Metal workpiece pickling device for electronic product machining

A technology for metal workpieces and pickling devices, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as low efficiency, poor pickling effect, inadequate pickling, etc., to achieve pickling Comprehensive cleaning, less trouble, better pickling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

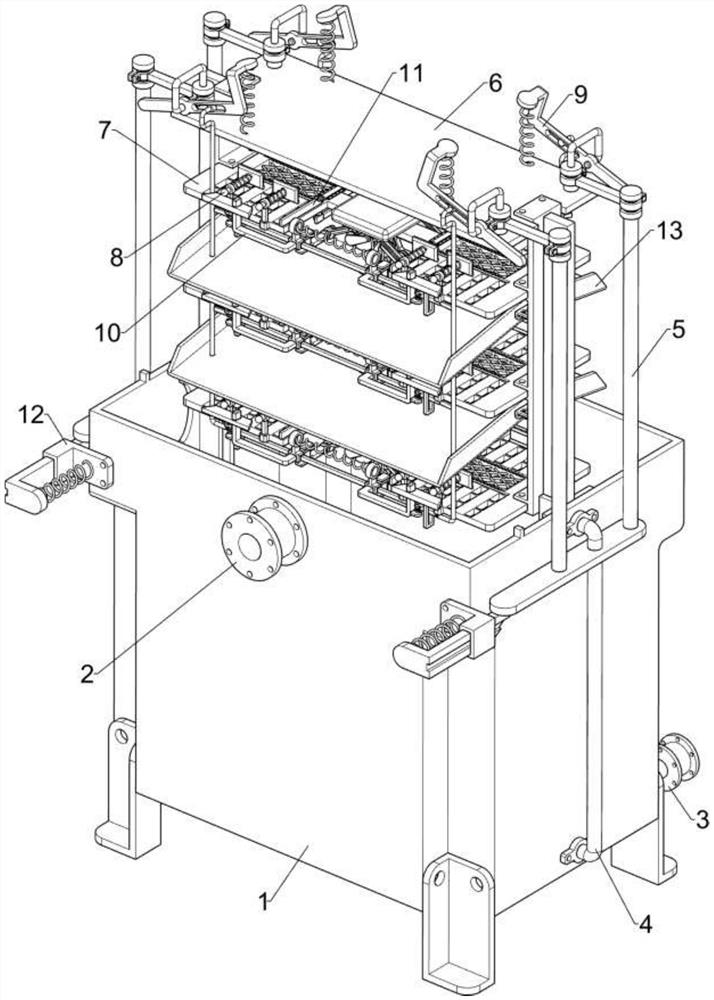

[0029] A metal workpiece pickling device for electronic product processing, such as figure 1 As shown, it includes a cleaning frame 1, a mounting cylinder 2, a drain pipe 3, a guide rod 4, a sliding frame 5, a mounting frame 6 and a placement plate 7. The upper front side of the cleaning frame 1 is provided with a mounting cylinder 2, and the cleaning frame 1 The bottom rear side of the cleaning frame 1 is provided with a drain pipe 3, and the left and right sides of the cleaning frame 1 are fixedly connected with a guide rod 4 by screws, and the guide rod 4 is slidably provided with a sliding frame 5, and a mounting frame is connected between the sliding frames 5 6. There are three placement plates 7 on the mounting frame 6 .

[0030] When it is necessary to pickle the electronic product, inject the pickling solution into the cleaning frame 1 through the installation cylinder 2, stop injecting the pickling solution into the installation cylinder 2 after filling, then place th...

Embodiment 2

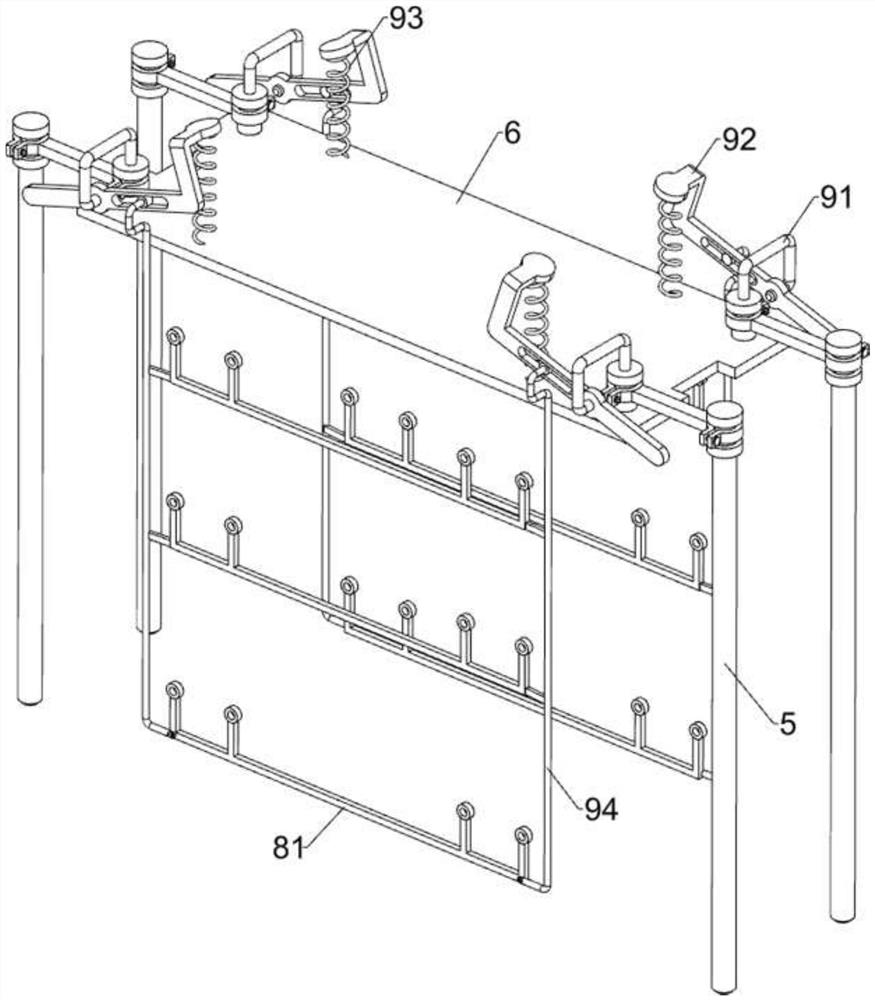

[0032] On the basis of Example 1, such as Figure 1-7 As shown, it also includes a limit assembly 8, the limit assembly 8 includes a sliding plate 81, a clamping plate 82 and a first spring 83, and the front and rear sides of the placement plate 7 are slidably provided with a sliding plate 81, and the sliding plate 81 slides Four splints 82 are provided in the formula, and first springs 83 are connected between the splints 82 and the sliding plate 81 .

[0033] When the electronic product needs to be pickled, the splint 82 can be controlled to move outward, the first spring 83 is compressed, and then the electronic product is placed between the splints 82, and then the splint 82 is no longer controlled, and the first spring 83 rebounds to drive The splint 82 moves to the inside and resets, thereby making the splint 82 limit the position of the electronic product, thereby preventing the electronic product from moving and contacting the cleaning frame 1 when moving, thereby caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com