Application of a polyester amide as a high temperature resistant heat shrinkable film

A heat-shrinkable film and polyester amide technology, which is applied in the application field of polyester amide as a heat-shrinkable film, can solve the problems of poor heat resistance of heat-shrinkable films and achieve the effect of shrinkage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of heat-shrinkable film 1 specifically comprises the following steps:

[0048] Take 22.4g of tall oil-based dimer acid, 3.4g of 1,3-diamino-2-propanol, and 40mg of sodium phosphite into a three-necked flask, mix them uniformly with a mechanical stirrer under a nitrogen atmosphere at 80°C and heat them for 1 hour, then raise the temperature to 140 °C for 12 hours, then raised the temperature to 180 °C for 6 hours, then raised the temperature to 230 °C for 2 hours, and finally cooled the reaction system to 140 °C. After the reaction, the product was named polyester amide 1.

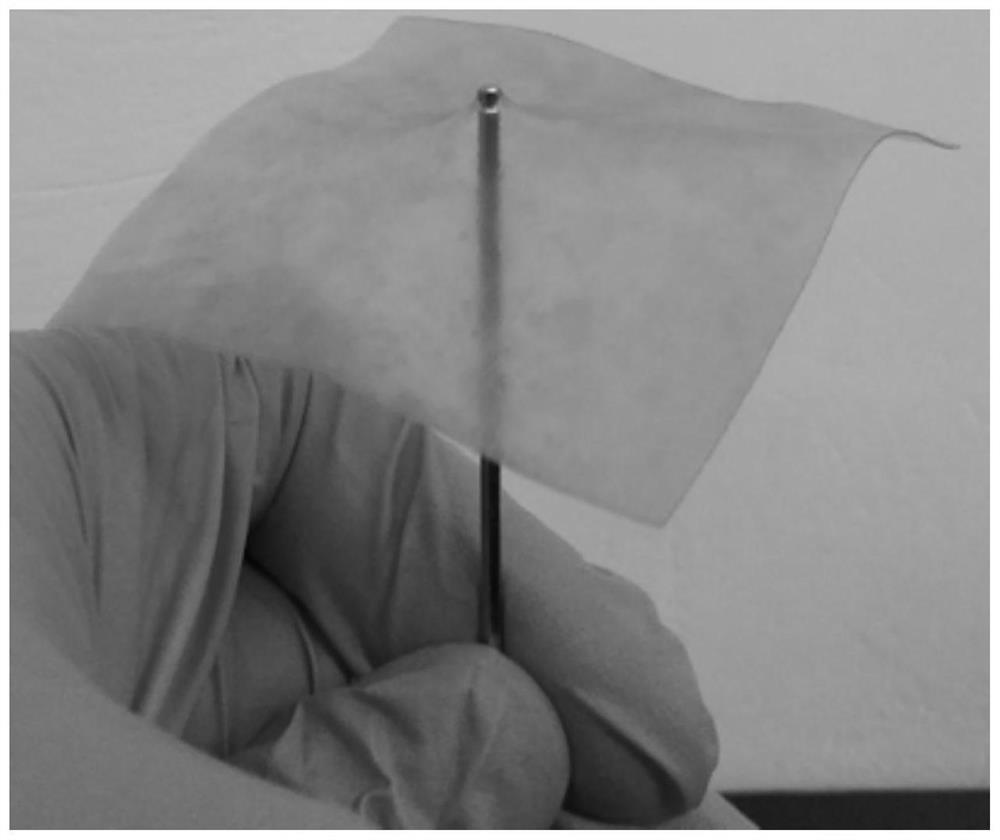

[0049] The polyester amide 1 was subjected to sheeting and uniaxial stretching, the stretching speed was 10 mm / min, the stretching strain was 150%, and the stretched product was named heat-shrinkable film 1.

Embodiment 2

[0051] The preparation of heat-shrinkable film 2 specifically comprises the following steps:

[0052]Take 20.8g of tall oil-based dimer acid, 3.4g of 1,3 diamino-2-propanol, and 40mg of sodium phosphite into a three-necked flask, mix them uniformly with a mechanical stirrer under a nitrogen atmosphere at 80°C and heat them for 1 hour, then raise the temperature to 140 °C for 12 hours, then raised the temperature to 180 °C for 6 hours, then raised the temperature to 230 °C for 2 hours, and finally cooled the reaction system to 140 °C. After the reaction, the product was named polyester amide 2.

