Extrusion grinding device for herbaceous plant solid particle beverage

A technology of solid particles and herbal plants, applied in application, grain processing, food science, etc., can solve the problems of uneven grinding particles and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

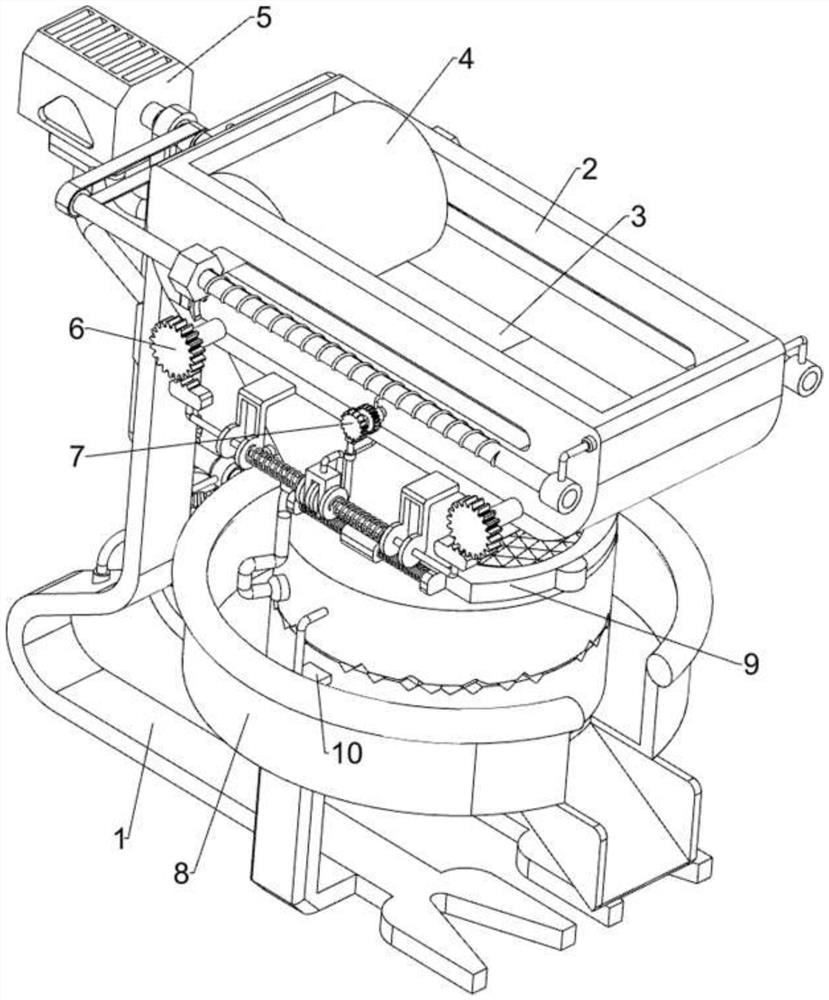

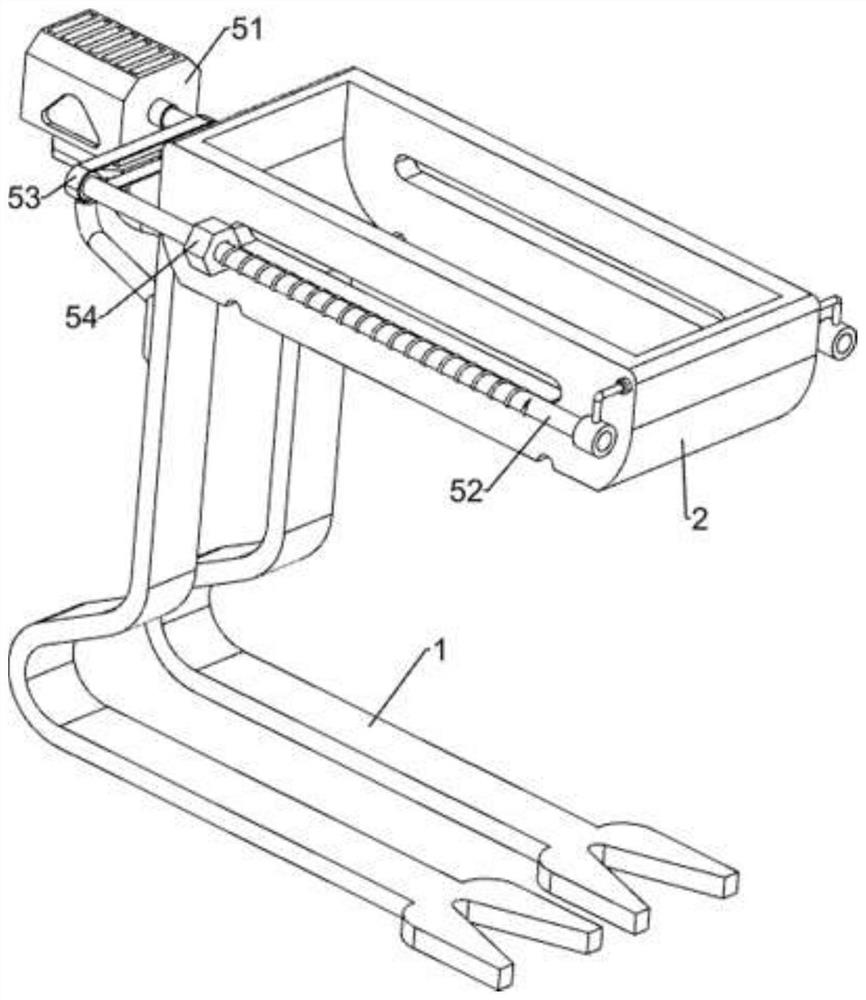

[0027] A kind of extrusion milling device for herbal plant solid particle beverage, such as Figure 1-3 As shown, it includes a bracket 1, a hopper 2, a baffle plate 3, a roller 4, an automatic rolling assembly 5, and a blanking assembly 6. The upper side of the bracket 1 is provided with a hopper 2, and the left and right sides of the bottom of the hopper 2 are rotating. A baffle plate 3 is provided, a sliding roller 4 is provided on the hopper 2, an automatic rolling assembly 5 is provided between the bracket 1 and the left side of the hopper 2, and a blanking assembly 6 is provided on the hopper 2.

[0028] When the herb solid particles need to be extruded and milled, the herb solid particles are placed in the hopper 2, the herb solid particles will be blocked by the baffle plate 3, and then the automatic rolling assembly 5 is controlled to operate, thereby making the roller 4 Move to squeeze and grind the herbaceous plant solid particles in the hopper 2. After the herbaceo...

