Backflushing filtering system for BOPP film production line

A filtration system and production line technology, applied in filtration separation, moving filter element filters, separation methods, etc., can solve problems such as the need to regularly clean the filter cartridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

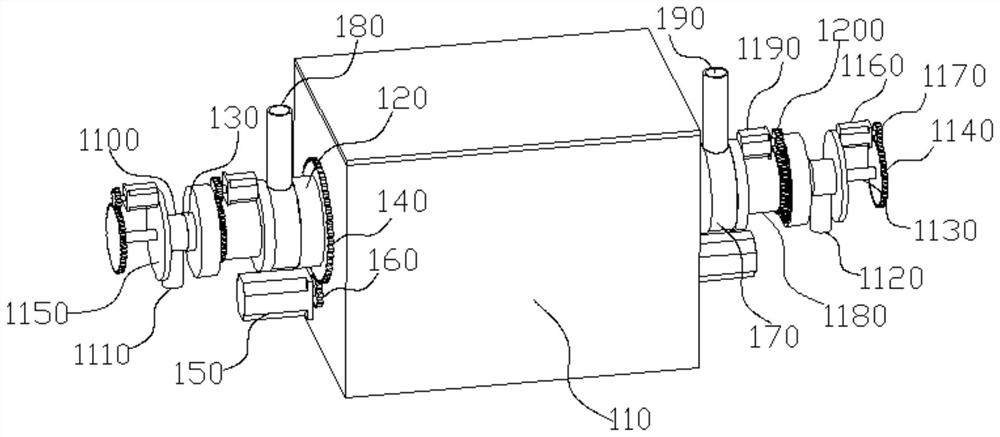

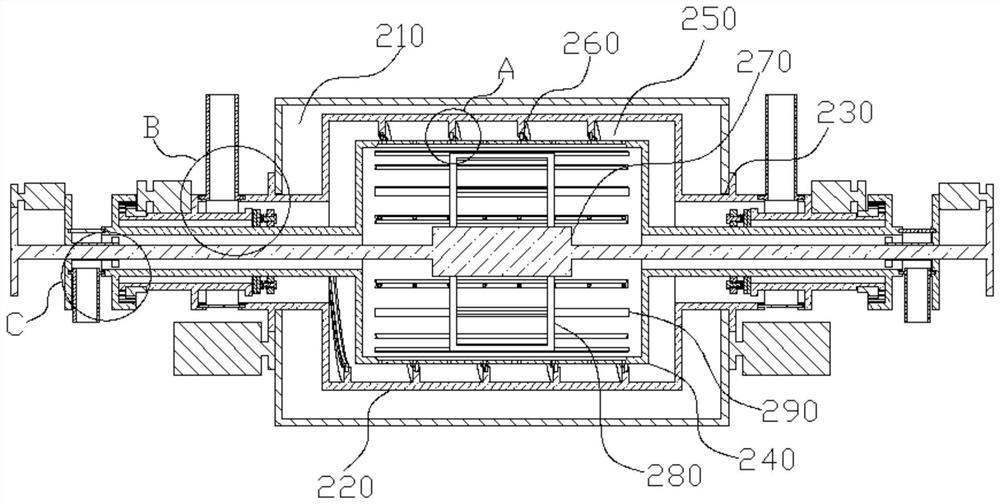

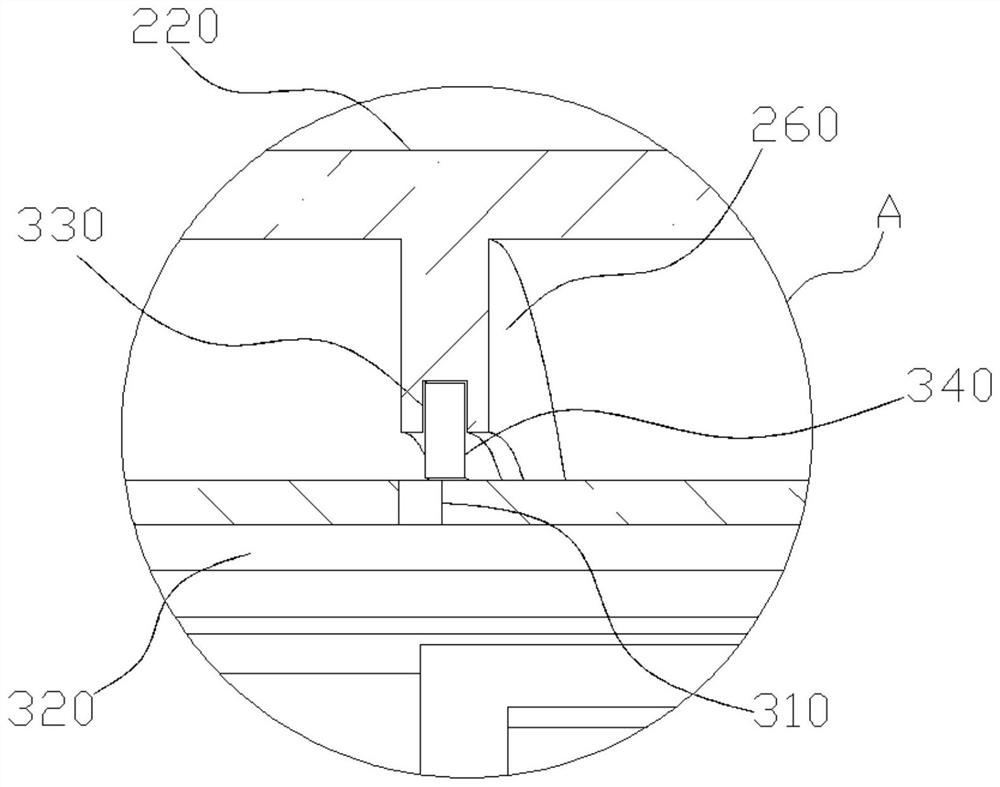

[0031] Such as Figure 1-6 As shown, the present embodiment provides a recoil filter system for a BOPP film production line, which includes a filter box 110, a filter mechanism installation cavity 210 is provided in the filter box 110, and a rotatable outer cylinder is provided in the filter mechanism installation cavity 210 220, the two ends of the filter box 110 along the axial direction of the outer cylinder 220 are provided with a filter box through hole 230, and the two ends of the outer cylinder 220 are provided with an outer cylinder water delivery pipe 120 matching with the filter box through hole 230; 220 is provided with a filter cartridge 240, and the filter cartridge 240 is provided with several filter holes 310 evenly distributed along its circumference, and the filter cartridge 240 is provided with a blocking mechanism for blocking the filter holes 310; the filter cartridge 240 Both ends are provided with a filter cartridge water delivery pipe 130; the outer cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com