[0053] The polyester amide 2 was subjected to sheeting and uniaxial stretching, the stretching speed was 10 mm / min, the stretching strain was 150%, and the stretched product was named heat-shrinkable film 2.

Embodiment 3

[0055] The preparation of heat-shrinkable film 3 specifically comprises the following steps:

[0056] Take 19.2g of tall oil-based dimer acid, 3.4g of 1,3 diamino-2-propanol, and 40mg of sodium phosphite into a three-necked flask, mix them uniformly with a mechanical stirrer under a nitrogen atmosphere at 80°C and heat for 1 hour, then raise the temperature to 140 °C for 12 hours, then raised the temperature to 180 °C for 6 hours, then raised the temperature to 230 °C for 2 hours, and finally cooled the reaction system to 140 °C. After the reaction, the product was named polyester amide 3.

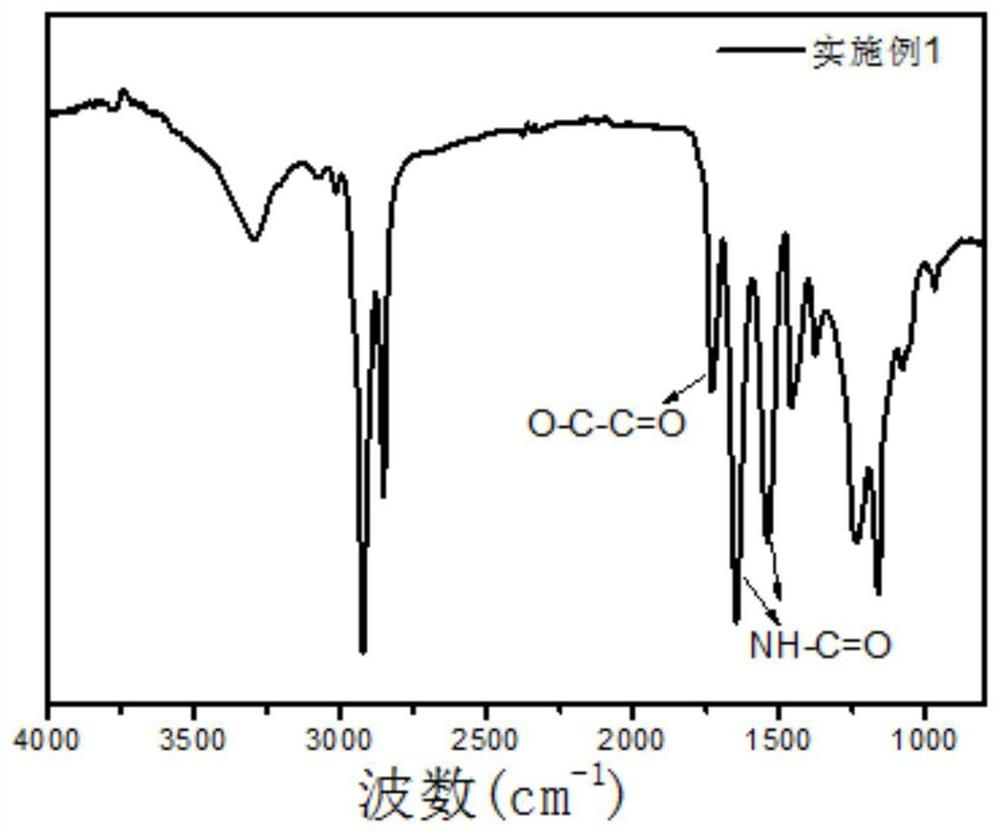

[0057] The polyester amide 3 was subjected to sheeting and uniaxial stretching, the stretching speed was 10 mm / min, the stretching strain was 150%, and the stretched product was named heat-shrinkable film 3 . Such as figure 1 Shown: After the raw material tall oil-based dimer acid of the present invention is reacted according to Example 1, the carboxyl peak basically disappears, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| tensile strain | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com