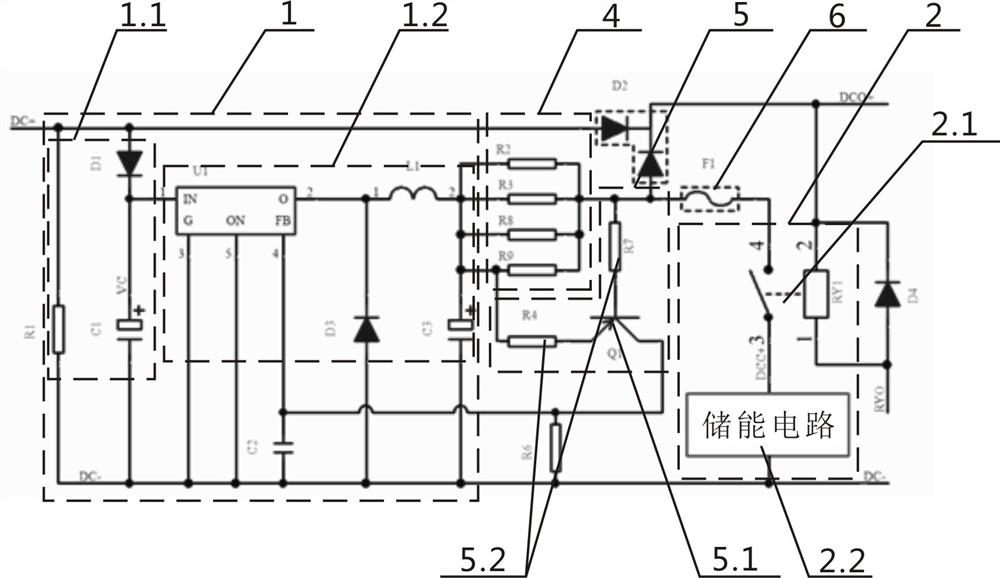

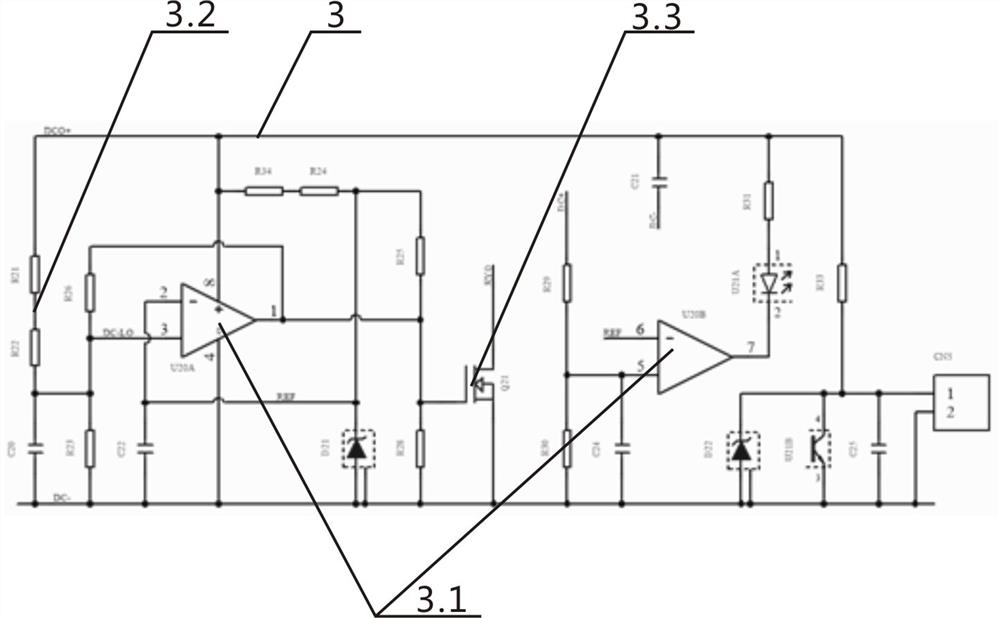

[0034] combined with Figure 1-2 The described power-off protection device for 3D printers includes a step-down and current-stabilizing module 1, an energy storage module 2 and a voltage comparison detection module 3;

[0035] The step-down and current-stabilizing module 1 can step down and stabilize the power supply, so that the maximum voltage of the energy storage circuit 2.2 is lower than the rated voltage of the power supply, and the charging state of the energy storage circuit 2.2 is constant current charging, step-down The current stabilizing module 1 is connected to the energy storage module 2, and the charging current of the energy storage module 2 is ≈0.5A, that is, the charging power increases linearly from 0W-12W, so as not to affect the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com