A kind of integral sealed cabin and preparation method thereof

A technology of integral sealing and cabin body, which is applied in space navigation equipment, space navigation equipment, and space navigation vehicles, etc., and can solve the problems of long-term use and maintenance inconvenience of the structure, increase of structural weight and cost, hidden danger of leakage of assembly connection holes, etc. , to achieve the effects of repeated use and maintenance, improved maintainability, and reduced assembly workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides the preparation method of the integral sealed cabin described in the above technical solution, comprising the following steps:

[0045] Lay the prepreg at the position of the longitudinal stiffener of the mandrel, and fill the cavity of the longitudinal stiffener with the second foam; Filling the cavity with the first foam; then laying the outer skin with the first fiber fabric to obtain a preform;

[0046] Using resin transfer molding method to inject resin into the preform, after curing and demoulding, the capsule is obtained;

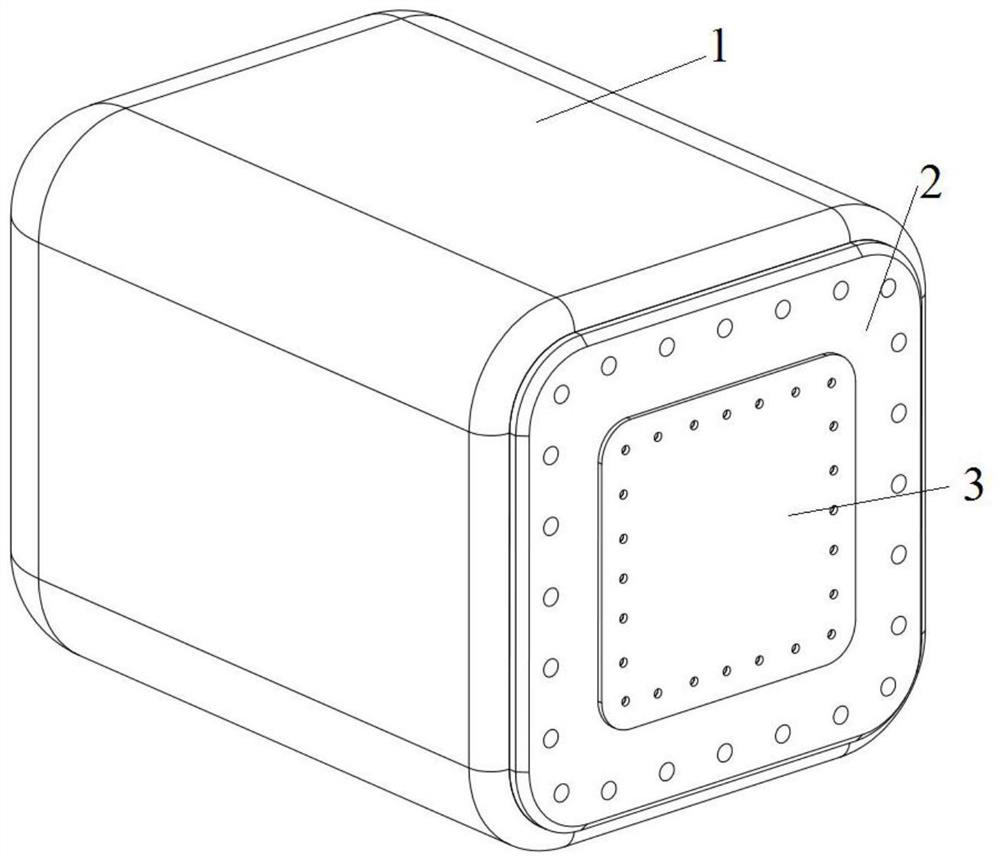

[0047] Holes are made at specified positions of the rear end flanging of the cabin body, and are connected with the metal rear end cover by bolts; the maintenance port cover and the metal rear end cover are connected by bolts to obtain an integrally sealed cabin.

[0048] In the present invention, prepreg is spread at the position of the longitudinal reinforcing rib of the core mold, and the second foam is ...