Embodiment 2

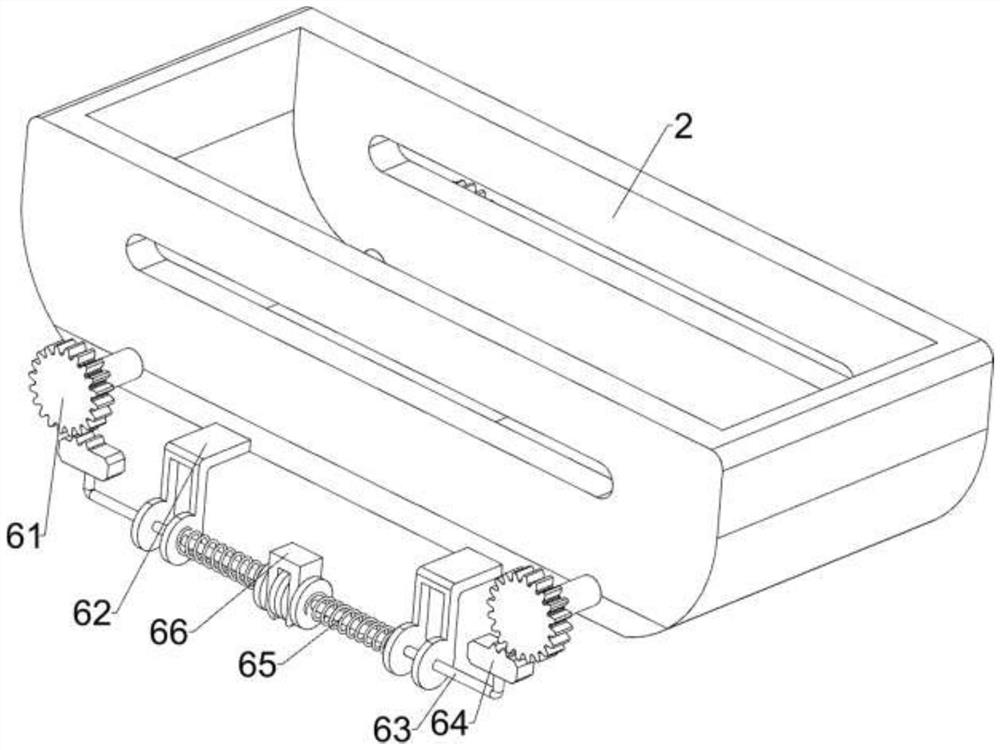

[0034] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the automatic opening assembly 7 is also included. The automatic opening assembly 7 includes a ratchet 71, a second connecting rod 72, a second rack 73, a ratchet 74 and a second gear 75. There are ratchets 71, the upper side of the block 66 is connected with a second connecting rod 72, the second connecting rod 72 is slidingly connected with the hopper 2, the second connecting rod 72 is connected with a second rack 73, the hopper 2 Both front and rear sides are rotatably connected with a ratchet 74, and the ratchet 74 cooperates with the ratchet 71. The ratchet 74 is provided with a second gear 75, and the second gear 75 meshes with the second rack 73.

[0035]Starting the motor 51 will cause the nut 54 to move to the right first, thereby causing the ratchet 71 to move to the right, thereby contacting the ratchet 74, and then driving the ratchet 74 to rotate one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com