a zn doped vo 2 Powder and method for preparing composite film by using the powder

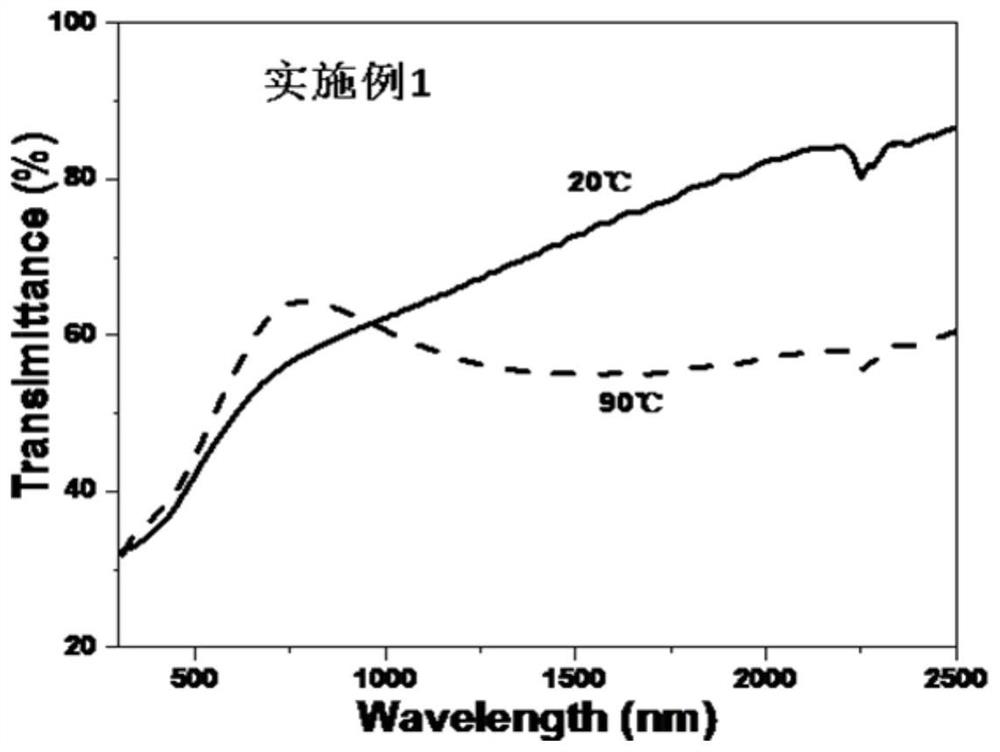

A composite film, VO2 technology, applied in the direction of coating, vanadium oxide, etc., can solve the problem of visible light transmittance reduction, etc., to achieve good thermally induced phase change visible light antireflection, visible light transmittance increase, good thermally induced phase change characteristic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

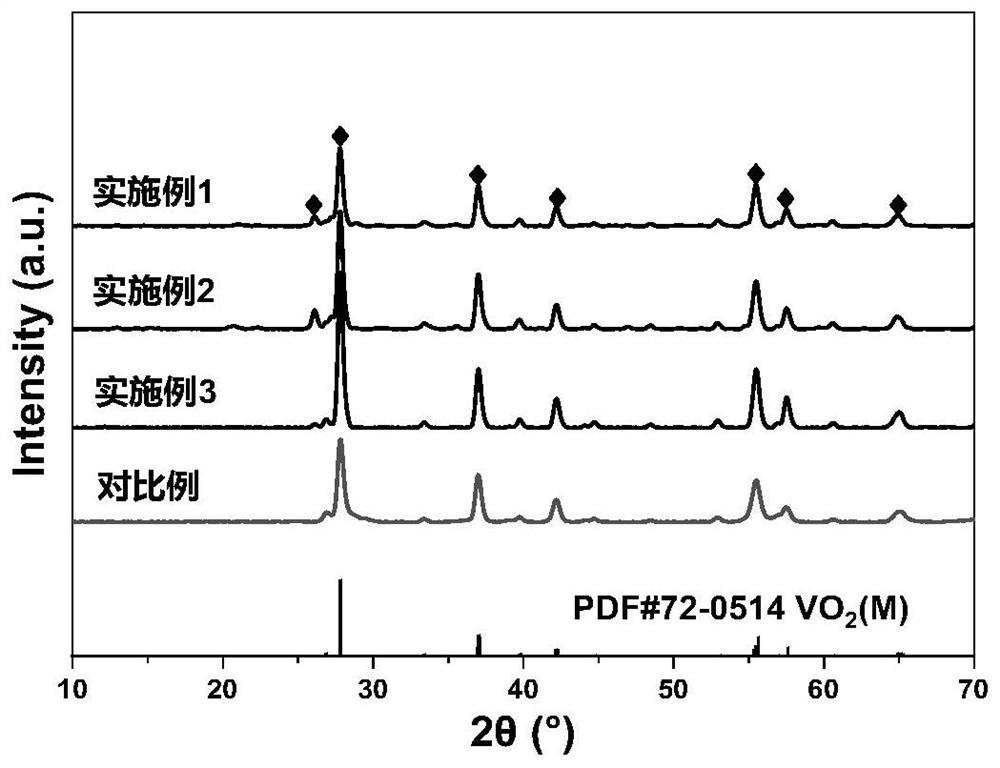

[0047] (1) Zn 0.16 VO 2 Powder preparation: 3.64 g of vanadium pentoxide and 5.0428 g of oxalic acid dihydrate were dispersed in 100 mL of deionized water, and 1.4048 g of zinc acetate dihydrate was added to obtain a reaction precursor solution; the reaction precursor solution was reacted at 240 ° C for 10 hours, and the The reacted precipitate was washed with water and alcohol in turn, filtered with vacuum suction, and dried at 60°C for 12 hours; then placed in N 2 After heat treatment at 680 °C for 3 hours under protection, Zn was obtained 0.16 VO 2 powder.

