Element yield and thermal neutron count ratio combined porosity measurement method

A measurement method, thermal neutron technology, applied in the direction of measurement devices, geophysical measurement, nuclear radiation exploration, etc., can solve the problems of large deviation of neutron porosity measurement results, inaccurate qualitative interpretation conclusions of reservoirs, etc., to achieve Accurate calculation, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

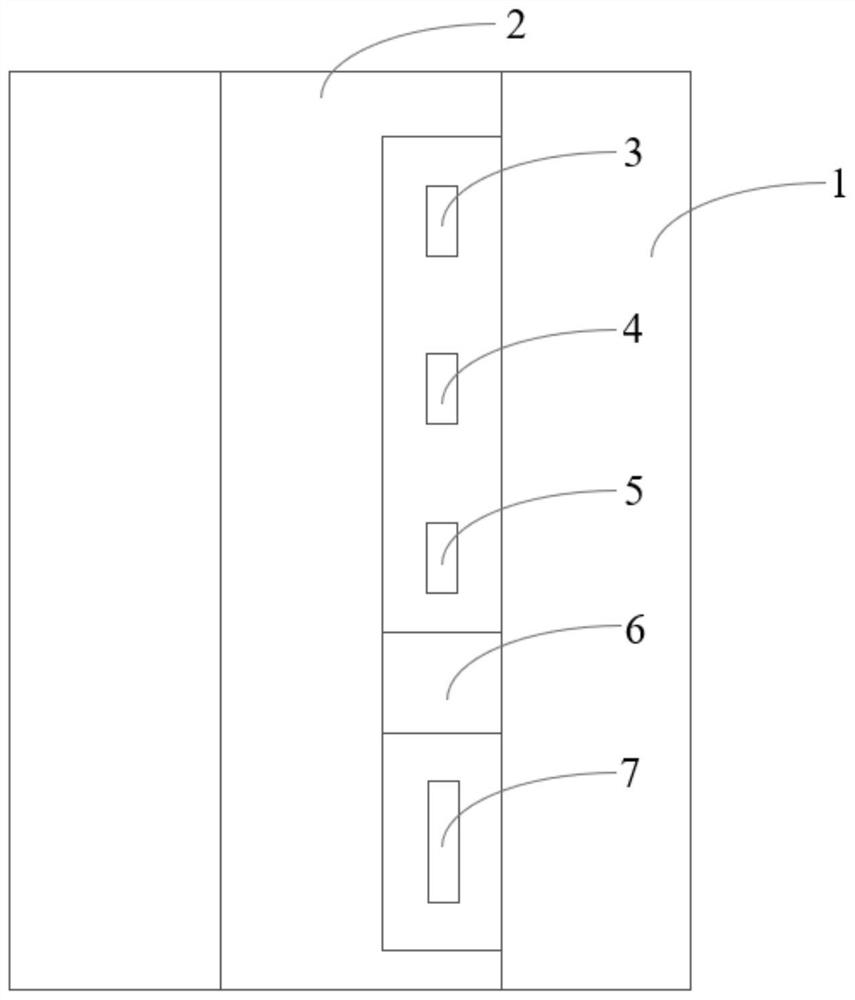

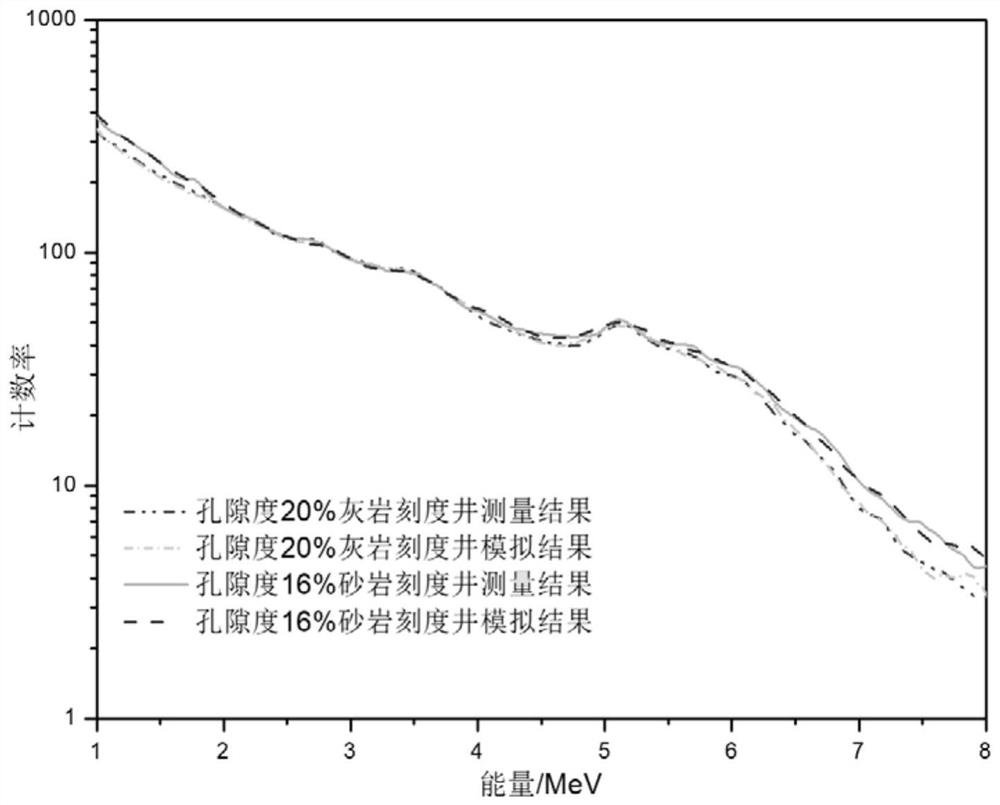

[0036] The present invention proposes a porosity measurement method combining element yield and thermal neutron counting ratio, which uses a three-detector pulsed neutron instrument for measurement, such as figure 1 As shown, the three-detector pulsed neutron instrument includes a D-T pulsed neutron generator 7 , a near thermal neutron detector 5 , a far thermal neutron detector 3 and a gamma detector 4 . During the measurement, the D-T pulsed neutron generator 7 generates high-energy fast neutrons with an energy of 14 MeV to the formation. After entering the formation, the high-energy fast neutrons decelerate and diffuse with the atomic nuclei in the formation until they are absorbed. The deceleration ability of the formation is the basis of the neutron porosity logging method. After the fast neutrons are elastically scattered with the nuclei o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com