Non-dairy cheese analogue and process for preparation thereof

An analogue, non-dairy technology, applied in the field of preparing cheese analogue compositions, natural non-dairy cheese analogue compositions, which can solve the problem of no cheese analogues for consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

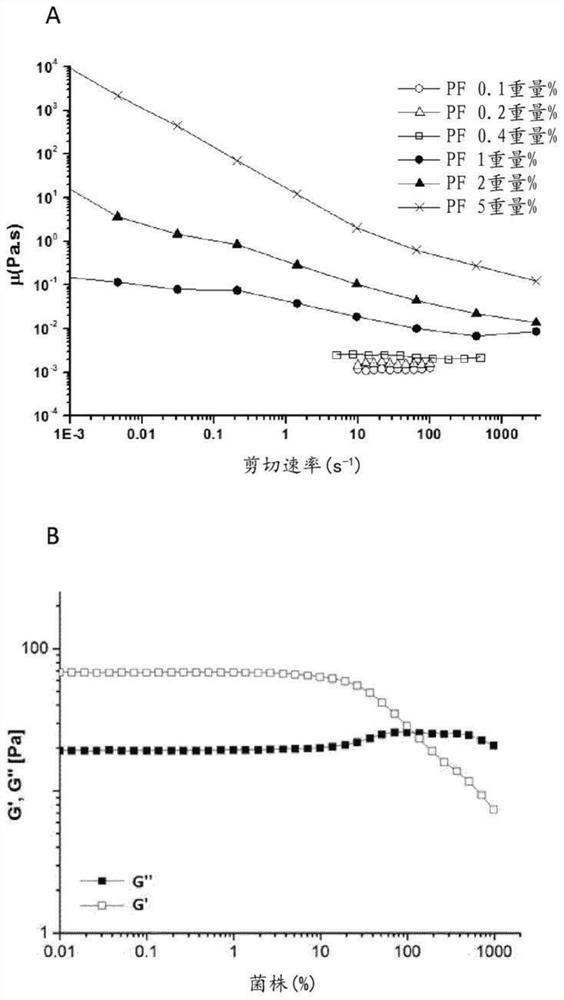

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

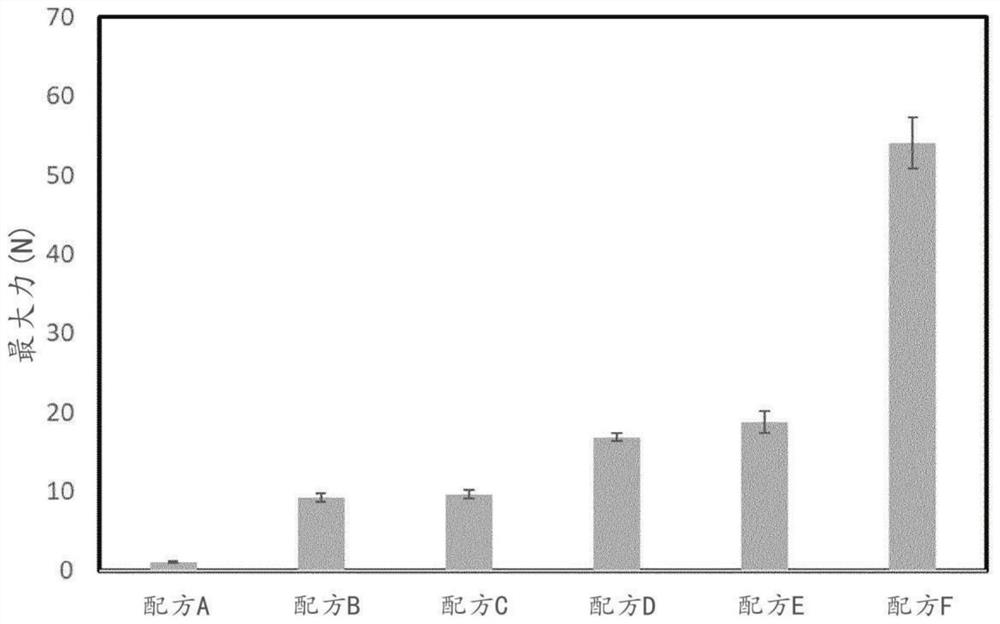

[0044] Example 1: Non-milk cheese analog composition

[0045] Non-milk cheese formula A to F (expressed in weight) is prepared in a different composition of laboratory scale outlined in Table 1. The total solid foundation shown in the table includes fibers, proteins, lipids (high oleic glycoliol - HOSO and milk fruit steeidity), calcium and salt.

