Vertical Active Lime Calciner

A technology of active lime and calciner, applied in the field of vertical active lime calciner and lime shaft kiln, can solve the problems of energy loss and environmental pollution, high production cost, difficult to guarantee product quality, etc., and achieve smooth continuous feeding. , The quality of calcined products is stable, and the effect of reducing the height of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

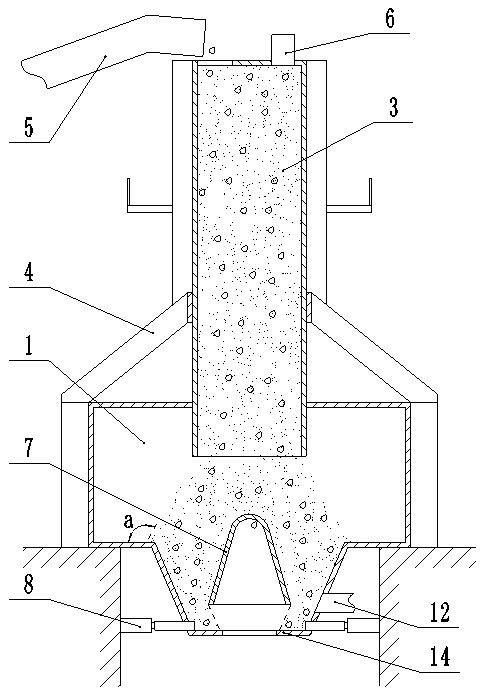

[0031] Such as figure 1 , Figure 4-7 As shown, the vertical active lime calciner includes an outer combustion chamber 1, a fuel injection pipeline 2, a kiln body 3, a suspension 4, a conveyor belt 5, a negative pressure induced fan 6, a hydraulic discharge device 8 and a control system. The structure of the chamber 1 is that the bottom of the cylindrical furnace body is provided with a funnel-shaped cooling section. The furnace body of the outer combustion chamber 1 is fixedly installed on the ground and its cooling section is located in the pit. The fuel injection pipeline 2, the kiln body 3 is fixedly arranged above the outer combustion chamber 1 through the suspension bracket 4, the kiln body 3 is a cylindrical shape with an open lower end and its lower end extends into the interior of the furnace body, and the upper wall of the furnace body Sealed connection with the outer wall of the kiln body 3, the top of the kiln body 3 is provided with a feed port and the discharge ...

Embodiment 2

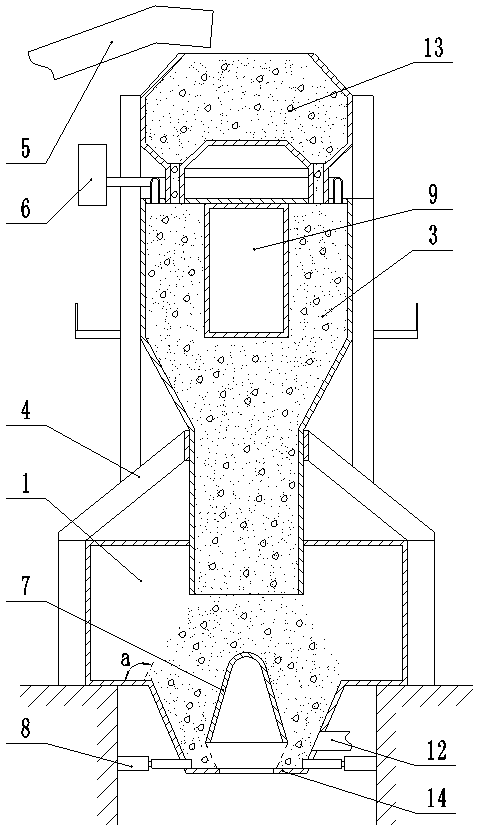

[0038] Such as figure 2 As shown, on the basis of Example 1, the upper part of the kiln body 3 is a preheating section and the lower part is a calcining section, the diameter of the preheating section is larger than the calcining section, and the preheating section and the calcining section pass through Conical transition seal connection.

[0039] A hollow cylinder 9 is fixed in the center of the preheating section of the kiln body 3 .

[0040] Above the kiln body 3, there is a process silo 13, the lower part of the process silo 13 communicates with the upper part of the kiln body 3 through an annular pipe and supplies materials to the kiln body 3, and the discharge end of the conveyor belt 5 corresponds to the process material Storehouse 13 feeding ports.

[0041] The inner bottom surface of the process silo 13 is provided with a conical protrusion, and the annular pipe communicating with the upper part of the kiln body 3 is arranged at the lowest point around the conical ...

Embodiment 3

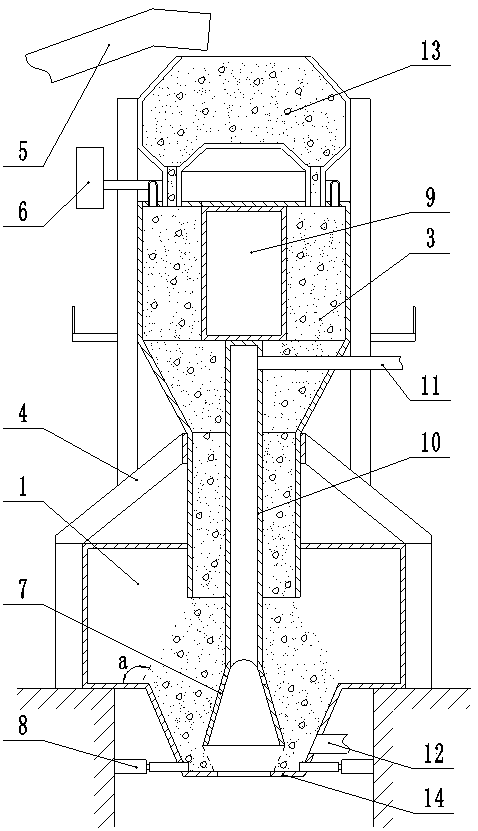

[0045] Such as image 3 As shown, on the basis of Embodiment 2, a cylindrical inner combustion chamber 10 is vertically arranged in the center of the kiln body 3 and the lower end of the inner combustion chamber 10 is open, and the upper part of the inner combustion chamber 10 communicates with Internal combustion pipeline 11 is arranged.

[0046] The lower end of the internal combustion chamber 10 communicates with the inside of the material retaining platform 7 and the side wall of the material retaining platform 7 is evenly provided with a plurality of air outlet holes, so that the combustion fuel in the internal combustion chamber 10 can evenly overflow.

[0047] This embodiment is suitable for large-scale calcination with a large diameter kiln body, double-stage combined calcination, to avoid incomplete calcination at the center of the kiln body, which affects product quality, and the working process is similar to the second embodiment, but the internal combustion pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com