Rubber sealing element forming die

A technology for rubber seals and forming molds, which is applied to household components, household appliances, and other household appliances, and can solve the problems of poor quality and effect of rubber molding shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

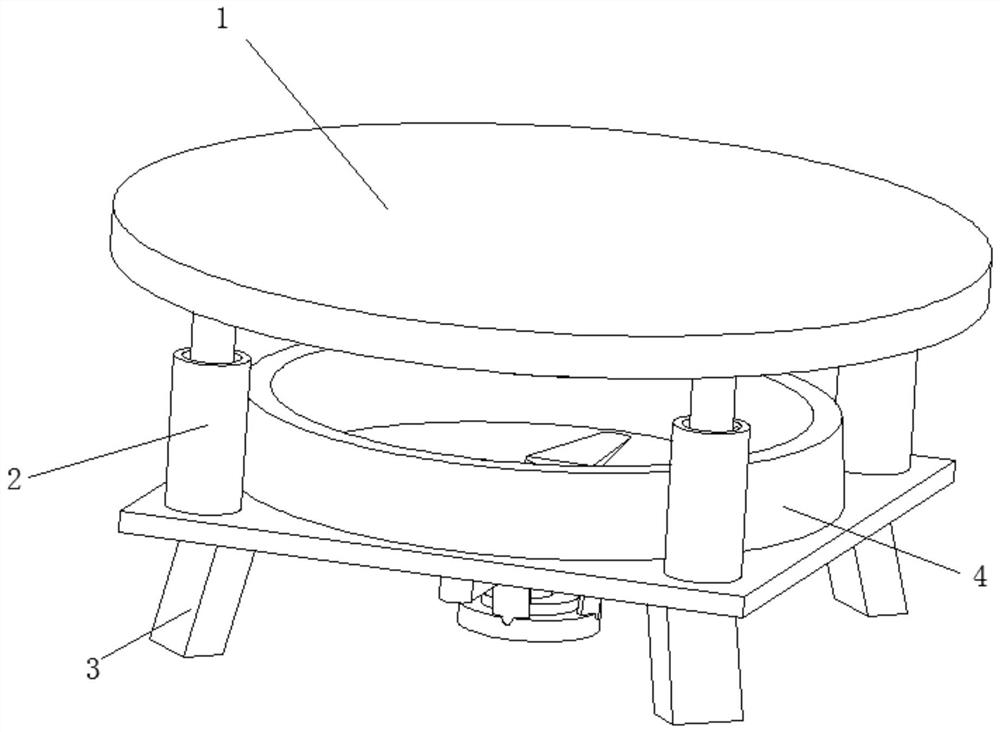

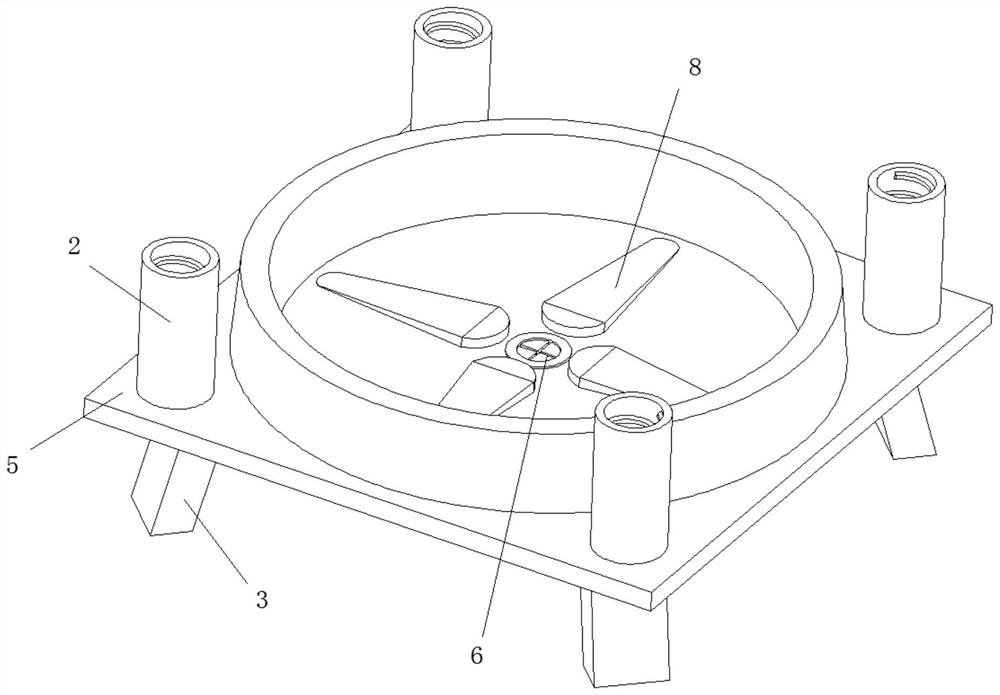

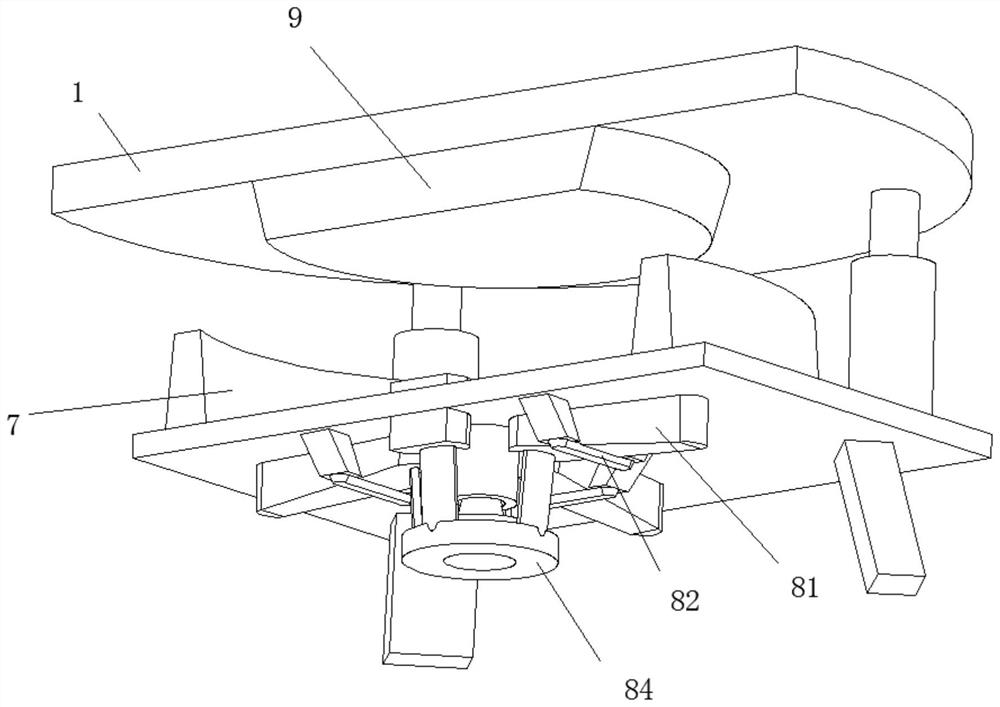

[0036] Such as Figure 1-4 As shown, the present invention provides a technical solution: a mold for forming rubber seals, including an upper pressure mold 1, the side of the lower surface of the upper pressure mold 1 is fixedly connected with an elastic damper 2, and the lower surface of the upper pressure mold 1 The middle of the surface is fixedly connected with a lower pressure block 9, the bottom end of the elastic damper 2 is fixedly connected with a supporting horizontal plate 5, and the bottom of the supporting horizontal plate 5 is fixedly connected with a supporting foot 3, and the bottom of the supporting horizontal plate 5 The upper surface is fixedly connected with the mold wall 4, the middle of the upper surface of the supporting horizontal plate 5 is provided with an anti-adhesive device 8, and the axial center of the upper surface of the supporting horizontal plate 5 is fixedly connected with a detection device 6, and the anti-adhesive The device height of devi...

Embodiment 2