Embodiment 1

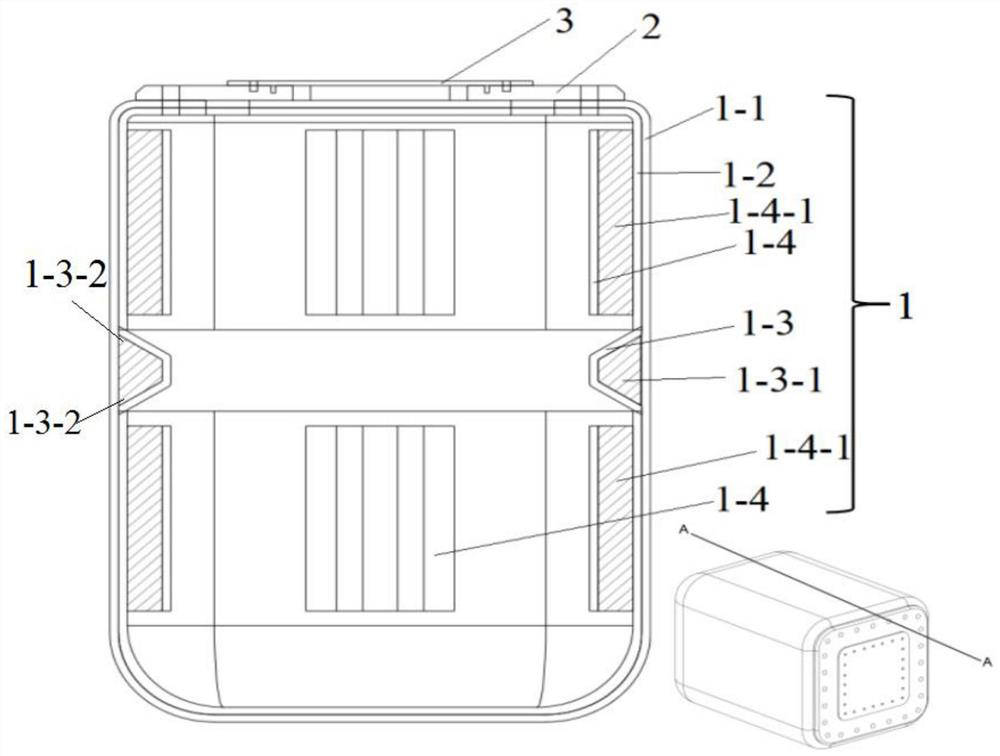

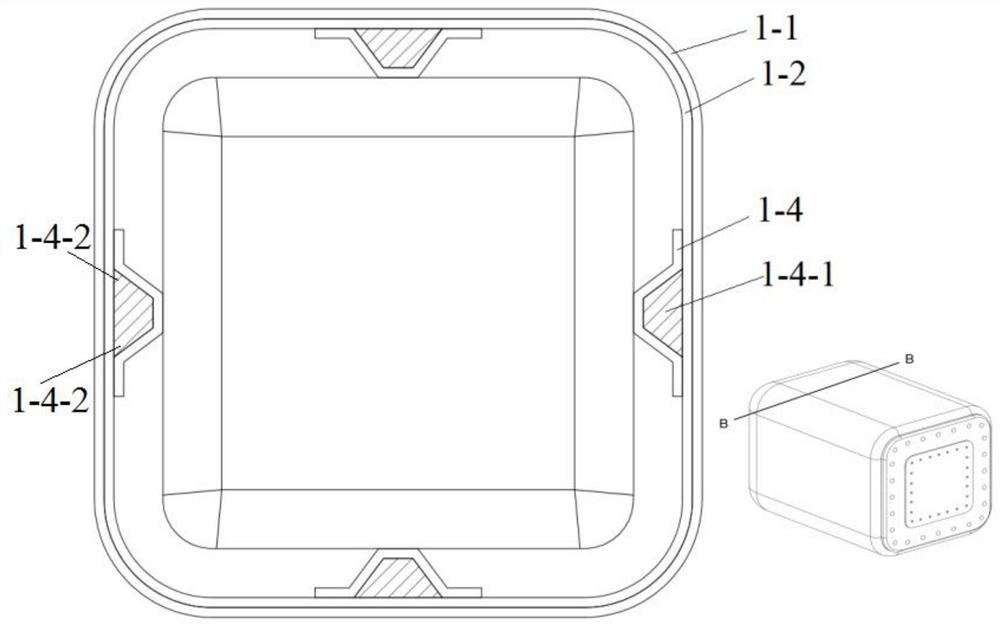

[0069] Integral sealed cabin: the total thickness of the cabin is 5mm, of which: the inner skin is 2mm and the outer skin is 3mm; the size of the cabin is 400mm×400mm×600mm.

[0070] The annular reinforcing rib is located in the middle of the interior length direction of the cabin;

[0071] The longitudinal reinforcing ribs are arranged in the middle of the four inner sides of the cabin; and there are two longitudinal reinforcing ribs located on the same inner side of the cabin, which are divided into two sides of the annular reinforcing ribs; the annular reinforcing ribs The parameters of the Ω-type annular stiffener and the Ω-type longitudinal stiffener include: thickness 2mm, trapezoidal section upper bottom 20mm, bottom bottom 30mm, height 15mm; longitudinal stiffener width 80mm, length 240mm .

[0072] The depth of the sealing groove of the metal rear end cap is 4.9mm and the width is 7.4mm;

[0073] The size of the metal rear end cap is 360mm×360mm;

[0074] The size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com