[0048] (2) Zn 0.16 VO 2 Thin film preparation: take 0.4g Zn 0.16 VO 2 To the powder, add 10 mL of anhydrous ethanol, and after ball-milling dispersion treatment, extract 5 mL of ball-milling fluid, mix with 20 mL of anhydrous ethanol and 12.5 mL of polyurethane resin, and mix for 20 minutes to obtain a coating liquid, which is uniformly coated on the powder by roller coating. glass substrate surface to obtain Zn...

Embodiment 2

[0051] (1) Zn 0.08 VO 2 Powder preparation: 3.64 g of vanadium pentoxide and 5.0428 g of oxalic acid dihydrate were dispersed in 100 mL of deionized water, and 0.7024 g of zinc acetate dihydrate was added to obtain a reaction precursor solution; the reaction precursor solution was reacted at 240 ° C for 10 hours, The reacted precipitate was washed with water and alcohol in turn, filtered with vacuum suction, and dried at 60°C for 12 hours; then placed in N 2 After heat treatment at 680 °C for 3 hours under protection, Zn was obtained 0.08 VO 2 powder.

[0052] (2) Zn 0.08 VO 2 Thin film preparation: take 0.4gZn 0.08 VO 2 To the powder, add 10 mL of anhydrous ethanol, and after ball-milling dispersion treatment, extract 5 mL of ball-milling fluid, mix with 20 mL of anhydrous ethanol and 12.5 mL of polyurethane, and mix and stir for 20 minutes to obtain a coating liquid. surface of the glass slide to obtain Zn 0.08 VO 2 composite film.

[0053] The test results show t...

Embodiment 3

[0055] (1) Zn 0.02 VO 2 Powder preparation: 3.64 g of vanadium pentoxide and 5.0428 g of oxalic acid dihydrate were dispersed in 100 mL of deionized water, and 0.1756 g of zinc acetate dihydrate was added to obtain a reaction precursor solution; the reaction precursor solution was reacted at 240 ° C for 10 hours, The reacted precipitate was washed with water and alcohol in turn, filtered with vacuum suction, and dried at 60°C for 12 hours; then placed in N 2 After heat treatment at 680 °C for 3 h under protection, Zn-doped VO was obtained 2 powder.

[0056] (2) Zn 0.02 VO 2 Film preparation: the same as step (2) in Example 1.

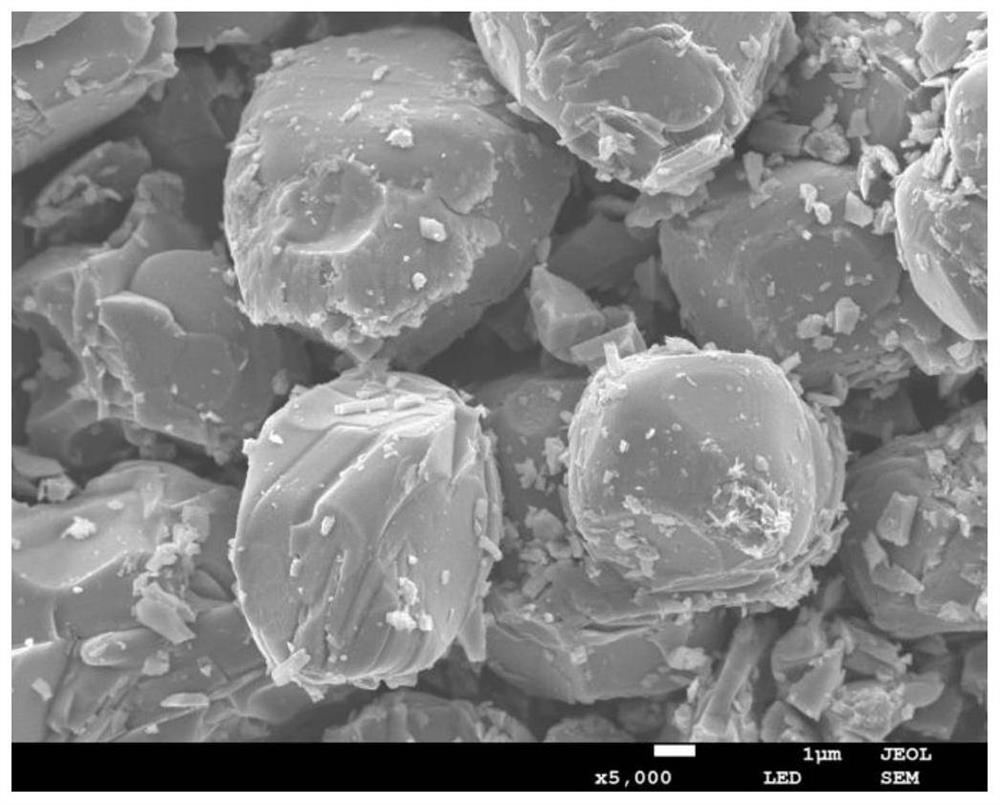

[0057] The test results show that the Zn prepared by the above method 0.02 VO 2The crystal structure of the powder is M-phase VO 2 , the particles are approximately spherical large particles with a rough surface and a diameter of 5-10 μm, and some small particles are attached to the surface of the spherical large particles, Zn 0.08 VO 2 Powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com