[0044] Such as Figure 5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the detection device 6 includes a detection cylinder 61, and the outer surface of the detection cylinder 61 is fixedly connected to the axis of the support horizontal plate 5 , the top of the inner cavity of the detection cylinder 61 is fixedly connected with an elastic baffle 64, and the upper surface of the elastic baffle 64 is at the same height as the upper surface of the supporting horizontal plate 5, and the opposite surfaces of the elastic baffle 64 are respectively The second cutout 66 and the first cutout 65 are fixedly connected, and the first cutout 65 is arranged at the axis between the opposite surfaces of the elastic baffle 64 . In the demoulding process, the second cutting block 66 and the first cutting block 65 can extrude and cut off the overflowing excess rubber after molding, so that the surface of the rubber injection molded part is smoother...

Embodiment 3

[0049] Such as Figure 6-8 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the blocking device 83 includes a bottom plate 832, and the bottom of the bottom plate 832 is fixedly connected to the axis of the upper surface of the operation plate 84 , the top of the bottom plate 832 is fixedly connected with a cone shell 831, the outer surface of the cone shell 831 is fixedly connected with a rotating shaft 834, and the outer surface of the rotating shaft 834 is rotatably connected with a pressure plate 835, and the bottom of the pressure plate 835 The first spring 833 is fixedly connected to the outer surface of the cone shell 831 .

[0050] The middle of the upper surface of the bottom plate 832 is fixedly connected with a second spring 837, the top of the second spring 837 is fixedly connected with a top block 836, and the outer surface of the cone shell 831 is slidably connected with a locking device 838, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com