Method for synthesizing low-nitrogen high-purity silicon carbide powder

A high-purity silicon carbide and powder technology, which is applied in the fields of carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem that the growth requirements of high-purity semi-insulating silicon carbide single crystals cannot be met, and the nitrogen content is high and difficult to escape. Graphite crucible and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail in combination with the embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. The technical solutions of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the scope of protection is not limited thereto.

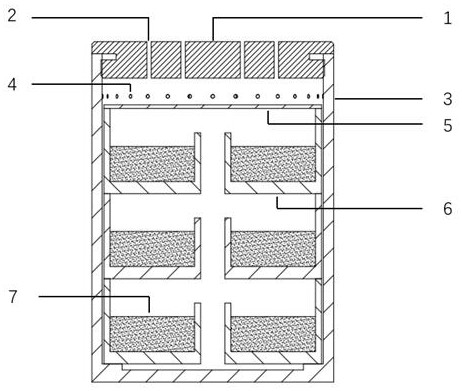

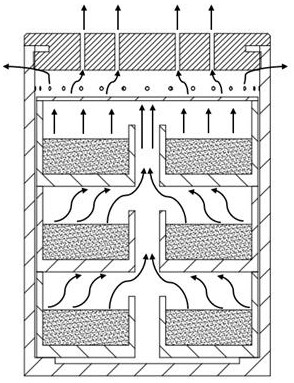

[0025] This embodiment provides a new silicon carbide powder synthesis assembly scheme, such as figure 1 Shown: is a crucible for the synthesis of silicon carbide powder, the crucible includes an isostatic graphite crucible 3 and six hollow circular structures of isostatic graphite arranged in the isostatic graphite crucible 3 The small crucible 6, the crucible lid 1 of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com