[0046] Table 1 :

[0047] ingredient Formula A Formula B Formula C Formula D Formula e Formula f Potato fiber 0.5 4 5.4 5.6 8.9 5.6 Pea protein separation 11.5 12 10.6 10.4 7.1 6.4 Hoso 17 16.7 6.7 10 15 15 Milled fruit steeidity 0 3.3 3.3 5 0 15 Calcium phosphate 2 2 2 2 2 2 salt 0.5 0.5 0.5 0.5 0.5 0.5 Orange juice 3 3 3 3 3 3 water 65.5 58.5 68.5 63.5 63.5 52.5 Total solid 31.5 38.5 28.5 33.5 33.5 44.5 SFA (%) 1.4 3.4 2.6 3.9 1.2 10.5

Embodiment 2

[0048] Example 2: Production process of non-breast cheese

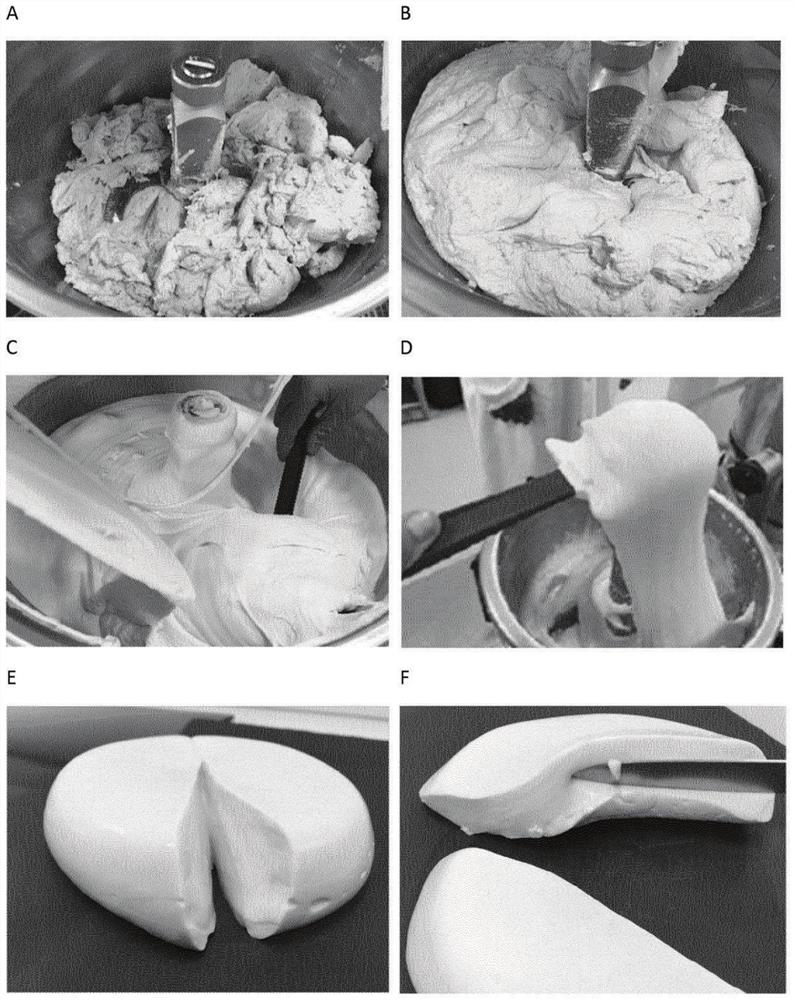

[0049] Different non-breast cheeses outlined in Table 1 are prepared using a two-clamping STEPHAN mixer with a laboratory scale of cutting blades. figure 2 A to figure 2 F shows that different steps of the preparation method include weighing and dry mixing of powder components. Add water and mix under high shear in the Stephan mixer (sample T = 20 ° C / T = 5-10 minutes) figure 2 A).

[0050] Next, a lipid is added under low shear (ie HOSO or laborate steeidity), and then adding acid orange juice under high shear mixing (sample T = 20 ° C / T = 10- 15 minutes) to obtain a dietary fiber-protein gel network with stable lipid droplets, obtained figure 2 B. The sample (sample T = 85 ° C) is then heated while mixing under high shear until the target stretching ability is reached, and the slide shape is smoothly figure 2 C and figure 2 D). Finally, molded samples (sample T> 70 ° C) were cooled until set (T = 4-10 ° C, preferab...

Embodiment 2a

[0051] Example 2A: Comparative example

[0052] The same method (Example 2) was used in the same method (Example 2), and a non-brev-made cheese was prepared using a dietary fiber from a pea source, wherein the insoluble fraction (70% by weight) increased, the concentration was the same as the embodiments mentioned in the present invention, as follows Top: 10% by weight pea shell fiber, 5% by weight pea protein, 20% by weight of lipid, 2% by weight of calcium phosphate and 1% by weight of orange juice. Cheese analogs cannot be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com